Thick-film high-antiseptic cathode electrophoretic coating

A cathodic electrophoretic coating, thick film technology, applied in the direction of anti-corrosion coatings, electrophoretic coatings, epoxy resin coatings, etc., can solve the problems of coating film shrinkage, too thin coating film, corrosion resistance decline, etc., to improve anti-corrosion performance, improve Coverage, effect of improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

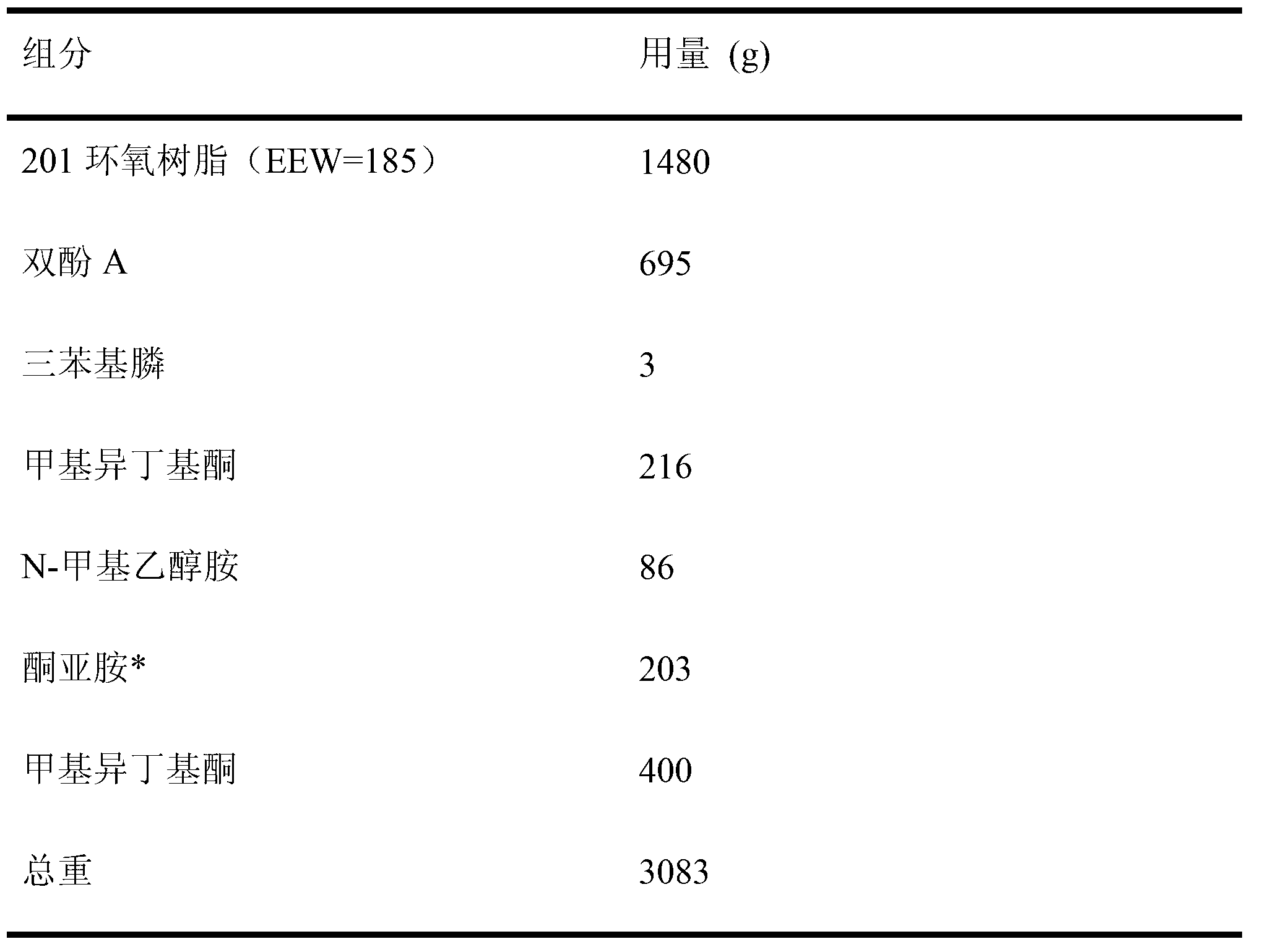

[0018] The preparation of embodiment 1 host resin

[0019]

[0020] * Prepared by the reaction of diethylenetriamine and methyl isobutyl ketone according to the molar ratio of 1:2, the solid content of the final product is: 100%

[0021]In the reaction bottle equipped with thermometer, stirrer and reflux condenser, add the 201 epoxy resin, bisphenol A and the first part of methyl isobutyl ketone of formula quantity successively. After the feeding is completed, start stirring and raise the temperature of the reaction system to 120°C and keep it warm. After the raw materials are completely dissolved and mixed uniformly, add triphenylphosphine and raise the temperature to 150°C, and continue to react at this temperature for 2 hours. When the epoxy equivalent of the system reaches the theoretical value (EEW=1140), stop heating; when the system temperature drops below 90°C, add N-methylethanolamine and ketimine to the reaction system, raise the temperature to 120°C again, and T...

Embodiment 2

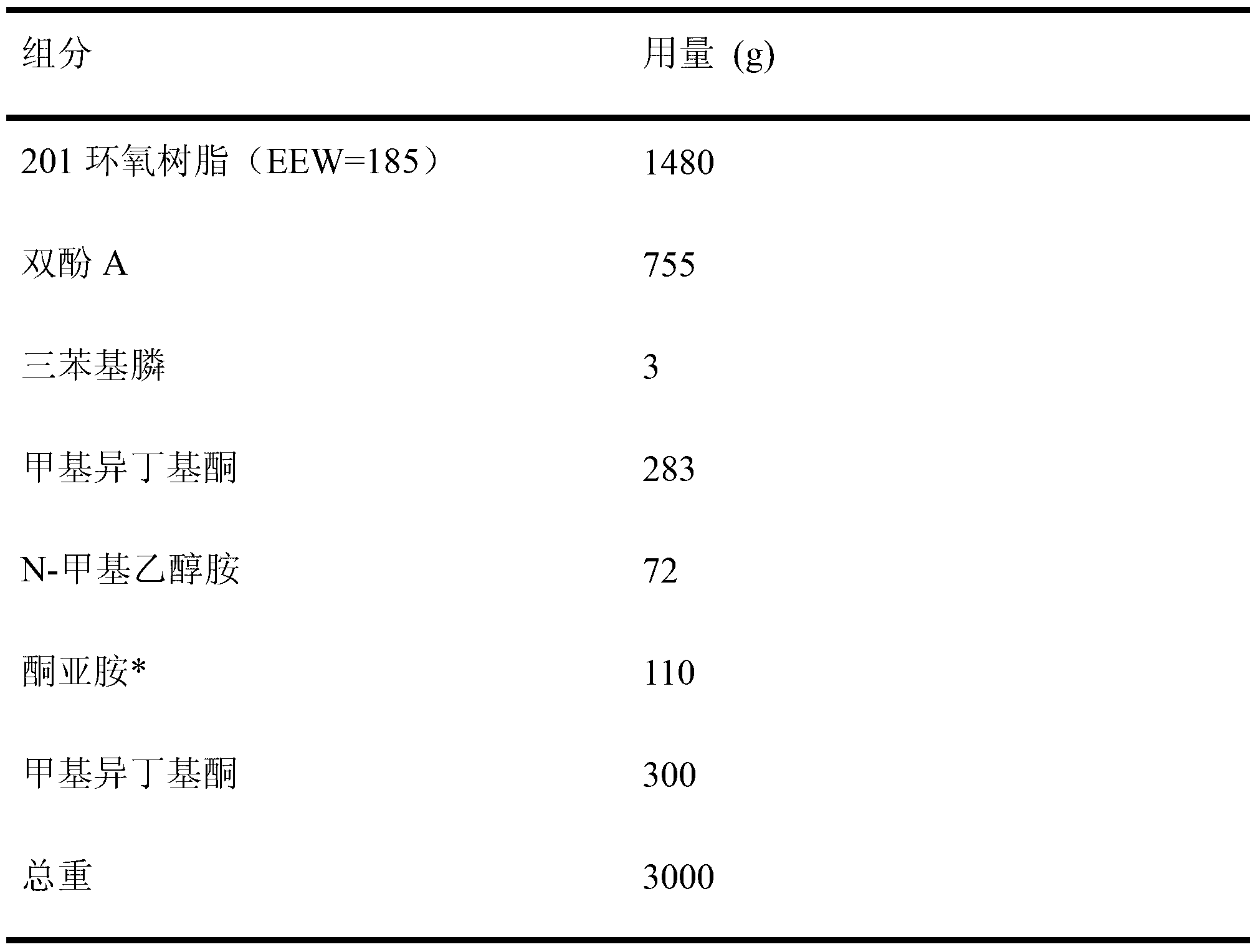

[0022] The preparation of embodiment 2 host resin

[0023]

[0024] * Prepared by the reaction of diethylenetriamine and methyl isobutyl ketone according to the molar ratio of 1:2, the solid content of the final product is: 100%

[0025] In the reaction bottle equipped with thermometer, stirrer and reflux condenser, add the 201 epoxy resin, bisphenol A and the first part of methyl isobutyl ketone of formula quantity successively. After the feeding is completed, start stirring and raise the temperature of the reaction system to 120°C and keep it warm. After the raw materials are completely dissolved and mixed evenly, add triphenylphosphine and raise the temperature to 150°C, and continue to react at this temperature for 3 hours. When the epoxy equivalent of the system reaches the theoretical value (EEW=1600), stop heating; when the system temperature drops below 90°C, add N-methylethanolamine and ketimine to the reaction system, raise the temperature to 120°C again, and The...

Embodiment 3

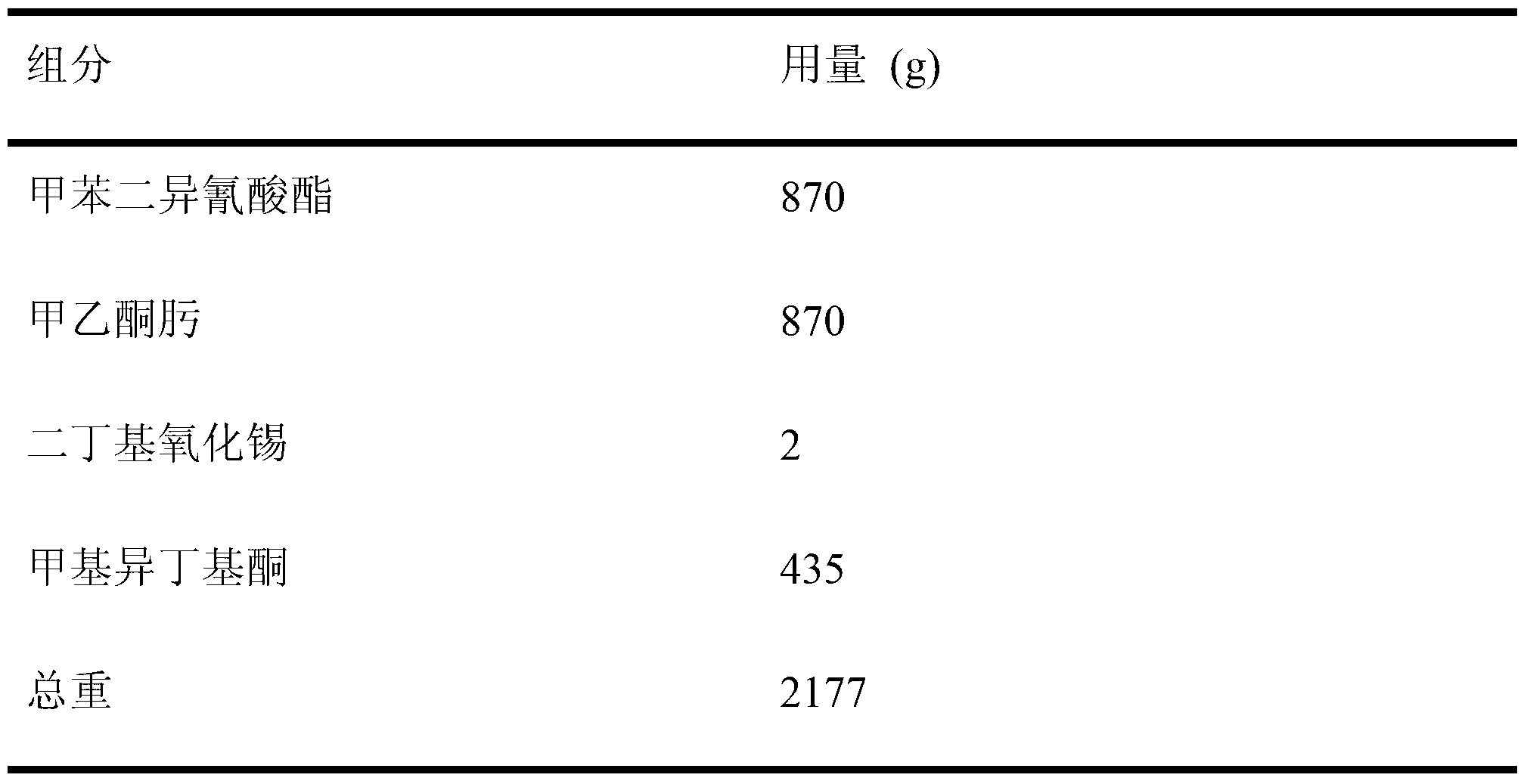

[0026] The preparation of embodiment 3 fully blocked isocyanate crosslinking agent

[0027]

[0028] Add the prescribed amount of toluene diisocyanate and dibutyltin oxide into the reaction flask equipped with a thermometer, agitator and reflux condenser, stir and heat up to 70°C and start to add methyl ethyl ketone oxime dropwise. During the dropwise addition, cool down with a water bath and control The temperature does not exceed 75°C. After the dropwise addition, continue to react at 70°C for 2 hours. Use the standard di-n-butylamine back titration method to analyze the remaining isocyanate content in the reaction system. When the remaining isocyanate content is less than 0.5%, Add methyl isobutyl ketone for dilution to obtain a fully blocked isocyanate crosslinking agent with a final solid content of 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com