Processing equipment and processing method for methyldopa sewage

A technology of methyldopa and treatment equipment, applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve complex water quality, many types of organic matter, high organic pollution, etc. problem, to achieve the effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

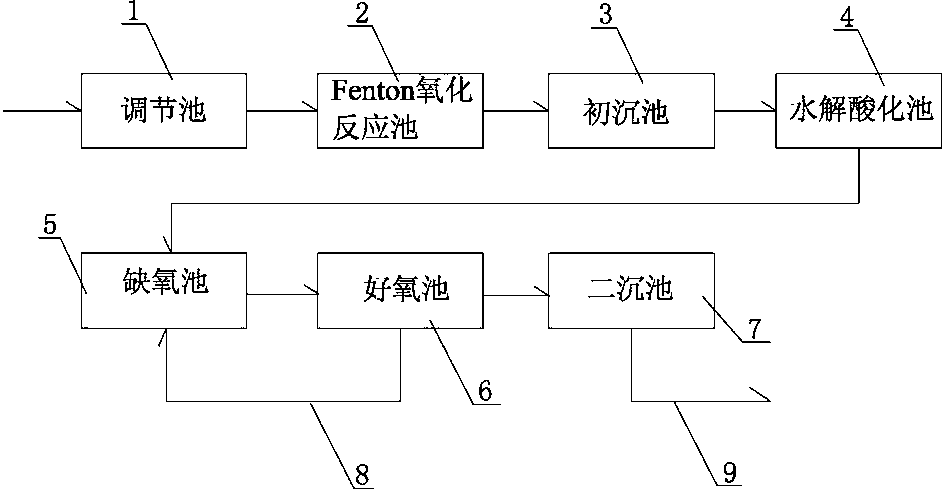

[0023] Please refer to the attached figure 1 Shown, the present invention is a kind of treatment equipment of methyldopa waste water, and it is made of regulating tank 1, Fenton oxidation reaction tank 2, primary sedimentation tank 3, hydrolytic acidification tank 4, anoxic tank 5, aerobic tank 6 and two Several parts such as sinking pool 7 are formed.

[0024] Wherein, the regulating tank 1, the Fenton oxidation reaction tank 2, the primary sedimentation tank 3, the hydrolytic acidification tank 4, the anoxic tank 5, the aerobic tank 6 and the secondary sedimentation tank 7 are connected in sequence to form an integrated processing equipment.

[0025] A sludge return pipe 8 is provided at the bottom of the aerobic pool 6, and the sludge return pipe 8 is connected to the anoxic pool 5, so that the remaining sludge at the bottom of the aerobic pool 6 is discharged into the anoxic pool 5, so that Effective denitrification treatment.

[0026] A sludge discharge pipe 9 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com