Method for extracting scandium oxide from zirconium oxychloride waste acid

A technology of zirconium oxychloride and scandium oxide, which is applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of difficult extraction and separation of scandium, unfavorable industrialization, and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

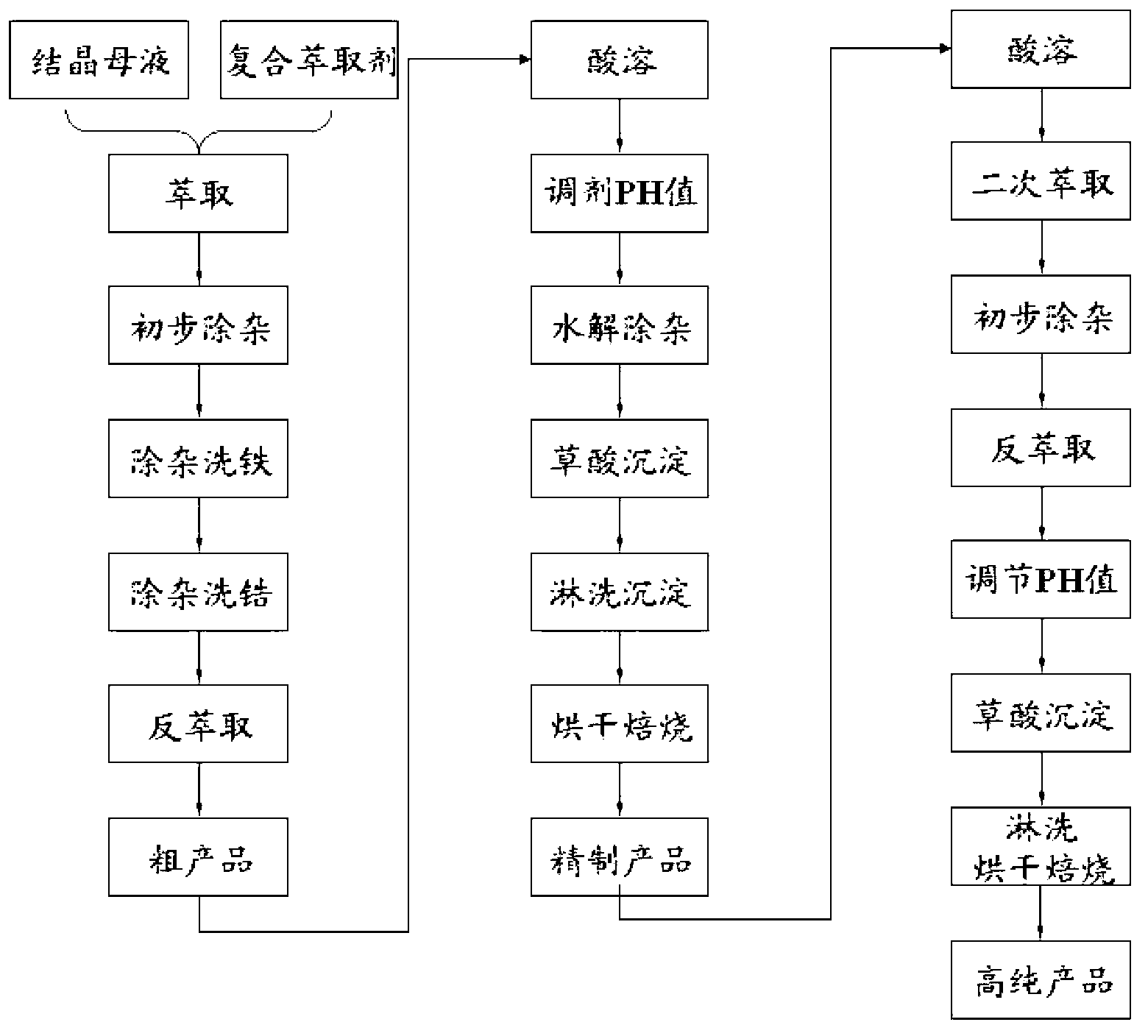

Method used

Image

Examples

Embodiment 1

[0070] 1.1 According to the ratio of P2045wt%, tributyl phosphate 3wt%, sec-octanol 0.5wt%, and the balance of sulfonated kerosene, the extraction agent I was prepared.

[0071] 1.2 Adjust the acidity of the zirconium oxychloride waste acid to 2.5mol / L, the content of scandium ions is 538ppm, and extract with the mass ratio of the zirconium oxychloride waste acid and the extraction agent I obtained in 1.1 as 3:1 , the stirring speed was 250rpm, the mixing time was 5min, and then stood still for 40min. After layering, the oil and water were separated and the remaining liquid was discharged to obtain the organic phase I.

[0072] 1.3 Use water as the washing liquid, stir and wash according to the mass ratio of the organic phase I obtained in 1.2 and the washing liquid at a ratio of 1:1, the stirring speed is 200rpm, the stirring time is 6min, and then stand for 35min, after layering The oil and water are separated and the remaining liquid is discharged to obtain the organic phas...

Embodiment 2

[0089] 2.1 According to the ratio of P20415wt%, tributyl phosphate 7wt%, isooctyl alcohol 1wt%, and the balance of sulfonated kerosene, the extraction agent I was prepared.

[0090] 2.2 the acidity of zirconium oxychloride waste acid is adjusted to 3mol / L, and the content of scandium ion is 800ppm, and the mass ratio of extraction agent I obtained in zirconium oxychloride waste acid and 2.1 is the ratio of 5:1 to extract, The stirring speed was 180 rpm, the mixing time was 18 minutes, and then stood still for 60 minutes. After separation, the oil and water were separated and the residual liquid was discharged to obtain the organic phase I.

[0091] 2.3 Use the hydrofluoric acid solution with a concentration of 0.3wt% as the washing solution, and perform stirring and washing according to the ratio of the organic phase I obtained in 2.2 to the washing solution mass ratio of 1:1, the stirring speed is 120rpm, and the stirring time is 5min , and then left to stand for 45min, after...

Embodiment 3

[0103] 3.1 According to the ratio of P204 10wt%, tributyl phosphate 3wt%, isooctyl alcohol 1.5wt%, and the balance of sulfonated kerosene, the extraction agent I was prepared.

[0104]3.2 the acidity of zirconium oxychloride waste acid is adjusted to 5mol / L, and the content of scandium ion is 2000ppm, and the mass ratio of extraction agent I obtained in zirconium oxychloride waste acid and 3.1 is the ratio of 1:1 to extract, The stirring speed was 300 rpm, the mixing time was 5 minutes, and then stood still for 60 minutes. After layering, the oil and water were separated and the remaining liquid was discharged to obtain the organic phase I.

[0105] 3.3 Use the hydrofluoric acid solution with a concentration of 0.8wt% as the washing solution, and perform stirring and washing according to the mass ratio of the organic phase I obtained in 3.2 and the washing solution at a ratio of 3:1, the stirring speed is 240rpm, and the stirring time is 15min , and then let it stand for 50 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com