Continuous polymer film production method, polymer film, lamda/4 plate, polarizing plate, and liquid crystal display device

A technology of a polymer film and a manufacturing method, which is applied to polarizing elements, flat products, instruments, etc., can solve the problems of skew and easy breakage, and achieve the effect of suppressing the occurrence of skew or breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

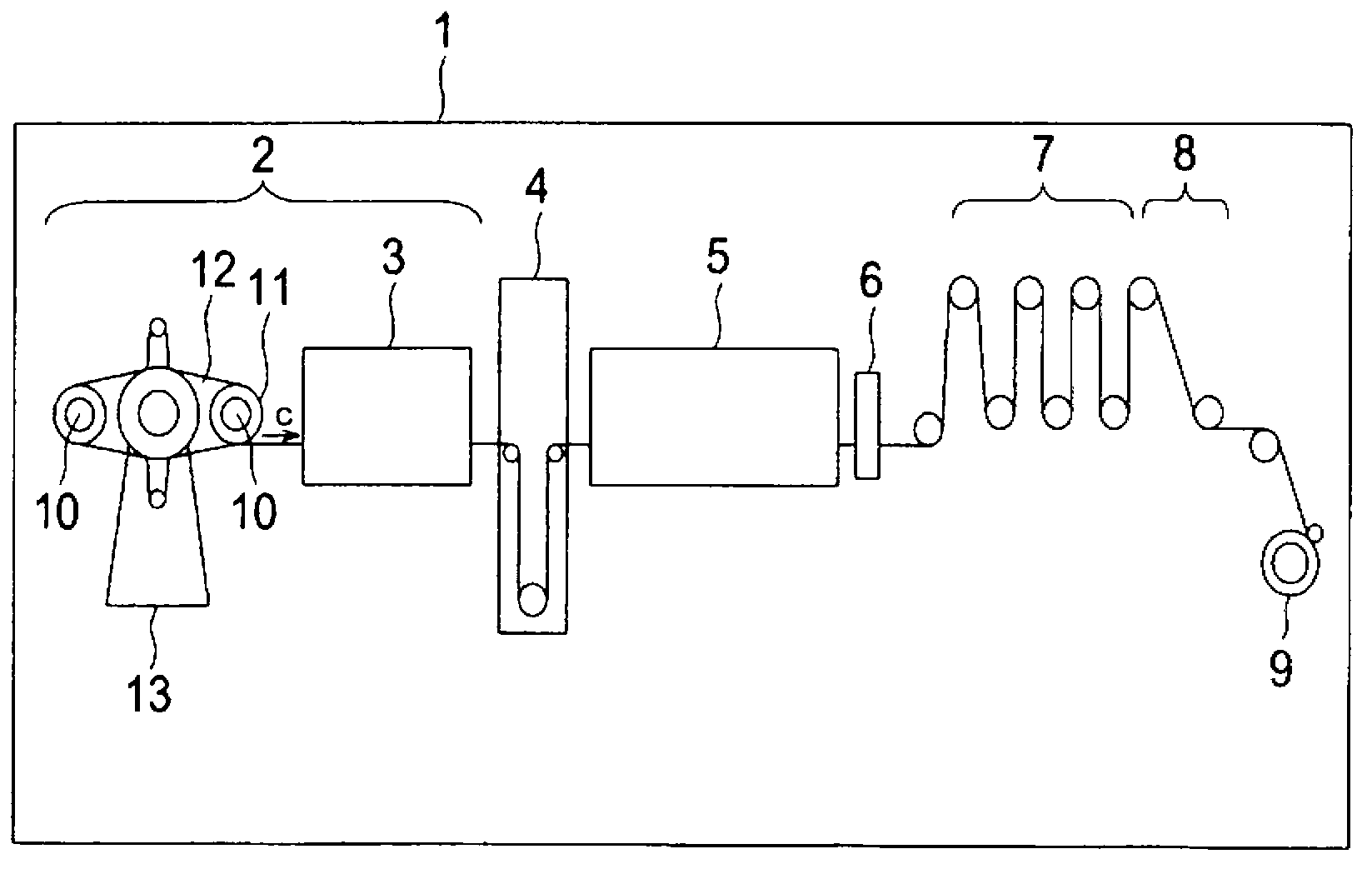

[0324] The raw film used in the present invention can be produced by either a solution casting film forming method or a melt casting film forming method. Hereinafter, a solution casting film forming method of a cellulose ester film will be described as a typical example.

[0325] The production of cellulose ester film is carried out through the following steps: the process of dissolving cellulose ester and additives such as the above-mentioned plasticizer in a solvent to prepare a slurry; casting the slurry on a belt-shaped or drum-shaped metal support The process of drying the flow-cast slurry as a wet film; the process of peeling off the metal support; the process of stretching; the process of further drying; the process of further heat-treating the obtained film as required; The process of winding after cooling. The cellulose ester film used in the present invention preferably contains 60 to 95% by mass of cellulose ester in solid content.

[0326] The steps of preparing ...

manufacture example 1

[0419]

[0420] (making of polyester A)

[0421] Under a nitrogen atmosphere, 4.85 g of dimethyl terephthalate, 4.4 g of 1,2-propanediol, 6.8 g of p-toluic acid, and 10 mg of tetraisopropyl titanate were mixed and stirred at 140° C. for 2 hours. It was further stirred at 210° C. for 16 hours. Next, the temperature was lowered to 170°C, and unreacted 1,2-propanediol was distilled off under reduced pressure to obtain polyester A. Polyester A uses 2 times the molar amount of monocarboxylic acid relative to dicarboxylic acid, so the terminal becomes toluate.

[0422] Acid value: 0.1

[0423] Number average molecular weight: 490

[0424] Dispersion: 1.4

[0425] Concentration of ingredients with a molecular weight of 300 to 1800: 90%

[0426] Hydroxyl value: 0.1

[0427] Hydroxyl content: 0.04%

[0428]

[0429] Microparticles (Aerosil R812 manufactured by Aerosil Japan): 11 parts by mass

[0430] Ethanol: 89 parts by mass

[0431] After stirring and mixing the above s...

manufacture example 2

[0451]

[0452] In Production Example 1, except that the cellulose ester was changed to cellulose acetate propionate having an acetyl group substitution degree of 1.5, a propionyl group of 0.9, and a total substitution degree of 2.4, the same procedure as in Production Example 1 was performed to obtain a roll-shaped Original film 2.

[0453] The average dry film thickness of the obtained raw film 2 was 76 micrometers, the thickness nonuniformity in the longitudinal direction was 0.15 micrometers, and the thickness nonuniformity in the width direction was 0.15 micrometers. In addition, the in-plane retardation value Ro(550) at a wavelength of 550nm was 10nm, and the retardation value Rt(550) in the thickness direction was 118nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com