Method for preparing reduced-oxidized graphene/Fe3O4/Ag nano composite wave-absorbing material

A nano-composite and wave-absorbing material technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of harsh preparation conditions, difficult large-scale production, and complicated processes of composite materials, and achieve good wave-absorbing performance and wave-absorbing properties. The effect of wide frequency band and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

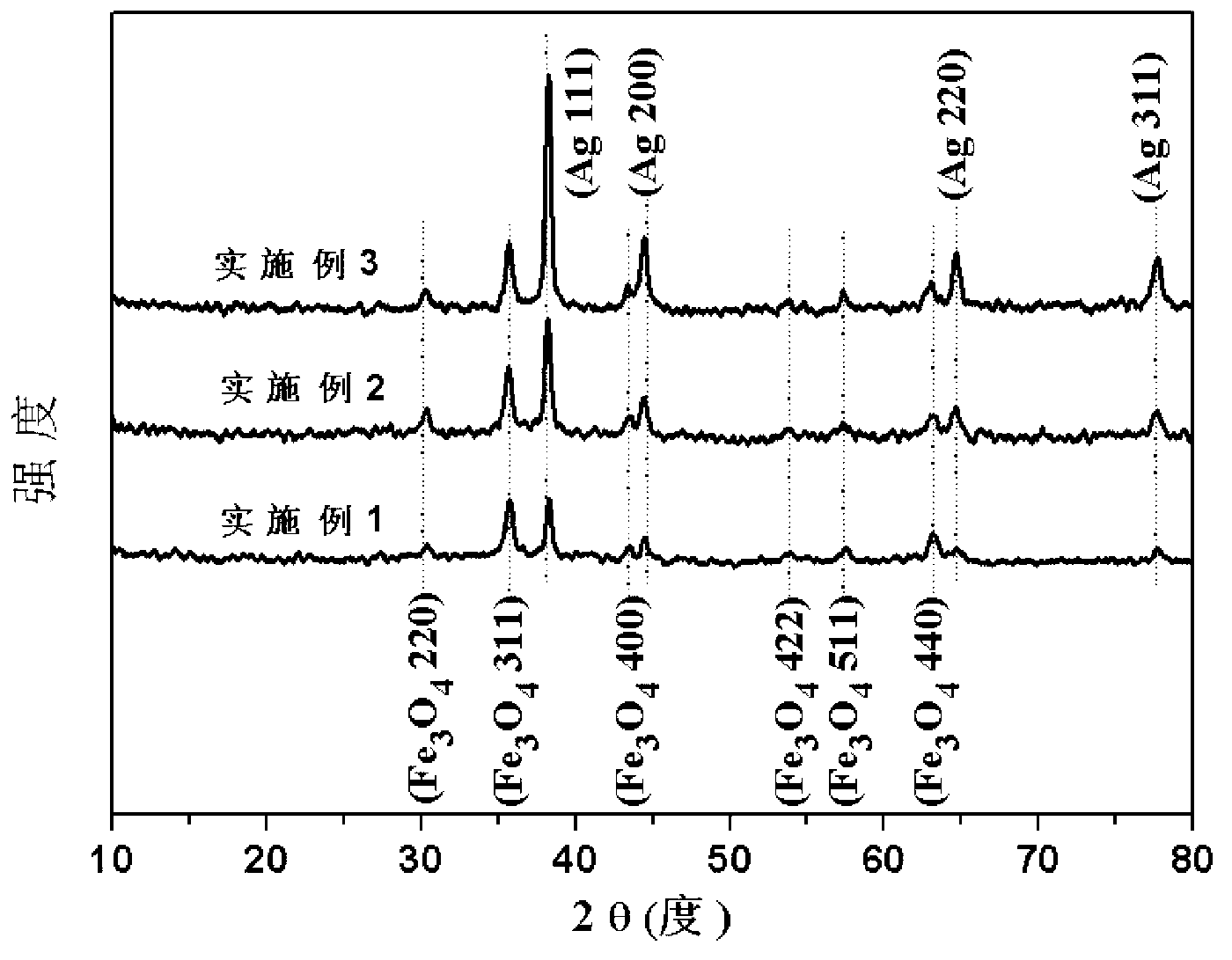

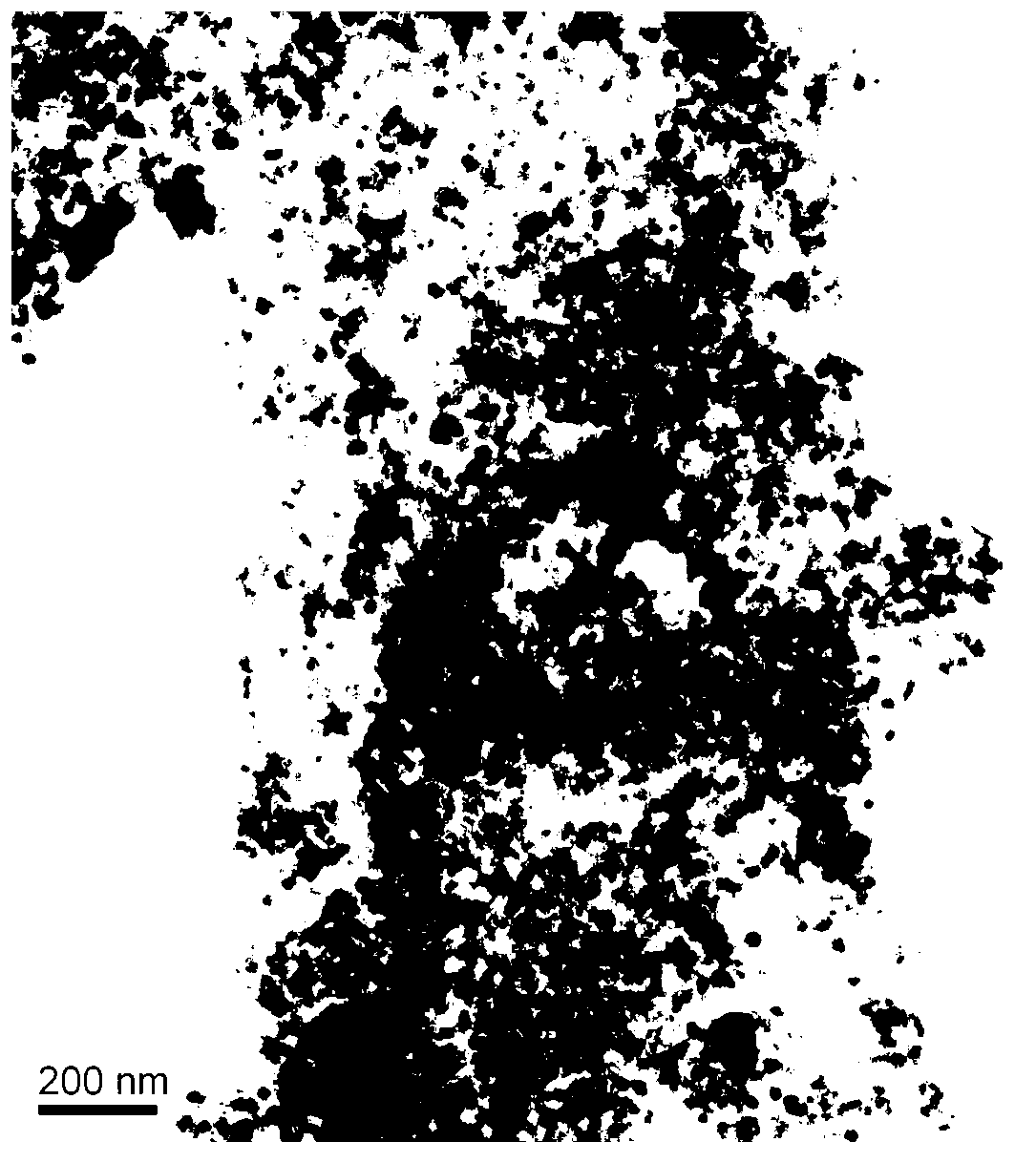

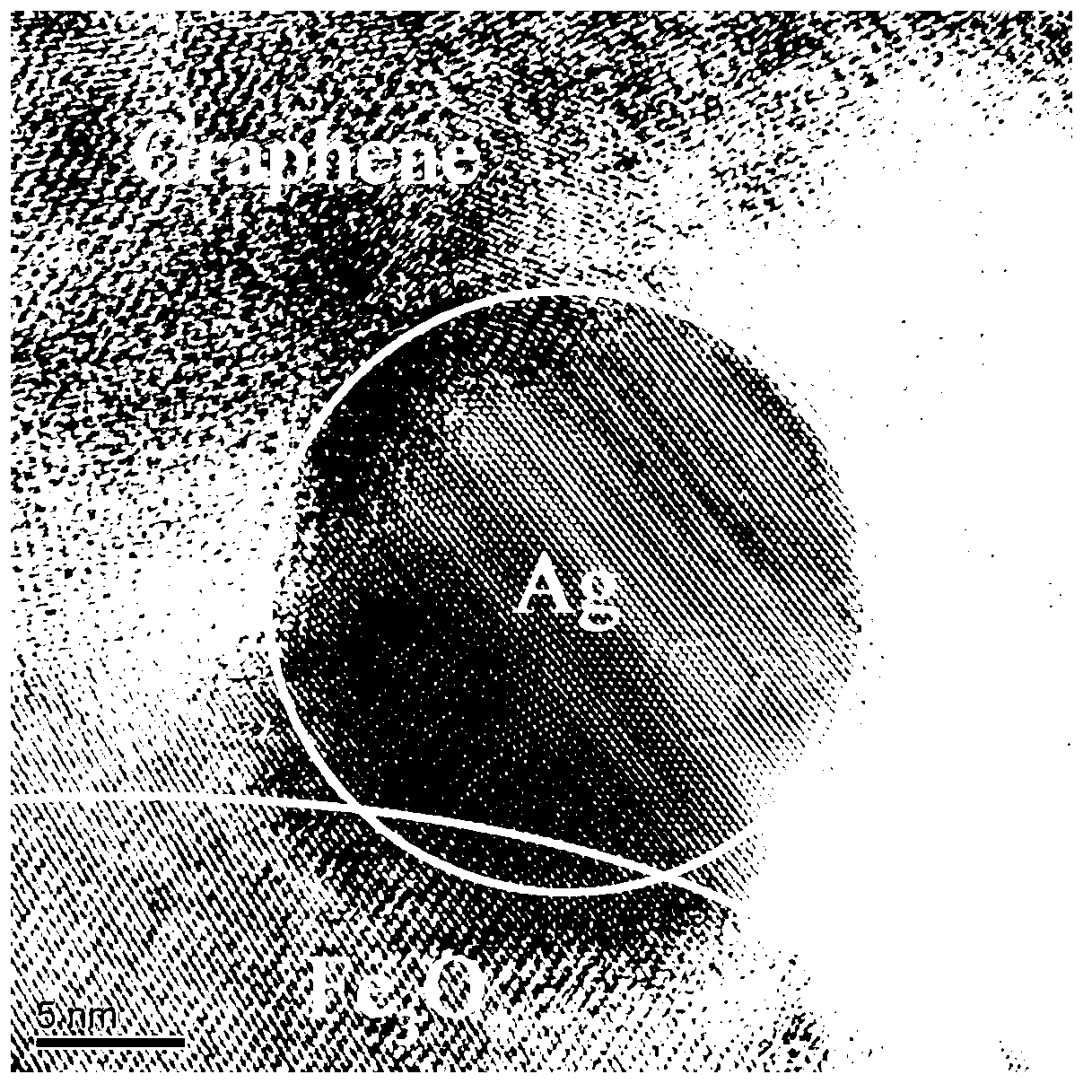

Embodiment 1

[0027] 1. Prepare a GO aqueous solution with a concentration of 0.5mg / ml, and a 1mol / L NaOH aqueous solution for later use;

[0028] 2. According to the mass ratio of GO:FeCl 2 4H 2 O:FeCl 3 ·6H 2 O=1:2.58:3.52 weigh 258mg FeCl 2 4H 2 O and 352 mg FeCl 3 ·6H 2 O, added to 200ml GO aqueous solution, heated in a water bath to 50°C for 10min, added NaOH solution dropwise to adjust the pH of the mixture to 11, and heated the mixture at 70°C for 3h;

[0029] 3. Wash the obtained black precipitate with deionized water for 3-5 times by centrifugal washing method, and then dissolve it in 200ml deionized water. According to the mass ratio of GO:AgNO 3 =1:0.79, weigh 79mg AgNO 3 Dissolve in the above mixture, stir for 20min, according to the mass ratio GO:NaBH 4 =1:10 Weigh 1g NaBH 4 Dissolve in 50ml of water, drop into the mixture, heat at 80°C for 2h;

[0030] 4. Use deionized water and absolute ethanol to wash alternately until pH = 7, use magnetic separation to obtain a b...

Embodiment 2

[0033] 1. Prepare a GO aqueous solution with a concentration of 0.5mg / ml, and a 1mol / L NaOH aqueous solution for later use;

[0034] 2. According to the mass ratio of GO:FeCl 2 4H 2 O:FeCl 3 ·6H 2 O=1:2.58:3.52 weigh 258mg FeCl 2 4H 2 O and 352 mg FeCl 3 ·6H 2 O, added to 200ml GO aqueous solution, heated in a water bath to 50°C for 10min, added NaOH solution dropwise to adjust the pH of the mixture to 11, and heated the mixture at 70°C for 3h;

[0035] 3. Wash the obtained black precipitate with deionized water for 3-5 times by centrifugal washing method, and then dissolve it in 200ml deionized water. According to the mass ratio of GO:AgNO 3 =1:1.58, weigh 158mg AgNO 3 Dissolve in the above mixture, stir for 20min, according to the mass ratio GO:NaBH 4 =1:10 Weigh 1g NaBH 4 Dissolve in 50ml of water, drop into the mixture, heat at 80°C for 2h;

[0036] 4. Use deionized water and absolute ethanol to wash alternately until pH = 7, use magnetic separation to obtain a ...

Embodiment 3

[0040] 1. Prepare a GO aqueous solution with a concentration of 0.5mg / ml, and a 1mol / L NaOH aqueous solution for later use;

[0041] 2. According to the mass ratio of GO:FeCl 2 4H 2 O:FeCl 3 ·6H 2 O=1:2.58:3.52 weigh 258mg FeCl 2 4H 2 O and 352 mg FeCl 3 ·6H 2 O, added to 200ml GO aqueous solution, heated in a water bath to 50°C for 10min, added NaOH solution dropwise to adjust the pH of the mixture to 11, and heated the mixture at 70°C for 3h;

[0042] 3. Wash the obtained black precipitate with deionized water for 3-5 times by centrifugal washing method, and then dissolve it in 200ml deionized water. According to the mass ratio of GO:AgNO 3 =1:3.15, weigh 315mg AgNO 3 Dissolve in the above mixture, stir for 20min, according to the mass ratio GO:NaBH 4 =1:10 Weigh 1g NaBH 4 Dissolve in 50ml of water, drop into the mixture, heat at 80°C for 2h;

[0043] 4. Use deionized water and absolute ethanol to wash alternately until pH = 7, use magnetic separation to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com