Anti-aging agent of static cable

An anti-aging agent and technology of anti-aging agent, applied in the field of high-efficiency anti-aging agent and its preparation, can solve the problem of not fully achieving comprehensive protection and the like, and achieve the effects of good practical effect, good anti-atmospheric aging and good anti-ultraviolet effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

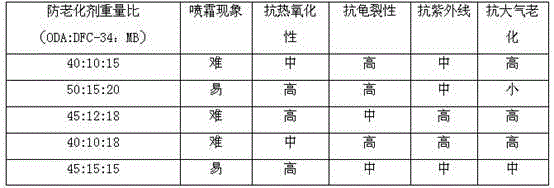

[0018] Embodiment 1: An antiaging agent for a static cable, comprising the following components in parts by weight: 40-50 parts by weight of antiaging agent ODA, 10-15 parts by weight of antiaging agent DFC-34, and 15-20 parts by weight of antiaging agent MB Parts by weight, 0.1-0.3 parts by weight of rubber accelerator, wherein the ratio of parts by weight between anti-aging agent ODA, anti-aging agent DFC-34 and anti-aging agent MB is 4-5:1-1.5:1.5-2; The weight ratio of different components in the anti-aging agent has various ratios, as shown in the table below, the ratio with better practical effect is: the weight parts of anti-aging agent ODA, anti-aging agent DFC-34 and anti-aging agent MB The ratio is 40:10:18.

[0019]

[0020] The anti-aging agent ODA of the present invention is the reaction product of diphenylamine and diisobutylene, which has a good anti-atmospheric aging effect. The anti-aging agent DFC-34 is 34% styrenated diphenylamine condensate+66% Light ca...

Embodiment 2

[0021] Embodiment 2: the elastic carrier of the present invention is one or more mixtures in natural rubber, styrene-butadiene rubber, nitrile rubber, neoprene rubber, and the preferred elastic carrier is 8-12 parts by weight, and the elastic carrier is used It is used to assist the mixing and adhesion of various anti-aging agents.

[0022] The dispersant of the present invention is one or two mixtures in liquid paraffin and microcrystalline wax, and the preferred dispersant is 1-5 parts by weight, and the dispersion effect of the elastic carrier and antiaging agent mixture is improved by the dispersant, because Static cables require greater strength, so stearic acid is not used as a dispersant.

[0023] The ratio of parts by weight of the elastic carrier of the present invention to the rubber accelerator is 10:0.2, and the rubber accelerator is used to improve the modulus stress of the carrier, which can ensure the molding effect of the fixed particles of the anti-aging agent...

Embodiment 3

[0024] Embodiment 3: a kind of preparation steps of anti-aging agent of static cable:

[0025] 1) After mixing anti-aging agent ODA, anti-aging agent DFC-34 and anti-aging agent MB in sequence, heat, melt and stir under reduced pressure and low temperature, and the temperature does not exceed 50°C; since anti-aging agent DFC-34 is a solid mixture, it contains 33% light calcium is prone to side reactions under high temperature conditions, and it is melted by heating under reduced pressure.

[0026] 2) Heat and melt the elastic carrier at the same time, add heated rubber oil and rubber accelerator and stir for 30 minutes to react; this reaction is also carried out under the condition of vacuum and decompression.

[0027] 3) Add the mixed extended elastic carrier to the anti-aging agent mixture while it is hot, and add the dispersant while stirring, react for 1 hour, gradually reduce the reaction temperature, and cool to form a solid mixture.

[0028] 4) Stir the cooled mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com