Preparation method of epoxy functional core-shell structure magnetic polymer microsphere

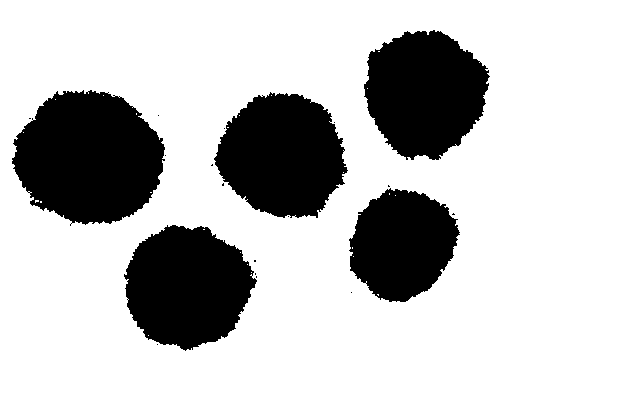

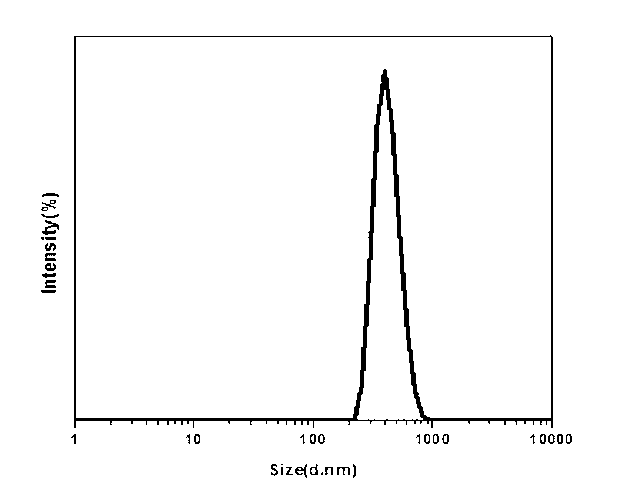

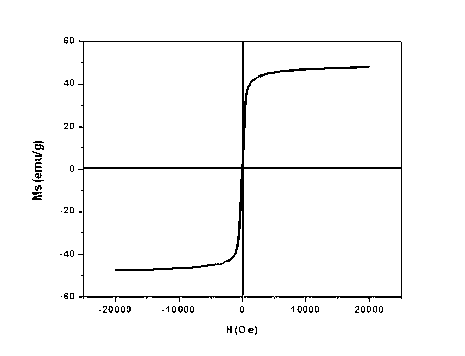

A core-shell structure, epoxy function technology, applied in the field of functional materials, can solve the problems of cumbersome preparation process, time-consuming, multiple steps, etc., and achieve the effect of simple preparation process, narrow particle size distribution and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 To prepare magnetic polymer microspheres with a shell thickness of about 20 nm and a magnetic core particle size of about 300 nm, the specific steps are as follows:

[0023] The first step: preparation of polyethylene glycol (MW 1000) stabilized Fe3O4 nanoclusters

[0024] Take 1.5 g of iron sulfate (Fe 2 (SO 4 ) 3 ), 1.6 g of polyethylene glycol (PEG), 3.4 g of potassium acetate (KAc), dissolved in 70 ml of ethylene glycol, and then transferred to a 250 ml three-necked flask, mechanically stirred at room temperature for 1 h , the liquid in the flask was transferred to a high-pressure reactor with a capacity of 100 ml and lined with polytetrafluoroethylene, and then the reactor was placed in an oven at 180 °C for 12 h and then taken out, and cooled rapidly with tap water to At room temperature, the product is finally washed by magnetic separation, and unreacted reactants are removed by washing with absolute ethanol and deionized water, respectively, unt...

Embodiment 2

[0029] Example 2 Prepare magnetic polymer microspheres with a shell thickness of about 50 nm and a magnetic core particle size of about 300 nm. The specific steps are as follows:

[0030] The first step: the preparation of polyethylene glycol (MW 1000) stabilized Fe3O4 nanocrystal clusters is the same as that described in the first step of Example 1;

[0031] The second step: the double bond functional group on the surface of the ferroferric oxide nanocrystal cluster is the same as that described in the second step of Embodiment 1;

[0032] The third step: the preparation of epoxy functionalized core-shell magnetic polymer microspheres is the same as described in the third step of embodiment 1, the difference is that the consumption of glycidyl acrylate is 2.0 g, and the consumption of divinylbenzene is 500 mg and 50 mg of azobisisoheptanonitrile.

Embodiment 3

[0033] Example 3 Prepare magnetic polymer microspheres with a shell thickness of about 20 nm and a magnetic core particle size of about 200 nm. The specific steps are as follows:

[0034] The first step: preparation of sodium citrate-stabilized Fe3O4 nanocrystal clusters

[0035] Take 4.5 g of ferric chloride hexahydrate (FeCl 3 ·H 2 O), 1.5 g sodium citrate, 10 g sodium acetate (NaAc), dissolved in 100 ml of ethylene glycol, and then transferred to a 150 ml three-necked flask, mechanically stirred at 160 ° C for 6 h, the flask The liquid in the solution was transferred into a 150 ml high-pressure reactor with a polytetrafluoroethylene liner, and then the reactor was placed in an oven at 200 °C for 24 h, and then it was taken out and quickly cooled to room temperature with tap water. Finally, the product was washed by magnetic separation, and unreacted reactants were removed by washing with absolute ethanol and deionized water, respectively, until the supernatant was colo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com