Butadiene product and preparation method thereof

A technology of butadiene and vinyl acetylene is applied in the field of butadiene products and their preparation, which can solve the problems such as the preparation method of butadiene needs to be improved, and achieve the effect of reducing production cost and simplifying the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

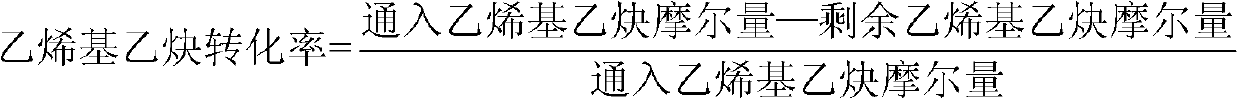

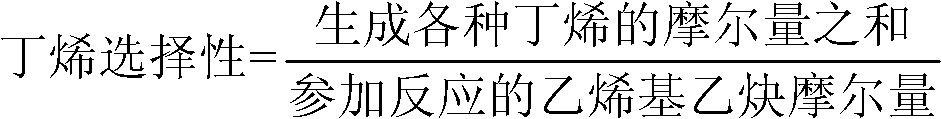

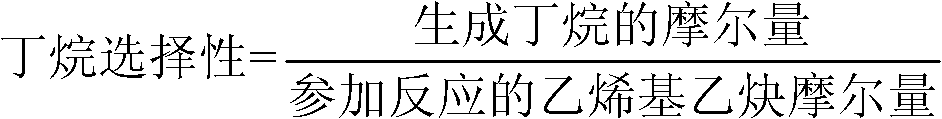

Examples

Embodiment 1

[0020] 4 g of Pd / Al with a loading of 0.1% 2 o 3 The catalyst was loaded into a fixed-bed microreactor, and the temperature of the reactor was maintained at 50° C., wherein the upper and lower layers of the catalyst were lined with quartz sand. Then, the reagent with electron-donating ability—CO gas and vinyl acetylene are mixed at a volume ratio of 0.01:1, and then passed into the reactor under normal pressure conditions, so that vinyl acetylene can undergo hydrogenation reaction to produce butanediene alkene. Wherein, the vinyl acetylene is provided in the form of a mixture of vinyl acetylene and the second gas, and the composition of the mixture is: 30 vol % vinyl acetylene, 30 vol % hydrogen and 40 vol % nitrogen. The space velocity of vinyl acetylene is 100ml·g -1 h -1 .

Embodiment 2

[0022] According to the method of Example 1, butadiene was prepared. Wherein, the difference from Example 1 is that the volume ratio of CO gas to vinyl acetylene is 0.02:1.

Embodiment 3

[0024] According to the method of Example 1, butadiene was prepared. Wherein, the difference from Example 1 is that the volume ratio of CO gas to vinyl acetylene is 0.05:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com