Metal mold gravity casting process for automobile intake pipe

A technology of gravity casting and metal mold, which is applied in the field of casting of mechanical parts, can solve the problems of low mold productivity, inconvenient clamping and disassembly, high mold cost, etc., and achieve the effects of improving pass rate, reducing air holes, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

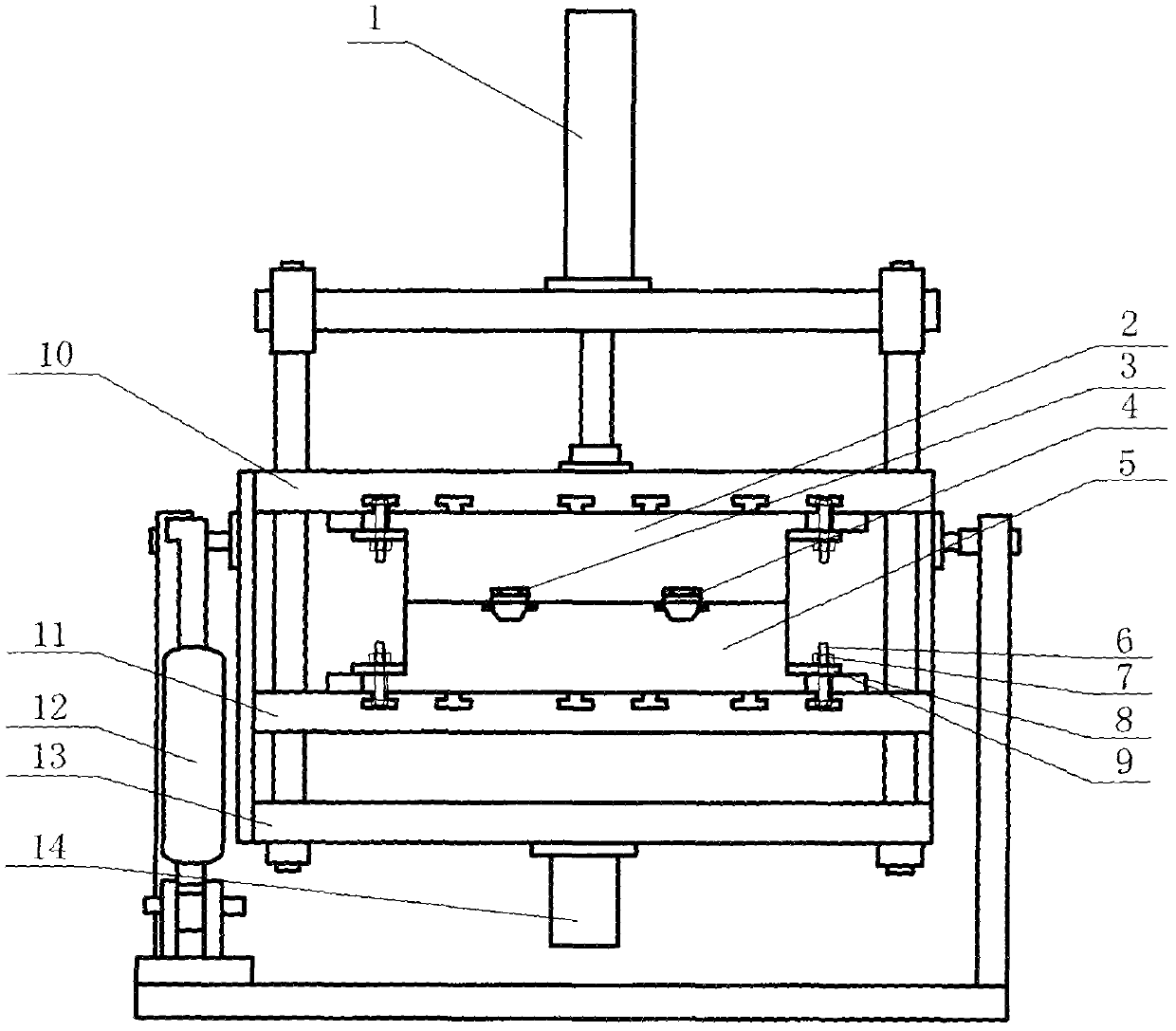

[0019] Embodiment 1, taking the sand core casting of the intake pipe CH001 as an example to illustrate the gravity casting process of the metal mold.

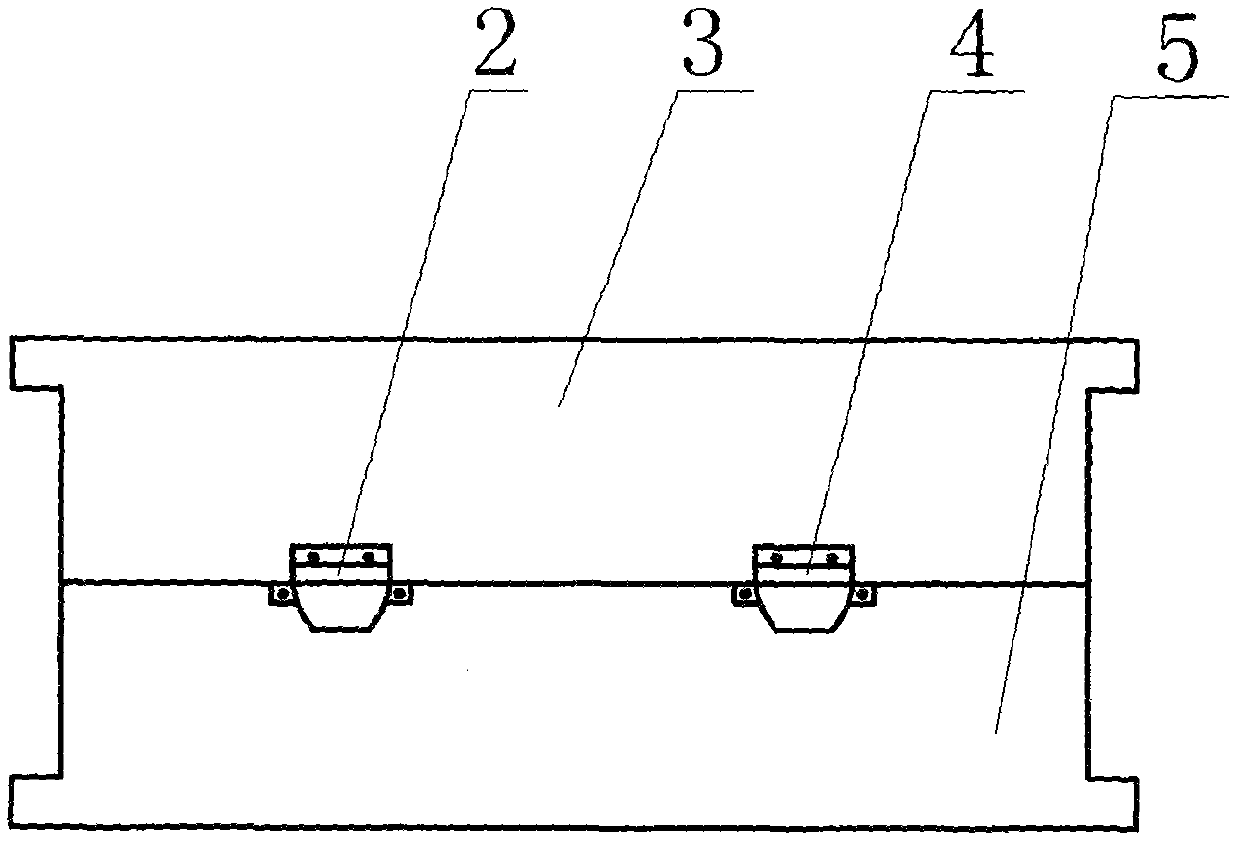

[0020] (1) Mold preheating 1: separate the upper mold 2 and the lower mold 5 of the metal mold and place the heater on the surface of the upper mold 2 and the lower mold 5, bake and preheat to 230 degrees, pour the pot 3 and pour Pots 4 are preheated together.

[0021] (2) Mold spraying: Use dry sand and compressed air to blow out the preheated upper mold 2 and lower mold 5 with an air gun to clean the mold cavity surface. After the mold is cooled to 180°C, spray the coating agent on the metal surface. On the mold, the paint and water are mixed according to the volume ratio of 1:3, and the inner cavity is sprayed to a thickness of 100 microns, and the thickness of the pouring basin 3, the sprue and the riser is increased to 330 microns, and the inner cavity needs to be cooled quickly. Molybdenum disulfide is used to smear the ...

Embodiment 2

[0027] Embodiment 2, taking the casting of steering pump JV348 with sand core as an example to illustrate the metal mold gravity casting process.

[0028] (1) Mold preheating 1: separate the upper mold 2 and the lower mold 5 of the metal mold and place the heater on the surface of the upper mold 2 and the lower mold 5, bake and preheat to 250 degrees, pour the pot 3 and pour Pots 4 are preheated together.

[0029] (2) Mold spraying: Use dry sand and compressed air to blow out the preheated upper mold 2 and lower mold 5 with an air gun to clean the mold cavity surface. After the mold is cooled to 200°C, spray the coating agent on the metal surface. On the mold, the paint and water are mixed according to the volume ratio of 1:5, and the inner cavity is sprayed to a thickness of 120 microns, and the thickness of the pouring basin 3, runner and riser is increased to 350 microns, and the inner cavity needs to be cooled quickly. Molybdenum disulfide is used to smear the parts of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com