Cable groove cover plate

A technology of cable trench cover and cable trench, which is applied in the direction of cable installation, ground cable installation, electrical components, etc., which can solve the problems of heavy workload and achieve the effects of reducing workload, improving safety and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

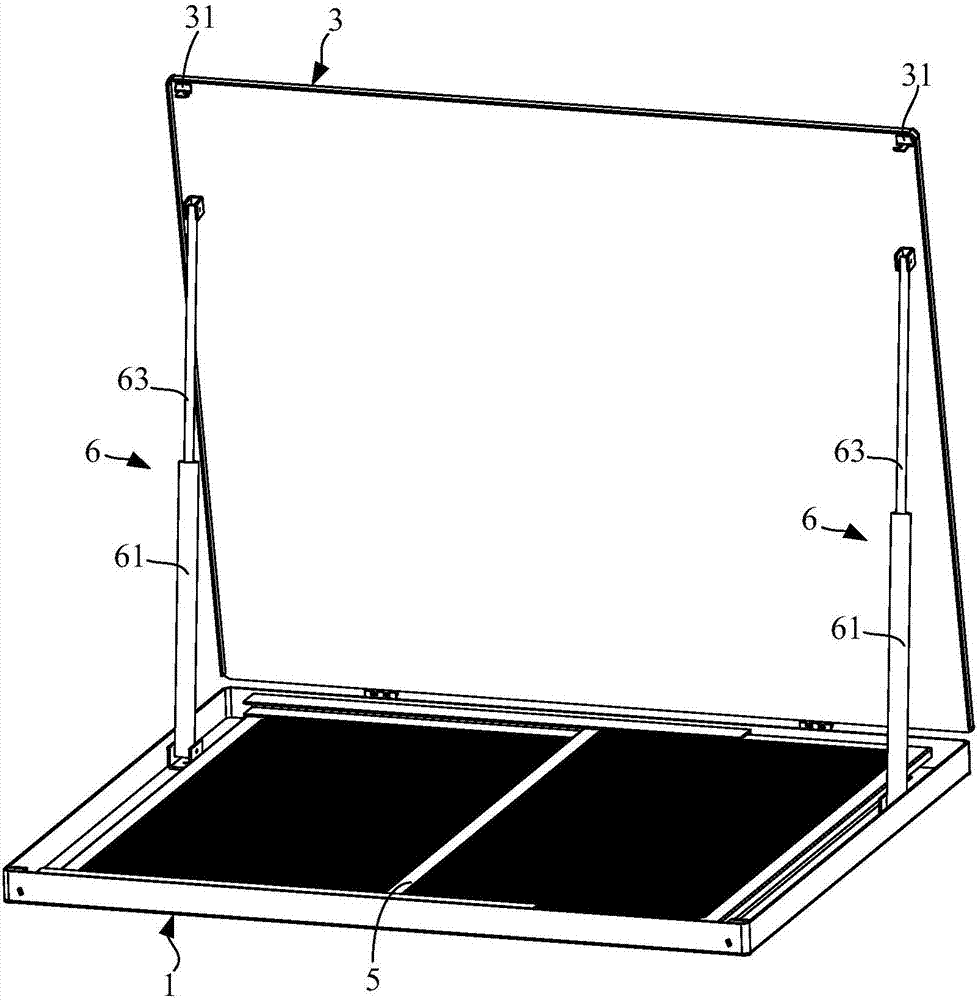

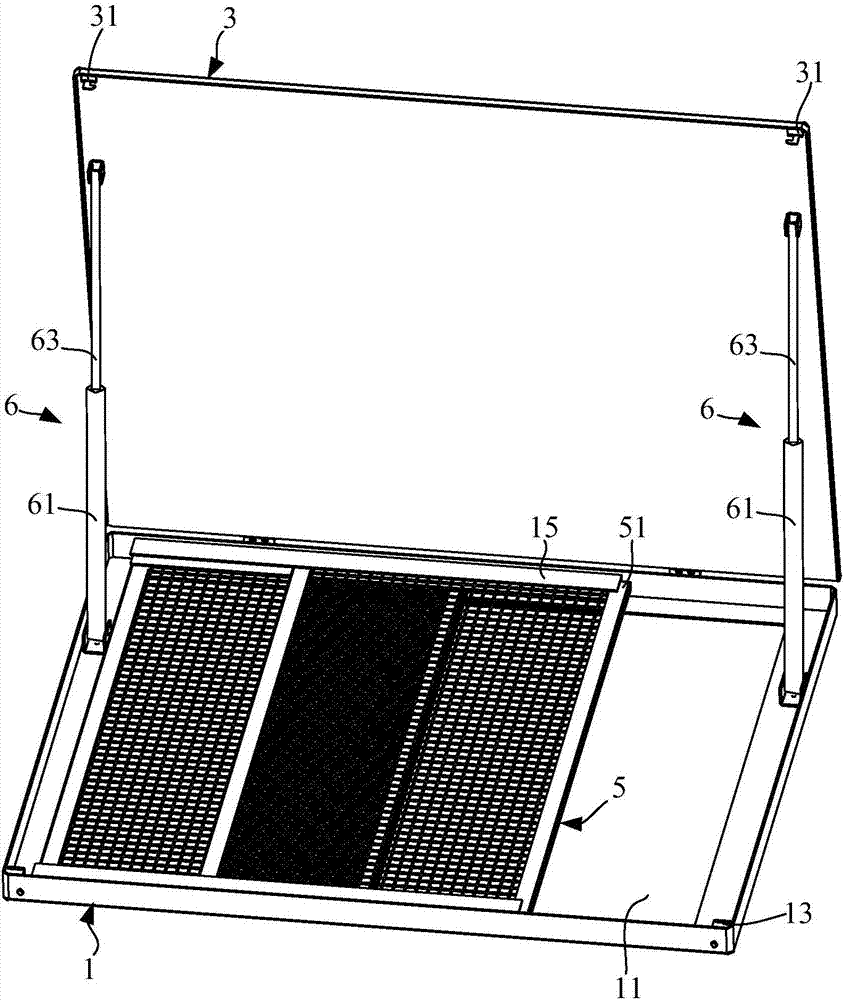

[0032] Such as Figure 1 to Figure 3 As shown, the cable trench cover plate of this embodiment is used to cover the cable trench to protect the cables in the cable trench. The cable trench cover includes a base 1, a protective net 5 and a cover 3 that cooperates with the base 1 and covers the outside of the entire cable trench cover.

[0033] Base 1 cover among the present embodiment is arranged on the cable ditch, has installation opening on it; Protection net 5 is arranged on the installation opening, and protection net 5 includes two sub-protection nets, and at least one sub-protection net can be mounted on the installation opening. It is arranged to move back and forth, and when the movable sub-protection net moves to an overlapping position with another sub-protection net, the installation opening on the base 1 will be opened to form an inspection port 11 that can be used for overhauling the cable trench; the cover plate 3 , cooperate with the base 1 in a hinged manner, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com