A pulverized coal dynamic separator using curved blades

A separator and blade technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of large blade wear, weak airflow, and difficult to filter large coal powder particles, etc. Achieve the effect of improving coal fineness, reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

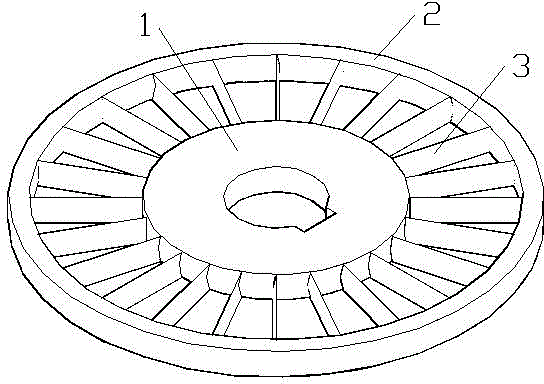

[0024] see figure 1 , Figure 4 to Figure 6 In this embodiment, the pulverized coal dynamic separator using curved blades includes a rotating shaft disc 1, a ring 2 and several blades 3, and the pulverized coal dynamic separator is a rotating planar structure.

[0025] The blade 3 in this embodiment is a curved surface structure, and the blade 3 is provided with a concave surface 31 and a convex surface 32. The concave surface 31 in the blade 3 is arc-shaped, and the convex surface 32 in the blade 3 is semi-elliptical. The two endpoints of the semi-ellipse coincide with the two endpoints of the semi-ellipse respectively, the line between the two endpoints of the semi-ellipse is the major axis of the ellipse, the length of the major axis of the ellipse is the chord length of the arc, and the ellipse The length of the minor axis is 6 / 10 of the radius of the arc.

[0026] The radius of the rotating shaft disc 1 in this embodiment is smaller than the radius of the ring 2, the ro...

Embodiment 2

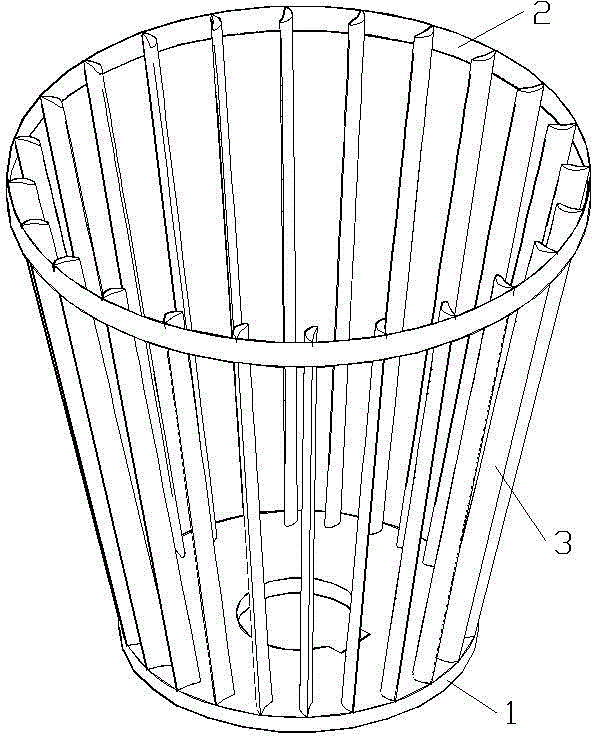

[0033] see figure 2 , Figure 4 to Figure 6 , The pulverized coal dynamic separator using curved blades in this embodiment includes a rotating shaft disk 1, a ring 2 and several blades 3, and the pulverized coal dynamic separator has a conical structure.

[0034] The blade 3 in this embodiment is a curved surface structure, and the blade 3 is provided with a concave surface 31 and a convex surface 32. The concave surface 31 in the blade 3 is arc-shaped, and the convex surface 32 in the blade 3 is semi-elliptical. The two endpoints of the semi-ellipse coincide with the two endpoints of the semi-ellipse respectively, the line between the two endpoints of the semi-ellipse is the major axis of the ellipse, the length of the major axis of the ellipse is the chord length of the arc, and the ellipse The length of the minor axis is 6 / 10 of the radius of the arc.

[0035] The radius of the rotating shaft disc 1 in this embodiment is smaller than the radius of the ring 2, the rotatin...

Embodiment 3

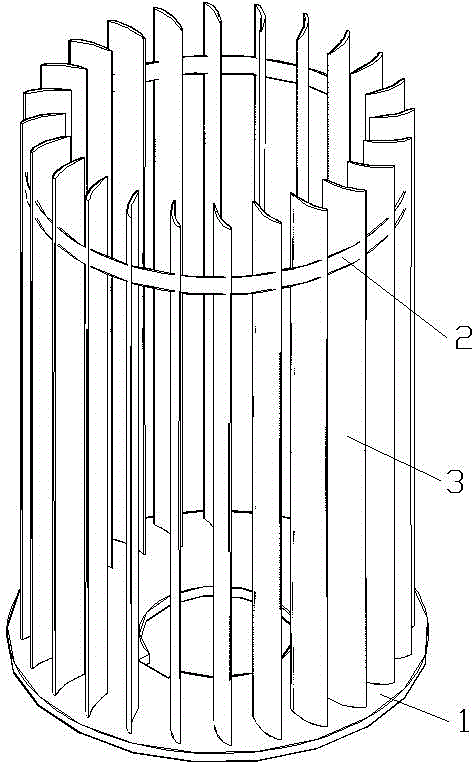

[0038] see Figure 3 to Figure 6 , The pulverized coal dynamic separator using curved blades in this embodiment includes a rotating shaft disc 1, a ring 2 and several blades 3, and the pulverized coal dynamic separator has a cylindrical structure.

[0039] The blade 3 in this embodiment is a curved surface structure, and the blade 3 is provided with a concave surface 31 and a convex surface 32. The concave surface 31 in the blade 3 is arc-shaped, and the convex surface 32 in the blade 3 is semi-elliptical. The two endpoints of the semi-ellipse coincide with the two endpoints of the semi-ellipse respectively, the line between the two endpoints of the semi-ellipse is the major axis of the ellipse, the length of the major axis of the ellipse is the chord length of the arc, and the ellipse The length of the minor axis is 6 / 10 of the radius of the arc.

[0040] The radius of the rotating shaft disc 1 in this embodiment is greater than or equal to the radius of the ring 2, the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com