Device for treating malodorous gas based on capacitive coupling partition discharge plasma

A discharge plasma and capacitive coupling technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of small plasma, poor stability, unevenness, etc., and improve discharge stability and reaction time Short, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

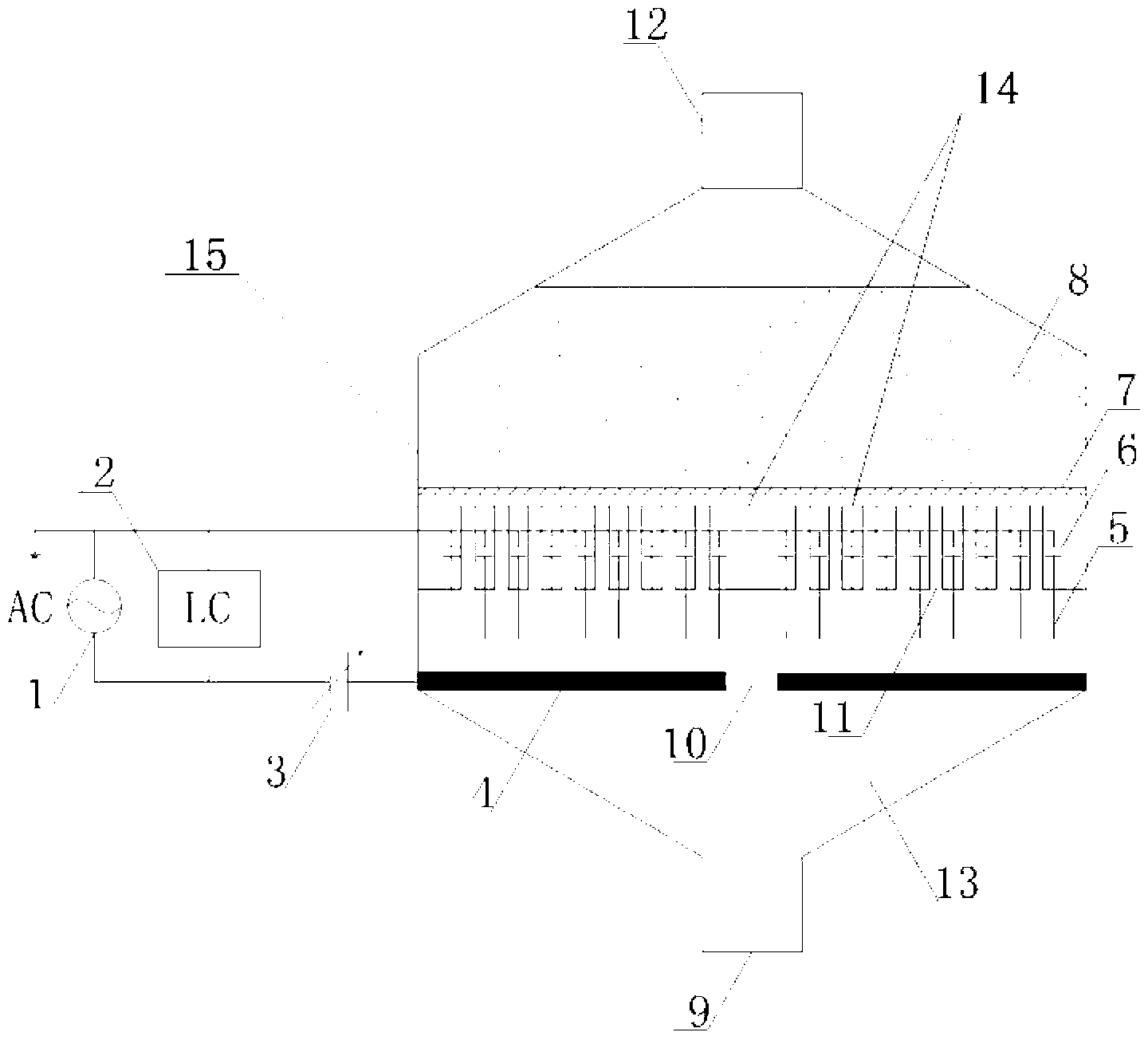

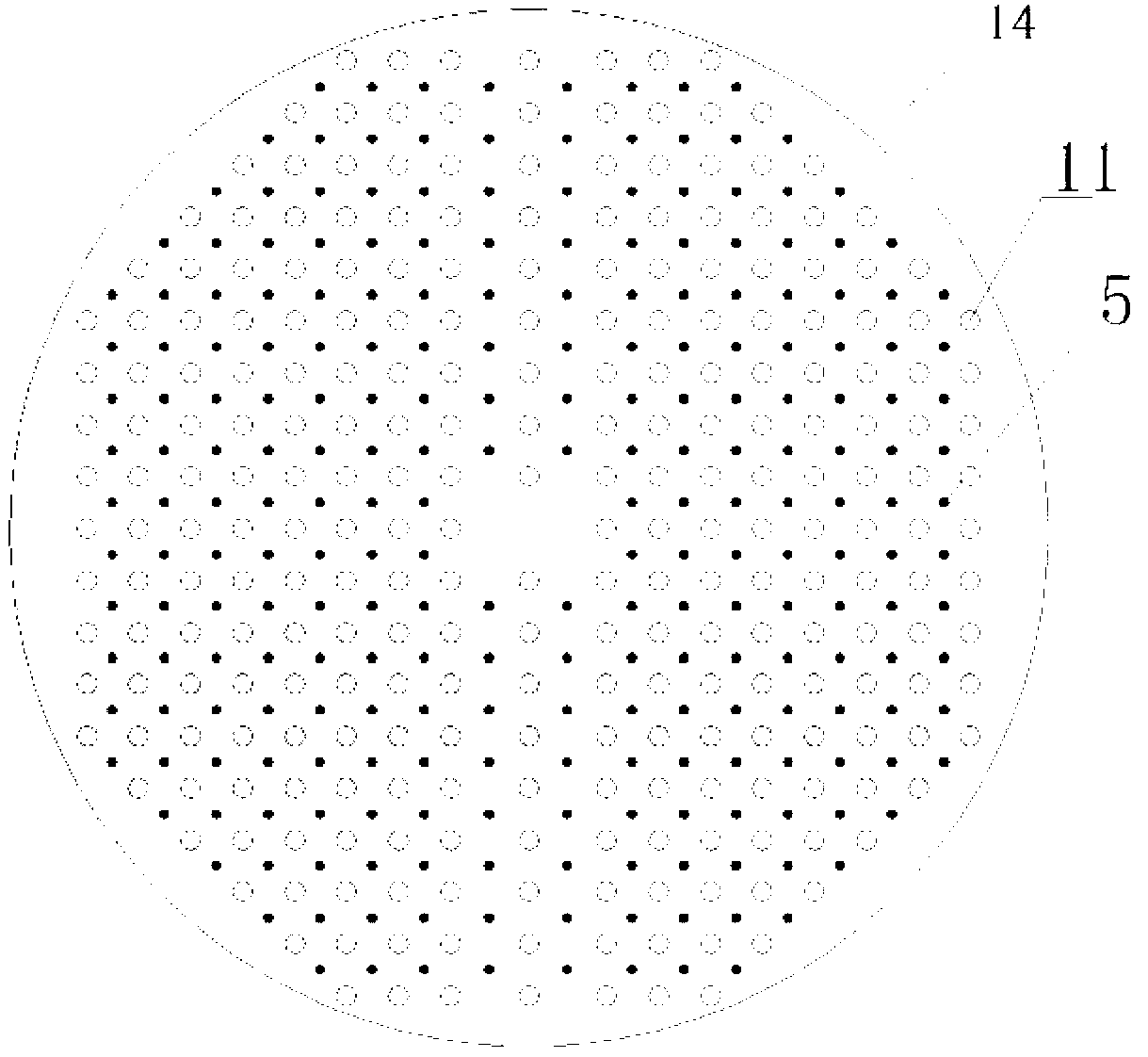

[0034] Such as figure 1 As shown, the output voltage of high-frequency power supply 1 is 0-15KV, and the output power is 200W. The matching network 2 is used to adjust the resistance-capacitance matching between the power supply and the electrode circuit load, to stabilize and control the discharge; the adjustable capacitance is 30pF, and the plate electrode 4 is Copper metal electrodes, needle electrodes 5 are copper electrodes with a cross-sectional diameter of 2mm, each capacitance connected to the needle electrodes 5 is 20pF, and the distance between the plate electrodes 4 and the needle electrodes 5 is 5mm. The activated carbon filling area 8 is filled with cylindrical granular activated carbon with a cross-sectional diameter of 2mm and a length of 3-5mm. The malodorous gas to be treated is methyl sulfide CH 3 SCH 3 , the initial concentration is 500mg / m 3 , The gas processing flow rate is 1L / min.

[0035] The malodorous gas methyl sulfide passes through the air inlet...

Embodiment 2

[0037] With embodiment 1, only the malodorous gas methyl sulfide processed in embodiment 1 is changed into ammonia, and its initial concentration is 200mg / m 3 , The gas treatment flow rate is 1L / min, the exhaust gas after treatment has no pungent smell, and the treatment efficiency of ammonia gas is above 96%.

Embodiment 3

[0039] Same as embodiment 1, only the malodorous gas methyl sulfide processed in embodiment 1 is changed into formaldehyde gas, and the initial concentration of formaldehyde is 600mg / m 3 , The gas treatment flow rate is 1L / min, the exhaust gas after treatment has no pungent smell, and the formaldehyde treatment efficiency is over 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com