Silver-iodide-doped bioactive glass as well as preparation method and application of silver-iodide-doped bioactive glass

A technology of bioactive glass and silver iodide, which is applied in the field of biomedicine and can solve the problems of lack of sterilization/bacteriostasis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

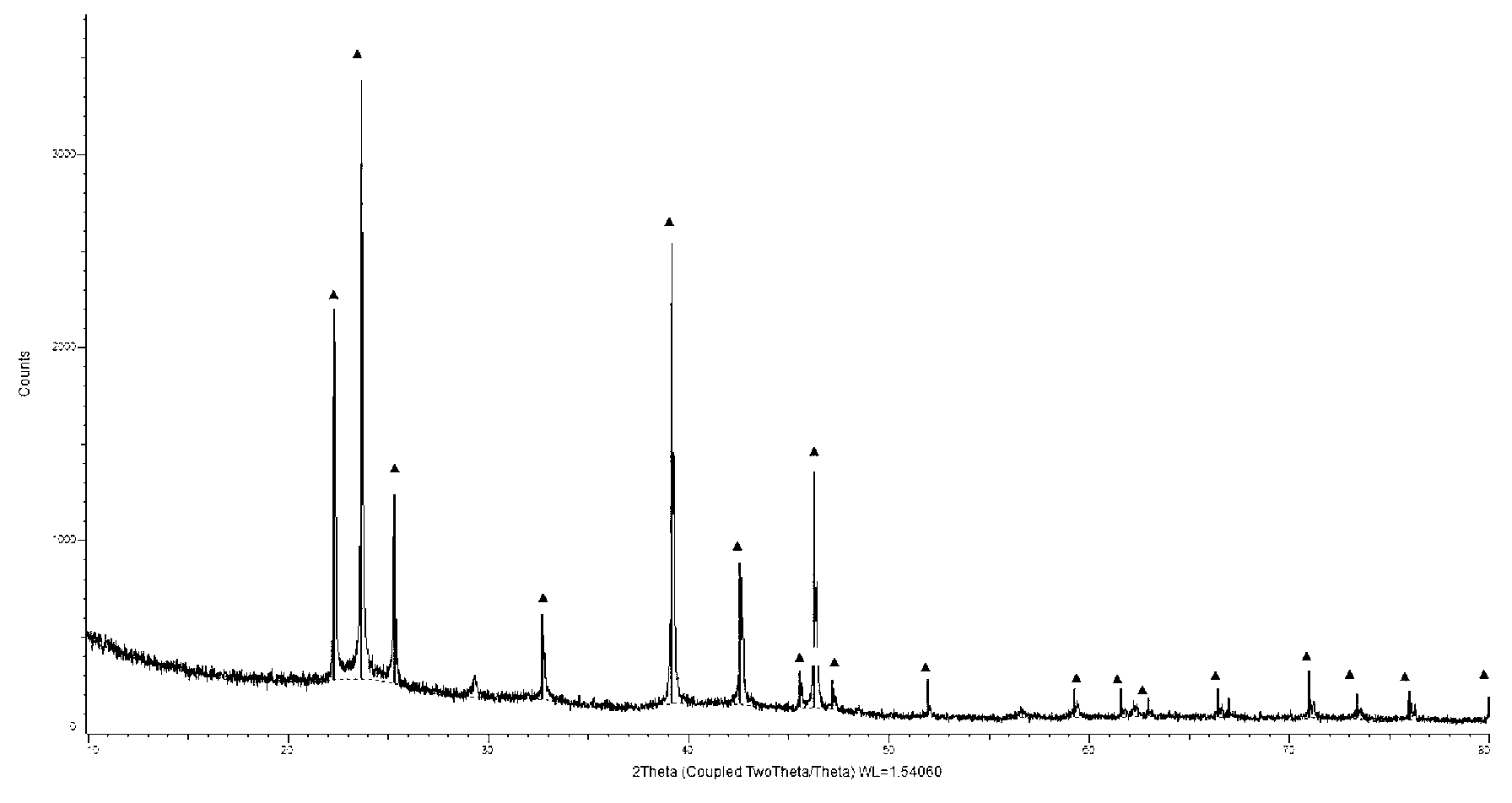

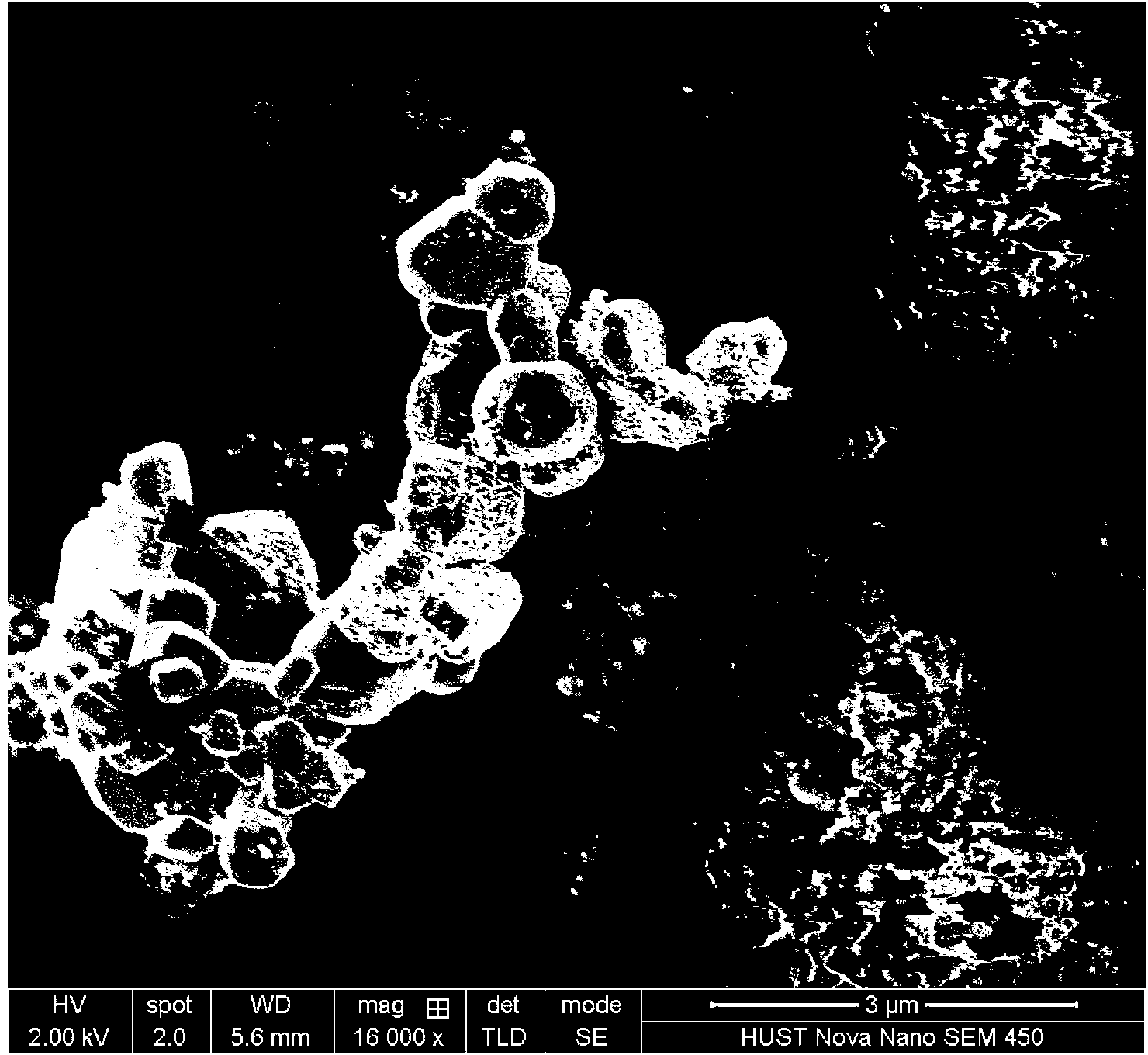

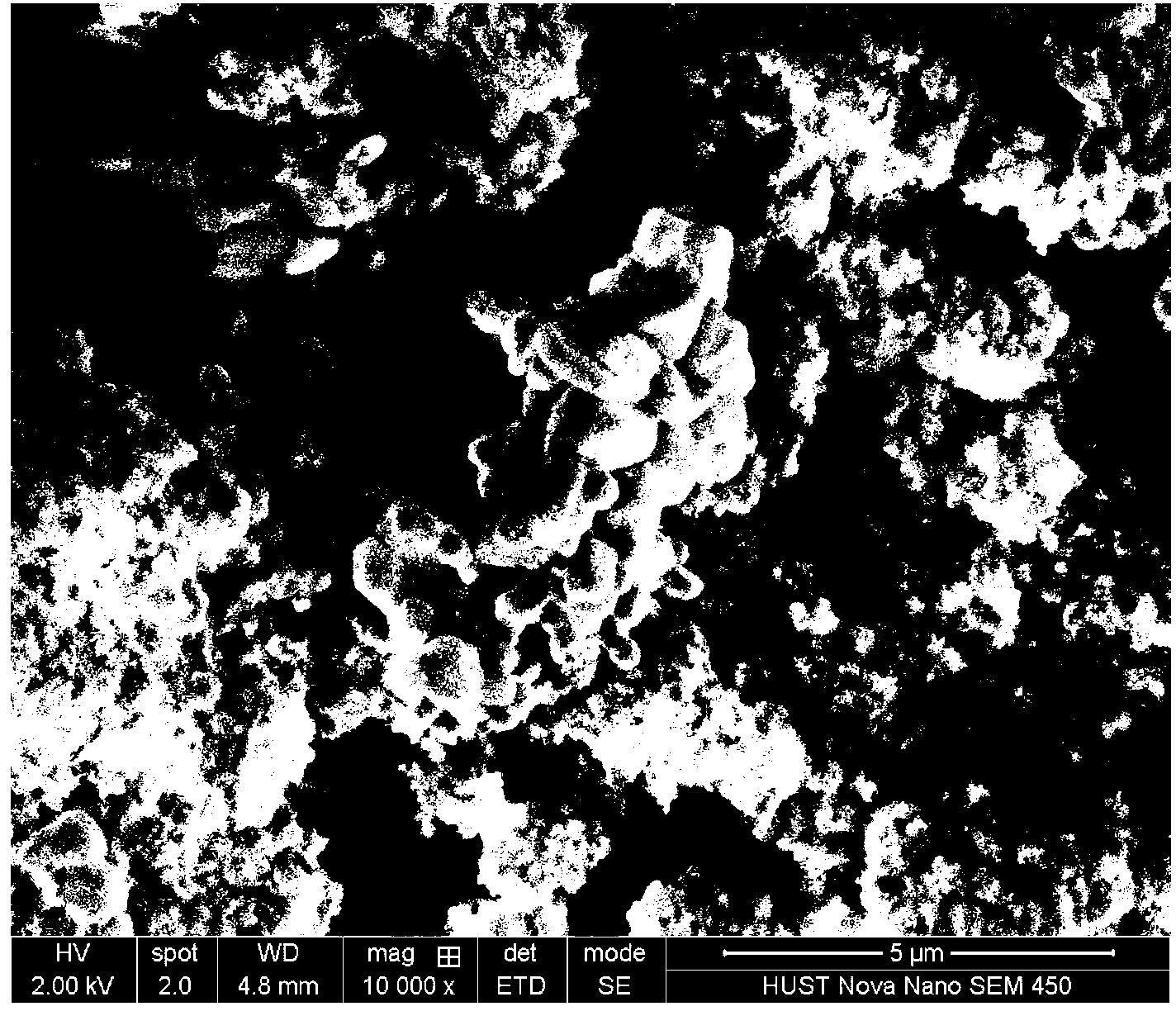

Image

Examples

preparation example Construction

[0053] Preparation of two kinds of bioactive glasses without silver iodide:

[0054] 1. Weigh SiO 2 9.5g, CaO4.0g, P 2 o 5 1.2g, Na 2 O3.0g, K 2 O0.8g, placed in a covered amber crucible, heated to 1350°C for 2h to melt and homogenize. Then it is poured into deionized water at 0° C. for quenching, the sintered material is hammered, ground, and passed through a 200-mesh sieve to obtain the non-silver iodide-doped bioactive glass.

[0055] 2. Weigh Ca(NO 3 ) 2 4H 2 O 15g, Na 2 O2.5g is added to appropriate amount of deionized water and ethanol, with NH 3 Adjust pH to 10~12 with water to obtain liquid C; take another 25ml of ethyl orthosilicate and 5ml of triethyl phosphate, add appropriate amount of absolute ethanol in turn, stir and dissolve to obtain liquid D; slowly add liquid C at 60°C In liquid D, put it in a magnetic stirrer and stir it at 300r / min for 5h, let it stand for aging for 72h, put it in a blast dryer at 105°C for 48h, and centrifuge to obtain a precipi...

Embodiment 1

[0057] Weigh 15g of non-silver iodide-doped bioactive glass, place it in 100ml of absolute ethanol, and stir it ultrasonically for 20min to make the mixture uniform, and obtain suspension A. Weigh 3.5 g of silver nitrate, add it into solution A, and stir ultrasonically for 10 minutes to obtain suspension B. Weigh 2.0 g of iodine and 2.5 g of potassium iodide and add them into solution B; in a water bath at 60°C, stir ultrasonically for 30 min, and then centrifuge. First wash the precipitate twice with an appropriate amount of deionized water, then wash twice with an appropriate amount of absolute ethanol, dry in a blast drying oven at 65°C for 36 hours, take it out, cool to room temperature, and then dry it in a freeze dryer for 48 hours to obtain Silver iodide-doped bioactive glass powder with a particle size of <50 μm (all the above raw materials are analytically pure).

Embodiment 2

[0059] Weigh 15g of bioactive glass and place it in 100ml of absolute ethanol, stir ultrasonically for 20min to make the mixture uniform, and obtain suspension A. Weigh 3.5 g of silver nitrate, add it into solution A, and stir ultrasonically for 10 minutes to obtain suspension B. Weigh 2.0 g of iodine and 2.5 g of potassium iodide and add them into solution B; in a water bath at 60°C, stir ultrasonically for 30 min, and then centrifuge. First wash the precipitate twice with an appropriate amount of deionized water, then wash it twice with an appropriate amount of absolute ethanol, dry it in a blast drying oven at 65°C for 36 hours, take it out and cool it to room temperature, and then dry it in a freeze dryer for 48 hours to obtain granules. Silver iodide-doped bioactive glass powder with a diameter of <50 μm (all the above raw materials are analytically pure).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com