Method for preparing inorganic scintillator film

A bulk film and inorganic technology, which is applied in the field of preparation of inorganic scintillator film, can solve the problems of slow thick film speed, long operation time, and high vacuum degree requirements, and achieve the effects of strong adhesion, low cost, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing an inorganic scintillator film layer, the specific preparation steps are as follows:

[0031] Step 1: Set the evaporation program of the substrate, raise the temperature from room temperature to 300 degrees in 100s, keep it at 300 degrees for 6400s, and then cool down naturally.

[0032] Step 2: Set the evaporation program of the evaporation source. First, the temperature is raised from room temperature to 300 degrees in 100s, and kept at 300 degrees for 300s, then raised to 350 degrees in 100s, kept in heat for 6000s, and then cooled down naturally.

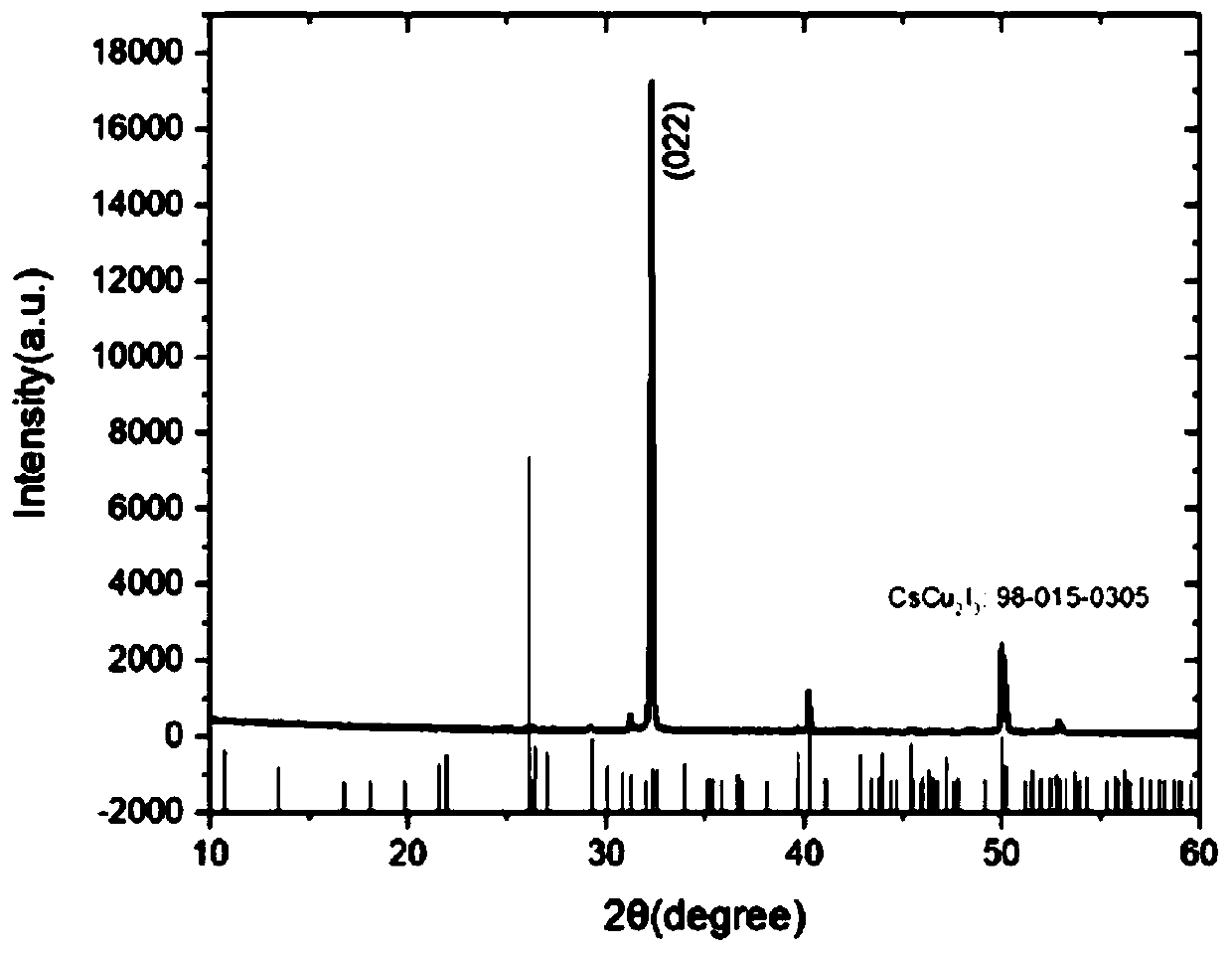

[0033] Step 3: Grinding the pure phase of CsCu 2 I 3 The powder was used as the evaporation source, and the cleaned FTO was used as the substrate, which were respectively placed in the deposition chamber of the near-space sublimation furnace, and the distance between the evaporation source and the substrate was adjusted to 1cm.

[0034] Step 4: Turn on the mechanical pump and pump the vacuum until...

Embodiment 2

[0037] This embodiment comprises the following steps:

[0038] Step 1: Set the evaporation program of the substrate, raise the temperature from room temperature to 300 degrees in 100s, keep it at 300 degrees for 6400s, and then cool down naturally.

[0039] Step 2: Set the evaporation program of the evaporation source. First, the temperature is raised from room temperature to 300 degrees in 100s, and kept at 300 degrees for 300s, then raised to 400 degrees in 100s, kept in heat for 6000s, and then cooled down naturally.

[0040] Step 3: Grinding the pure phase of CsCu 2 I 3 The powder was used as the evaporation source, and the cleaned FTO was used as the substrate, which were respectively placed in the deposition chamber of the near-space sublimation furnace, and the distance between the evaporation source and the substrate was adjusted to 0.5 cm.

[0041] Step 4: Turn on the mechanical pump and pump the vacuum until the vacuum degree in the deposition chamber is 4Pa.

[0...

Embodiment 3

[0044] This embodiment comprises the following steps:

[0045] Step 1: Set the evaporation program of the substrate, raise the temperature from room temperature to 300 degrees in 100s, keep it at 300 degrees for 6400s, and then cool down naturally.

[0046] Step 2: Set the evaporation program of the evaporation source. First, the temperature is raised from room temperature to 300 degrees in 100s, and kept at 300 degrees for 300s, then raised to 350 degrees in 100s, kept in heat for 6000s, and then cooled down naturally.

[0047] Step 3: Grinding the pure phase of CsCu 2 I 3 The powder was used as the evaporation source, and the cleaned FTO was used as the substrate, which were respectively placed in the deposition chamber of the near-space sublimation furnace, and the distance between the evaporation source and the substrate was adjusted to 1cm.

[0048] Step 4: Turn on the mechanical pump and pump the vacuum until the vacuum degree in the deposition chamber is 3Pa.

[0049...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com