Method for coating inner wall of electron-enhanced plasma discharge tube

A plasma and discharge tube technology, which is applied in the field of plasma discharge tube inner wall coating, can solve the problems of non-metallic tube inner wall coating, slow deposition speed, unsuitable for straight long thin tubes and special-shaped tubes, etc. Fast, simple equipment, high plasma density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

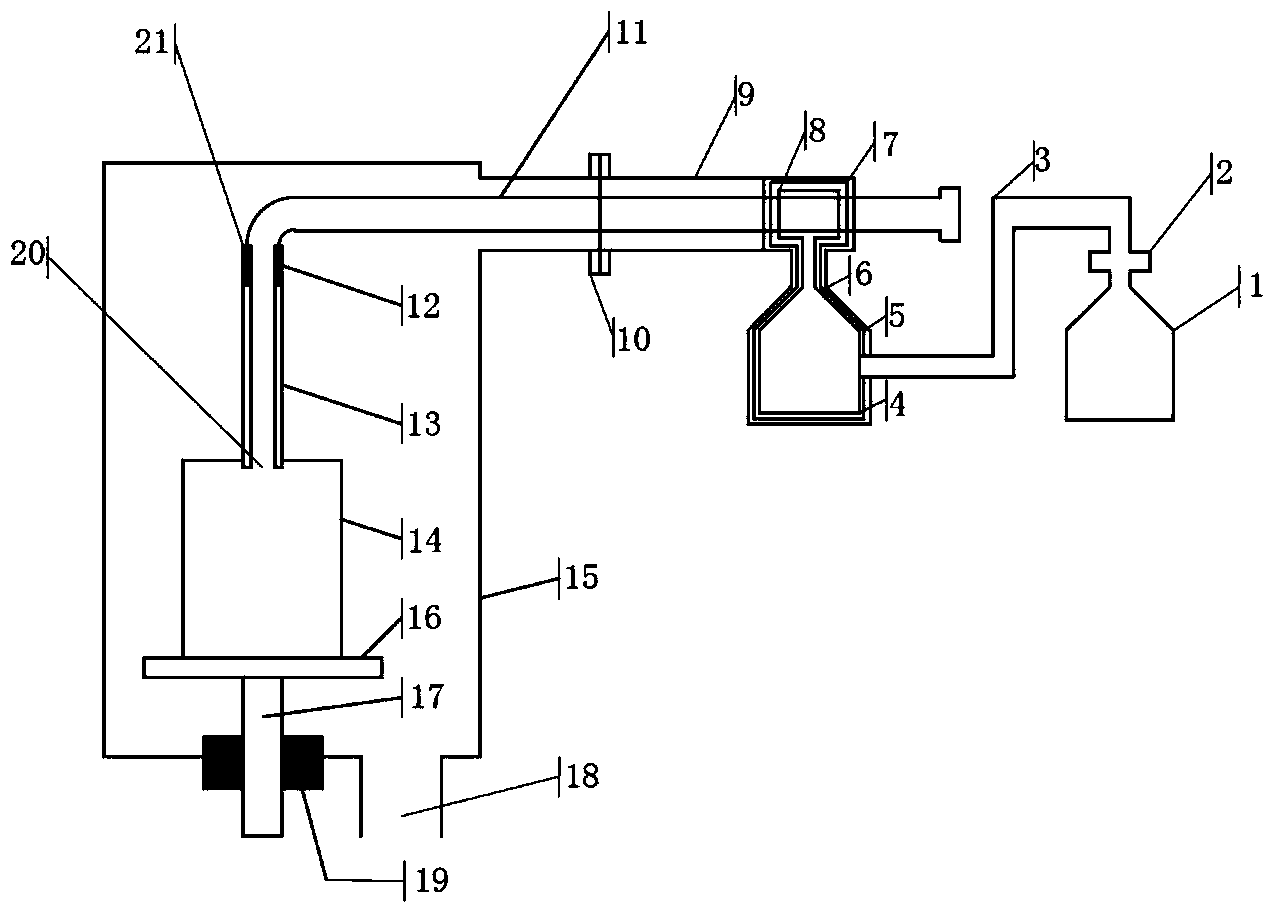

[0028] Embodiment 1: Taking the molybdenum coating on the inner wall of the pipe as an example, a straight pipe with an inner diameter of 4 mm and a length of 100 mm is selected as the pipe to be treated. The straight pipe is made of insulating material quartz. The insulating short tube is made of quartz. take figure 1 In the device, the specific steps of the method are as follows:

[0029] Step 1: cleaning the inner wall of the tube 13 to be treated before coating: ultrasonically clean the tube to be treated with absolute ethanol for 10 minutes, and then dry the inner wall of the tube with an air pump.

[0030] Step 2: the coating device is connected, one end of the tube 13 to be treated is connected to the insulating cover 14 with a hole in the center of the end face, the insulating cover 14 is placed on the cathode target platform 16 supported by the workbench support 17, and the insulating ceramic 19 is located on the workbench support Between the vacuum chamber and the...

Embodiment 2

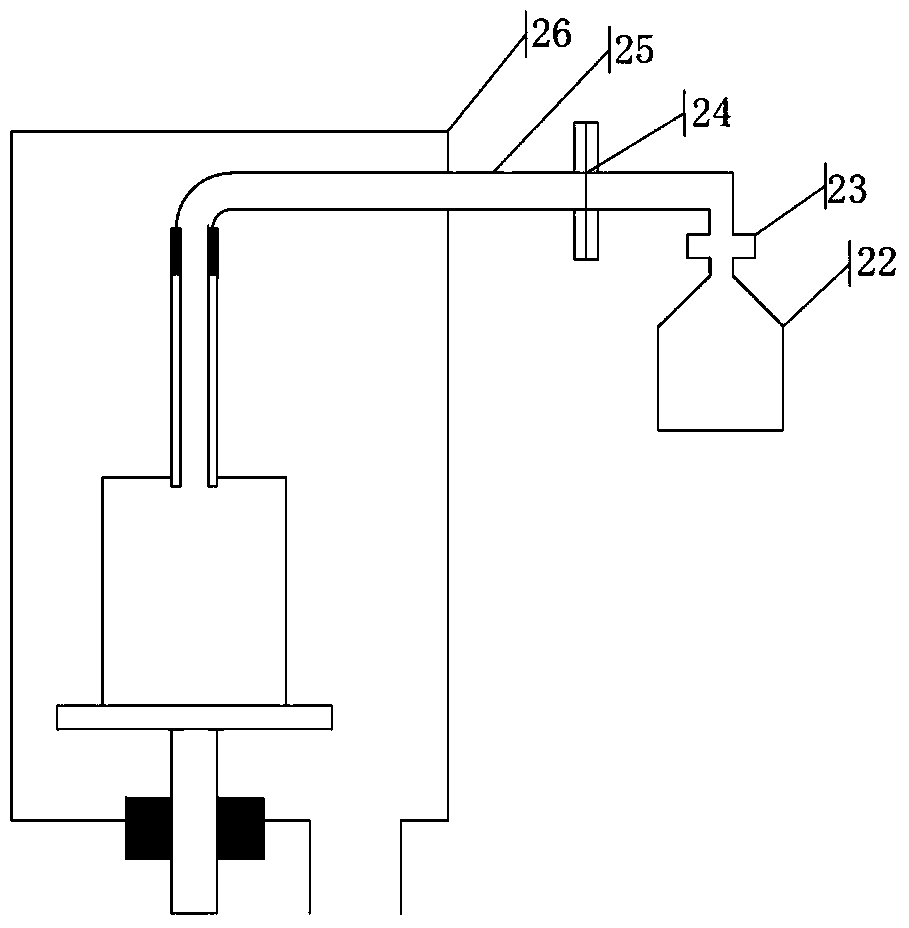

[0036] Embodiment 2: Taking the diamond-like carbon film (DLC) coating on the inner wall of the pipe as an example, a straight pipe with an inner diameter of 4mm and a length of 100mm is selected as the pipe to be treated. The straight pipe is made of insulating material quartz. The insulating short tube is made of quartz. take figure 2 device in figure 2 The vacuum chamber part of the device and figure 1 Consistent, the specific steps of the method are as follows:

[0037] Step 1: cleaning the inner wall of the tube 13 to be treated before coating: ultrasonically clean the tube to be treated with absolute ethanol for 10 minutes, and then dry the inner wall of the tube with an air pump.

[0038] Step 2: The coating device is connected, and the parts in the vacuum chamber are connected with the figure 1 The same as shown, the part outside the vacuum: the gas in the gas cylinder 22 passes into the vacuum chamber 26 through the particle feeding pipeline 25 , and the partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com