Energy-stored photovoltaic battery and manufacturing method thereof

A photovoltaic cell and energy storage technology, applied in the energy field, can solve the problems of limiting the miniaturization of solar cells and the difficulty of carrying external devices, and achieve good photoelectric conversion efficiency and power storage capacity, good power storage function, and reduced thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

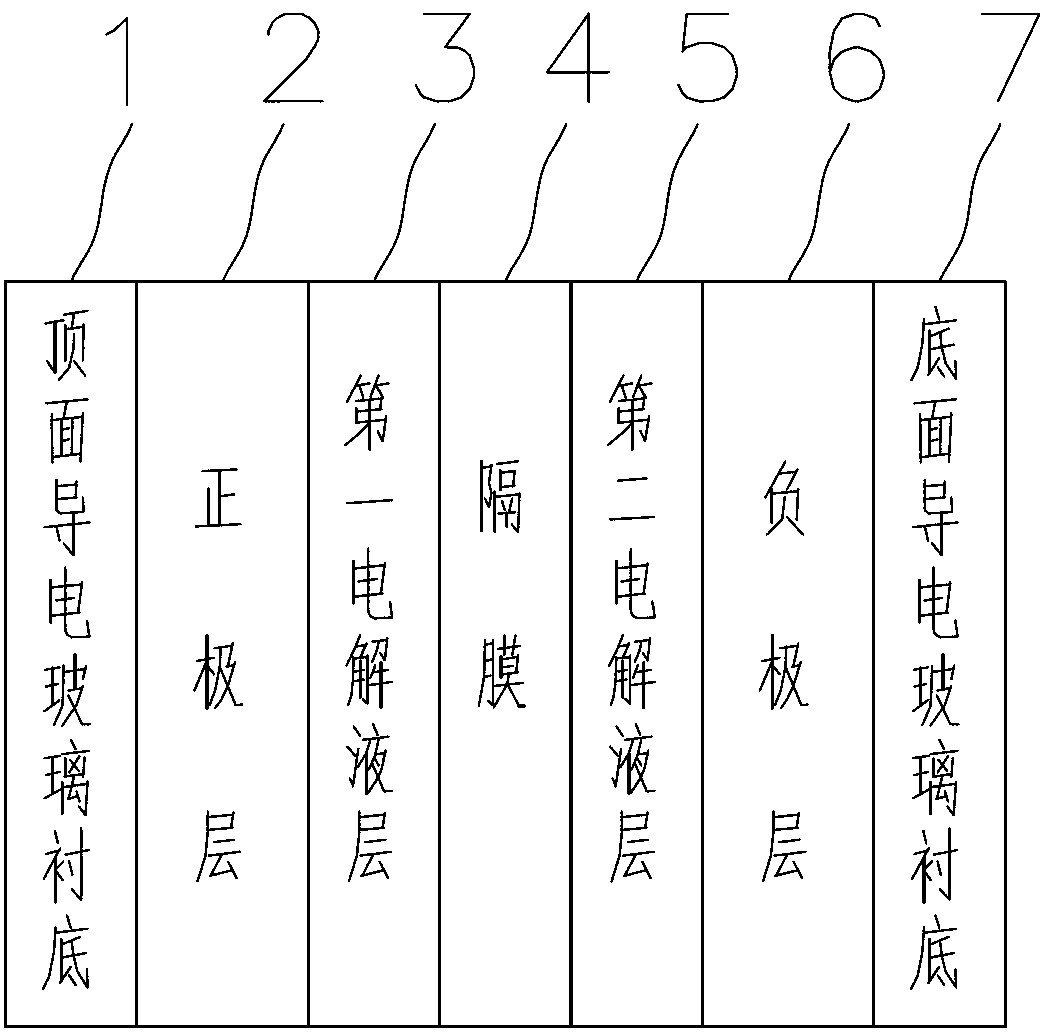

[0027] Add 10 mL of tetrabutyl titanate into a beaker, add 10 mL of absolute ethanol, add 5 mL of concentrated sulfuric acid under ice bath, stir to mix evenly to obtain a mixed solution, wait for the temperature of the mixed solution to drop to room temperature, and then add 10 mL of formaldehyde solution (mass fraction 35%), after waiting for 10min, add 10g of powdered resorcinol, 1g of succinic acid and 0.1g of hexadecyltrimethylammonium bromide, stir vigorously with a stirrer for 10 minutes, and place the mixture in vacuum drying at 150°C In the box for 2 hours, then take out the mixture, grind for 1 hour, and burn the obtained solid at 850°C for 6 hours under the condition of liquid seal to obtain uniform black carbon-rich TiO 2 ; To the uniform black carbon-rich TiO 2 Add 0.5 mL of 0.15 mol / L acetic acid solution and grind for 2 hours until it becomes viscous, apply it on the conductive surface of the top conductive glass substrate 1 at one time, and bake at 130°C for 0....

Embodiment 2

[0032] Add 10mL tetrabutyl titanate into a beaker, add 10mL absolute ethanol, add 5mL concentrated sulfuric acid under ice bath, stir to mix evenly to obtain a mixed solution, wait for the temperature of the mixed solution to drop to room temperature, then add 15mL formaldehyde solution (mass fraction 35%), after waiting for 10min, add 10g of powdered resorcinol, 1.5g of succinic acid and 0.1g of hexadecyltrimethylammonium bromide, stir vigorously with a stirrer for 10 minutes, and place the mixture in a vacuum at 150°C Dry the oven for 2 hours, then take out the mixture, grind for 1 hour, and burn the obtained solid at 850°C for 6 hours under the condition of liquid seal to obtain uniform black carbon-rich TiO 2 , to the uniform black carbon-rich TiO 2 Add 0.5 mL of 0.15 mol / L acetic acid solution and grind for 2 hours until it becomes viscous, apply it on the conductive surface of the top conductive glass substrate 1 at one time, and bake at 130°C for 0.5 hours on the surfac...

Embodiment 3

[0037] Add 10mL tetrabutyl titanate into a beaker, add 10mL absolute ethanol, add 5mL concentrated sulfuric acid under ice bath, stir to mix evenly to obtain a mixed solution, wait for the temperature of the mixed solution to drop to room temperature, then add 20mL aqueous formaldehyde (mass fraction 35%), after waiting for 10min, add 10g of powdered resorcinol, 2g of succinic acid and 0.1g of hexadecyltrimethylammonium bromide, stir vigorously with a stirrer for 10 minutes, and place the mixture in a 150°C vacuum-dried In the box for 2 hours, then take out the mixture, grind for 1 hour, and burn the obtained solid at 850°C for 6 hours under the condition of liquid seal to obtain uniform black carbon-rich TiO 2 , to the uniform black carbon-rich TiO 2 Add 0.5 mL of N-methylpyrrolidone and grind for 2 hours until viscous, apply it on the conductive surface of the top conductive glass substrate 1 at one time, bake at 130°C for 0.5 hours on the conductive surface of the top condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com