Diffusion and brightness enhancement film and method for manufacturing same

A manufacturing method and diffusion membrane technology, applied in the direction of chemical instruments and methods, instruments, layered products, etc., can solve the problems of poor thermal stability, absorption, folding, etc., to reduce the number of membranes used, reduce manufacturing costs, and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] According to the following ingredients by weight percentage: PET88%, polyethylene 6%, ethylene-ethyl methacrylate-glycidyl methacrylate triblock copolymer 6%;

[0074] Put the ingredients into the twin-screw extruder, melt at 275°C, vacuum pump, pass through the melt filter, metering pump, melt pipe and die to form a melt film, the die temperature is 280°C, the melt film Cool the surface of the chilled roll at 35°C to form a thick film;

[0075] The film is preheated at 95°C, stretched longitudinally at 100°C, the stretching ratio is 3 times, and cooled at 25°C to obtain a unidirectional longitudinally stretched film;

[0076] The film is preheated at 100°C, stretched transversely at 120°C, the stretching ratio is 3.5 times, heat-set at 230°C, and relax 6% in the width direction;

[0077] On one surface of the light-diffusing film, a photosensitive composition (82% high-refractive-index acrylic acid, 12% 2-phenylethyl methacrylate, 3% acrylate-1,6-hexanediol, and photo...

Embodiment 2

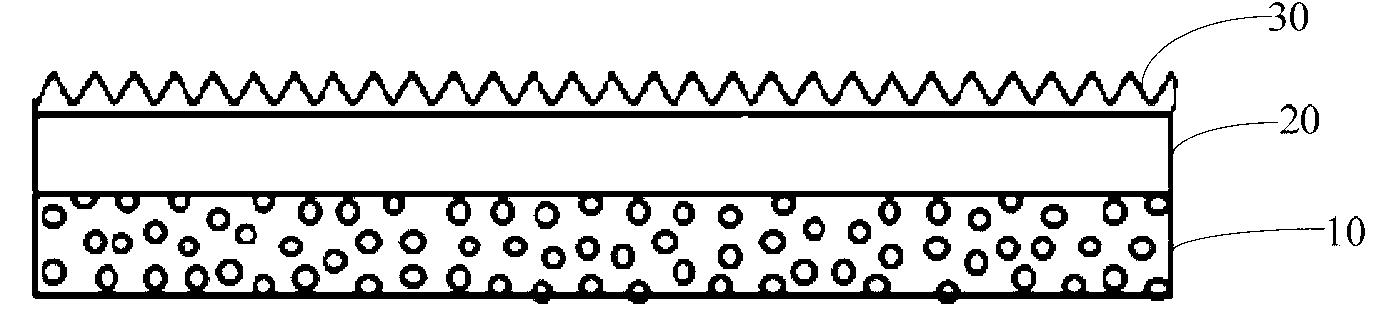

[0079] The raw materials of the diffusion layer are configured according to the following weight percentages: PET79%, colloidal silicon dioxide 10%, ethylene-ethyl methacrylate-glycidyl methacrylate triblock copolymer 6%, polyethylene 5%; support layer Raw material: PET100%. The manufacturing method is the same as that of Example 1, and the structure of the diffused brightening film can be found in figure 2 or image 3 .

Embodiment 3

[0081] Diffusion layer raw materials are configured according to the following weight percentages: PET90%, silicon dioxide 7%, acrylic particles 3%; supporting layer raw materials: PET100%. The manufacturing method is the same as that of Example 1, and the structure of the diffused brightening film can be found in Figure 4 or Figure 5 .

[0082] The diffusion brightening film provided by the invention and its manufacturing method adopt processes such as blending, melt extrusion, casting, biaxial stretching, heat setting, cooling, etc., and the diffusion particles are uniformly dispersed in the base resin to prepare a thermally stable film. For a good diffusion film, the diffusion film passes through a light curing molding machine to solidify and form a microstructure on the surface.

[0083]The present invention effectively integrates the existing mature molding process, combines the diffusion film and the brightness enhancement film together for manufacture, does not use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com