Self-rolling adhesive film

A film-bonding and winding technology, applied in the direction of bonding method, pressure-sensitive film/sheet, film/sheet release liner, etc., can solve the problems of easy deformation, difficult to recycle, etc., to prevent damage and improve productivity , the effect of reducing peel stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0150] (Example of adhesive production)

[0151] Adhesive 1

[0152]Acrylic polymer is obtained by copolymerization of ethyl acetate solution with 0.2 weight part of polymerization initiator 2,2'-azobisisobutyronitrile added to 100 weight parts of a mixture of butyl acrylate:acrylic acid=100:3 (weight ratio). material (weight average molecular weight 1.1 million).

[0153] With respect to 100 parts by weight of the obtained acrylic polymer, 2 parts by weight of an isocyanate compound (manufactured by Nippon Polyurethane Industry Co., Ltd., trade name CORONATE L) and 0.4 parts by weight of an epoxy compound (manufactured by Mitsubishi Gas Chemical Co., Ltd., trade name TETRAD-C) were added. parts by weight to obtain adhesive 1.

[0154] Adhesive 2

[0155] Acrylic polymer is obtained by copolymerization of ethyl acetate solution with 0.2 parts by weight of polymerization initiator benzoyl peroxide added in 100 parts by weight of 2-ethylhexyl acrylate:acrylic acid=100:5 (weig...

manufacture example

[0182] As the rigid film, a polyethylene terephthalate (PET) film (manufactured by Toray Industries, Inc., corona-treated on one side, LUMIRRORS105 (thickness 38 μm)) was used.

[0183] NB300 (manufactured by Dainichi Seika Co., Ltd. with light blue pigment added) was coated on the corona-treated surface side of the rigid film layer with a gravure coater so that the film thickness after drying was 1 to 2 μm, and dried to obtain Rigid film with organic coating.

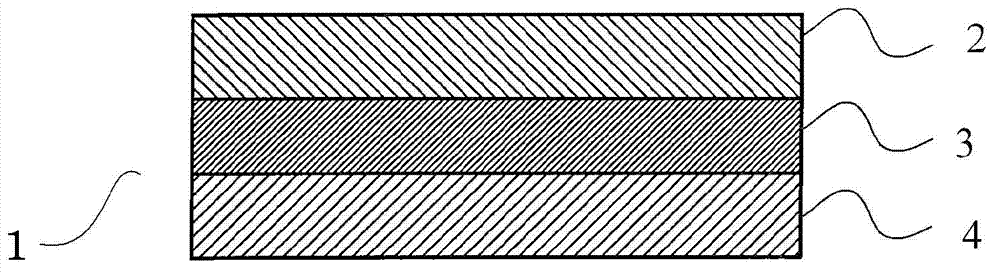

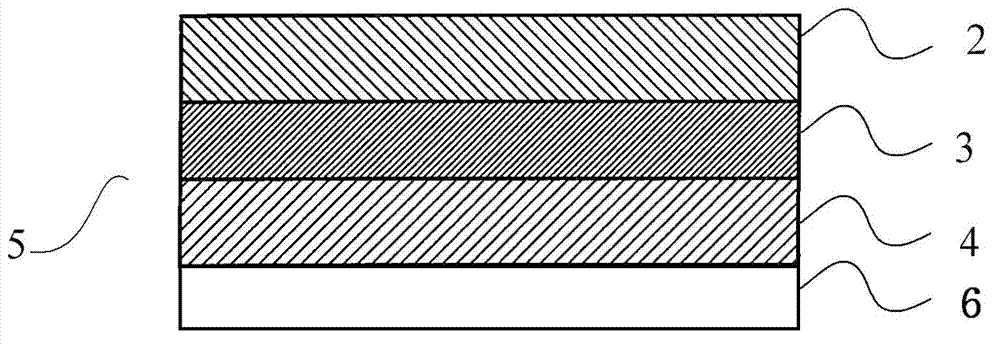

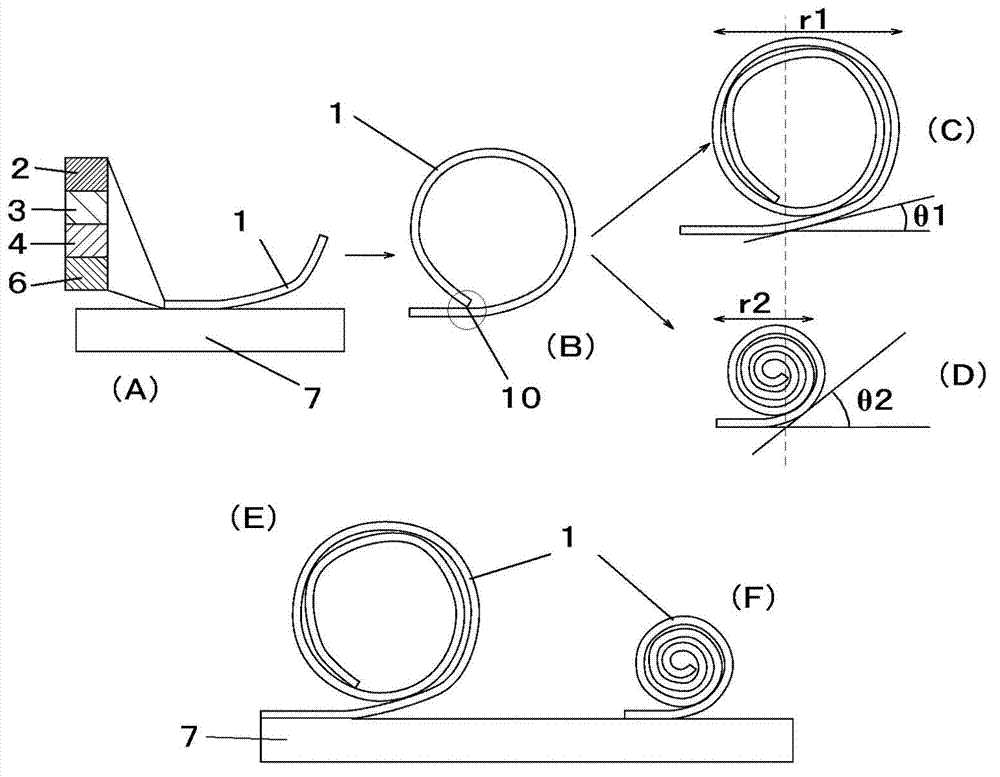

[0184] The opposite side of the organic coating layer of the aforementioned rigid film layer was bonded with a heat-shrinkable polyester film (manufactured by Toyobo Co., Ltd., SPACECLEAN S7200, film thickness 30 μm, corona-treated on one side) using an adhesive by dry lamination. Treatment) corona treatment surface bonding, the production of self-winding film substrate.

[0185] Among these, the adhesive used for dry lamination used what mixed the Mitsui Chemicals company Takelac A520, Takenate A10, and ethyl acetate...

Embodiment 1

[0188] Adhesive 1 was coated on the silicone-treated surface of PET that had been treated with release silicone using a die coater so that the film thickness after drying was 40 μm, and then attached to the spontaneous winding obtained in the production example. The organic coating side of the film for a self-winding adhesive film was obtained to obtain a self-winding adhesive film 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com