Method and device for pretreating raw materials of low-temperature water-soluble creep feed

A water-soluble education and pretreatment technology, applied in feed, food science, application, etc., can solve the problems of high temperature intolerance, low digestion and absorption rate, poor palatability, etc., and achieve convenient processing, high degree of automation, and improved digestion and absorption rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

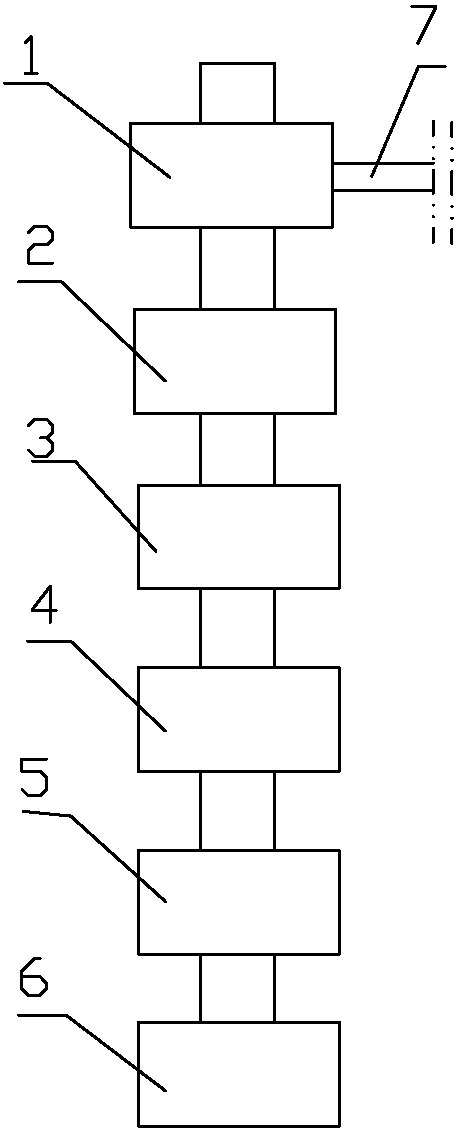

[0016] refer to figure 1 The present invention was made. The raw material pretreatment method of this low temperature water-soluble teaching tank material is characterized in that: it comprises the following steps to make:

[0017] (1) Conditioning and tempering of raw materials: the raw materials are sent to the feed conditioner, and steam is introduced to make the steam and the raw material powder evenly mixed; if required, additional fats, sugars and other liquids can be added to the conditioner. add;

[0018] (2) Expansion and dehydration: When the quenched and tempered material enters the expander, the temperature is 90~100℃, and the moisture content is 17%~21%. Friction, the magnitude of the force can be controlled by adjusting the annular gap of the discharge port through the hydraulic system, so that the discharge temperature reaches 100 ~ 110 ℃, and the residence time of the material in the expander is 3 ~ 7 seconds. When the vessel passes through the annular gap o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com