Method for comprehensively utilizing euphausia superba shells

An Antarctic krill and astaxanthin technology, applied in the application, fish protein composition, food science and other directions, can solve the problems of non-recycling of protein, low quality of chitin products, large amount of acid and alkali, etc. The effect of realizing sustainable economic development, promoting technological transformation and technological level, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

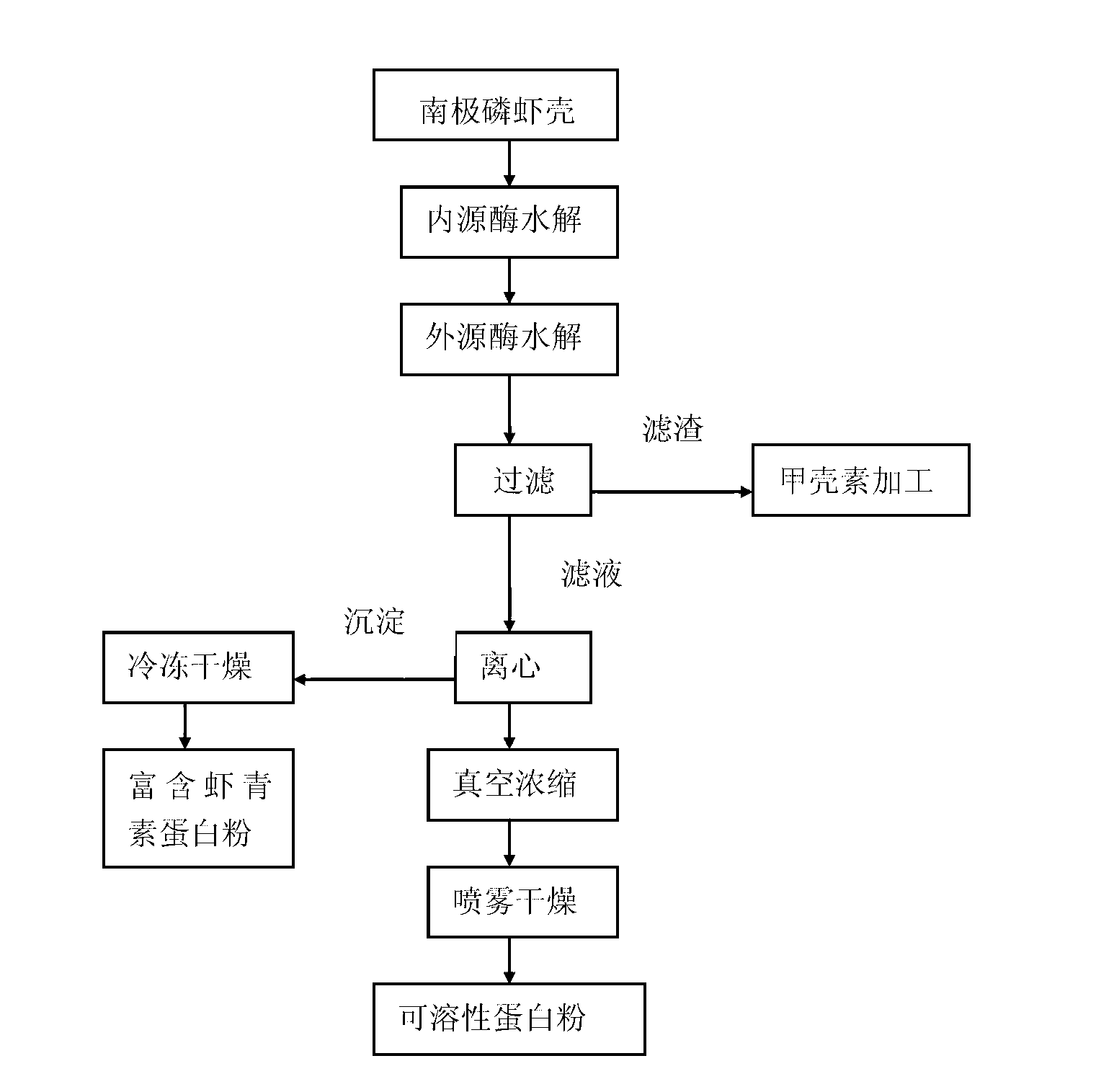

Image

Examples

Embodiment 1

[0016] The raw material is frozen Antarctic krill shells. The shrimp shells are added to water according to the shrimp shell / water mass ratio of 1:4, heated to 50°C, kept warm, and stirred in the dark for 2 hours. Adjust the pH to 8.0, add alkaline protease for enzymolysis, the dosage is 3000U / g protein according to the enzyme activity, and stir for 1.5h in the dark, and filter with a 60-mesh filter after the reaction. The filtrate was centrifuged at 4000rpm for 15min, and the supernatant was separated from the precipitate. The supernatant was concentrated in vacuum until the soluble solids were 35% and then spray-dried to obtain protein powder with a protein content of 85%. The centrifuged precipitate was freeze-dried to obtain protein powder rich in astaxanthin, wherein the protein content was 50%, and the astaxanthin content was 900mg / kg. The remaining residue after filtration is used to prepare chitin.

Embodiment 2

[0018] Frozen Antarctic krill shells are used as raw materials, and the Antarctic krill shells are added to water at a mass ratio of Antarctic krill shells / water of 1:6, heated to 60°C, kept warm, and stirred for 1.5 hours in the dark. Adjust the pH to 8.0, add alkaline protease for enzymolysis, the dosage is 1500U / g protein according to the enzyme activity, keep away from light and stir for 2.5h, filter with a 60-mesh filter after the reaction, and centrifuge the enzymolysis solution at 5000rpm After 15 min, the supernatant was separated from the precipitate. The supernatant was concentrated in vacuum until the soluble solids were 32% and then spray-dried to obtain protein powder with a protein content of 82%. The centrifugal precipitate was freeze-dried to obtain protein powder rich in astaxanthin, wherein the protein content was 55%, and the astaxanthin content was 750mg / kg. The remaining residue after filtration is used to prepare chitin.

Embodiment 3

[0020] The raw material is frozen Antarctic krill processing scraps, and the scraps are added to water according to the ratio of scraps / water mass of 1:5, heated to 55°C, kept warm, and stirred for 1 hour in the dark. Adjust the pH to 8.5, add alkaline protease for enzymolysis, the dosage is 2000U / g protein according to the enzyme activity, and stir for 2 hours in the dark, and filter with a 60-mesh filter after the reaction. The filtrate was centrifuged at 3000 rpm for 15 min, and the supernatant was separated from the precipitate. The supernatant was concentrated in vacuum until the soluble solids were 30% and then spray-dried to obtain protein powder with a protein content of 75%. The centrifugal precipitate was freeze-dried to obtain protein powder rich in astaxanthin, wherein the protein content was 60%, and the astaxanthin content was 600 mg / kg. Other operations are the same as in Example 1. The remaining residue after filtration is used to prepare chitin.

[0021] Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com