Array substrate, display device and manufacturing method of array substrate

An array substrate and manufacturing method technology, applied in the display field, can solve the problems of low panel aperture ratio and transmittance, achieve the effects of increasing aperture ratio and transmittance, reducing storage capacitance, and reducing charging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

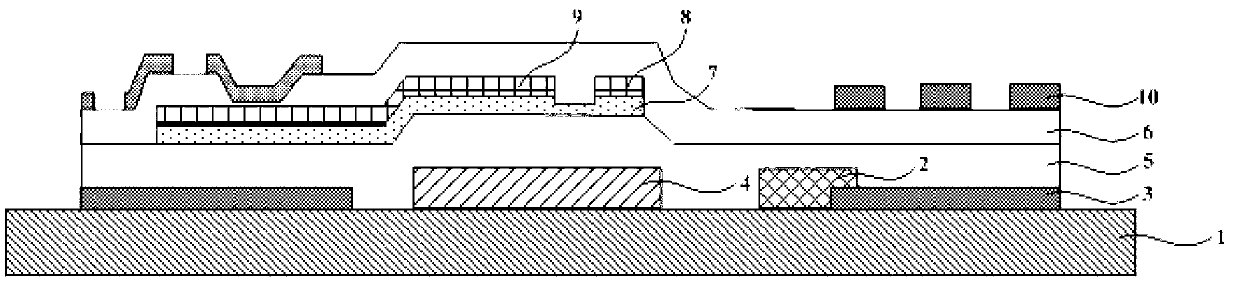

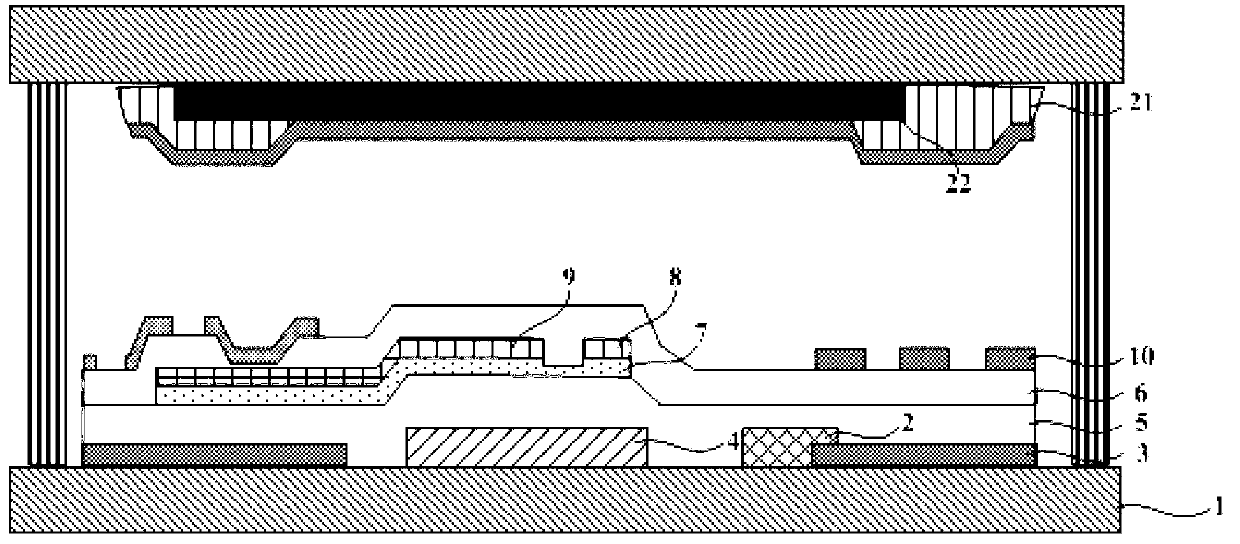

[0044] In order to increase the panel aperture ratio, the present invention provides an array substrate, a display device and a manufacturing method of the array substrate. In this technical solution, since the common electrode lines are located below the scanning lines, the line width of the black matrix on the color filter substrate can be reduced correspondingly, thereby improving the panel aperture ratio and transmittance, and between the scanning lines and the common electrode lines. The electrode lines are separated by an insulating layer, which effectively reduces the storage capacitance, thereby shortening the charging time of the pixel. In order to make the purpose, technical solution and advantages of the present invention clearer, the following specific examples are given to further describe the present invention in detail.

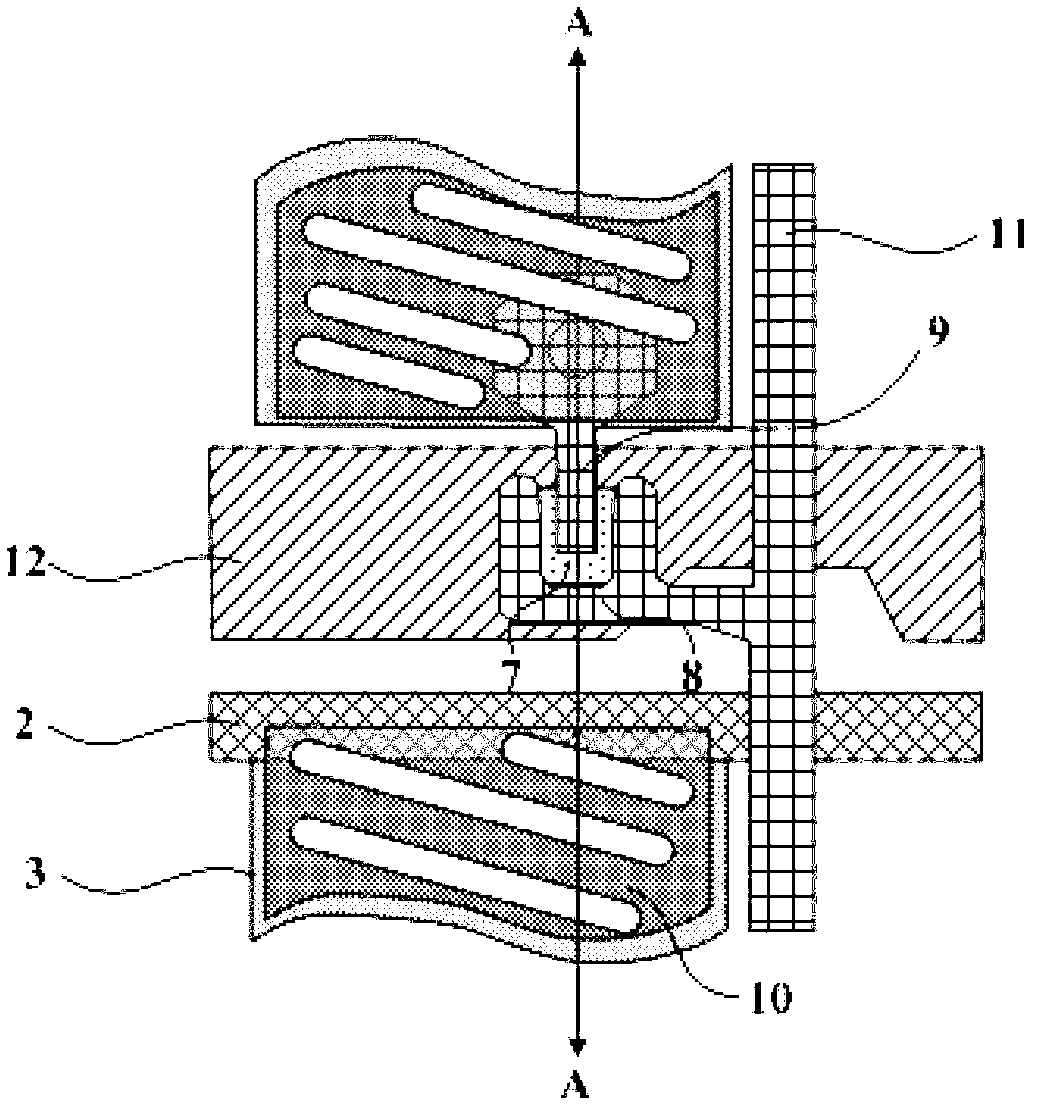

[0045] Such as Figure 4 As shown, a schematic structural diagram of an embodiment of the array substrate of the present invention, Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com