Backlight module and membrane positioning structure thereof

A positioning structure and backlight module technology, applied in the direction of light source fixing, optical, electric light source, etc., can solve the problems of diaphragm jumping, warping, diaphragm wrinkles, etc., to prevent jumping, improve production capacity and product yield , to ensure the effect of optical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be understood that the specific embodiments described herein are only used to explain the present invention, and not to limit the present invention.

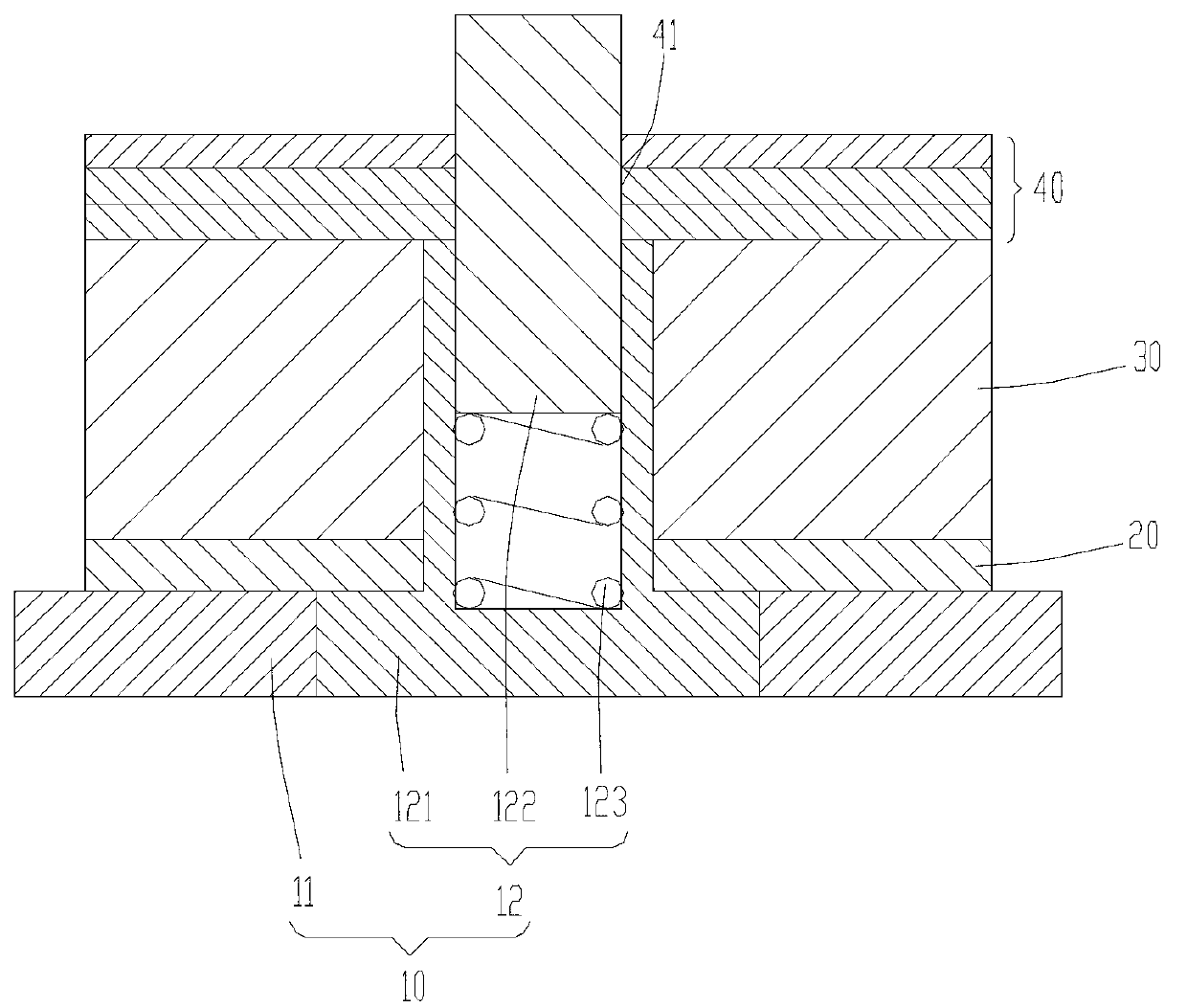

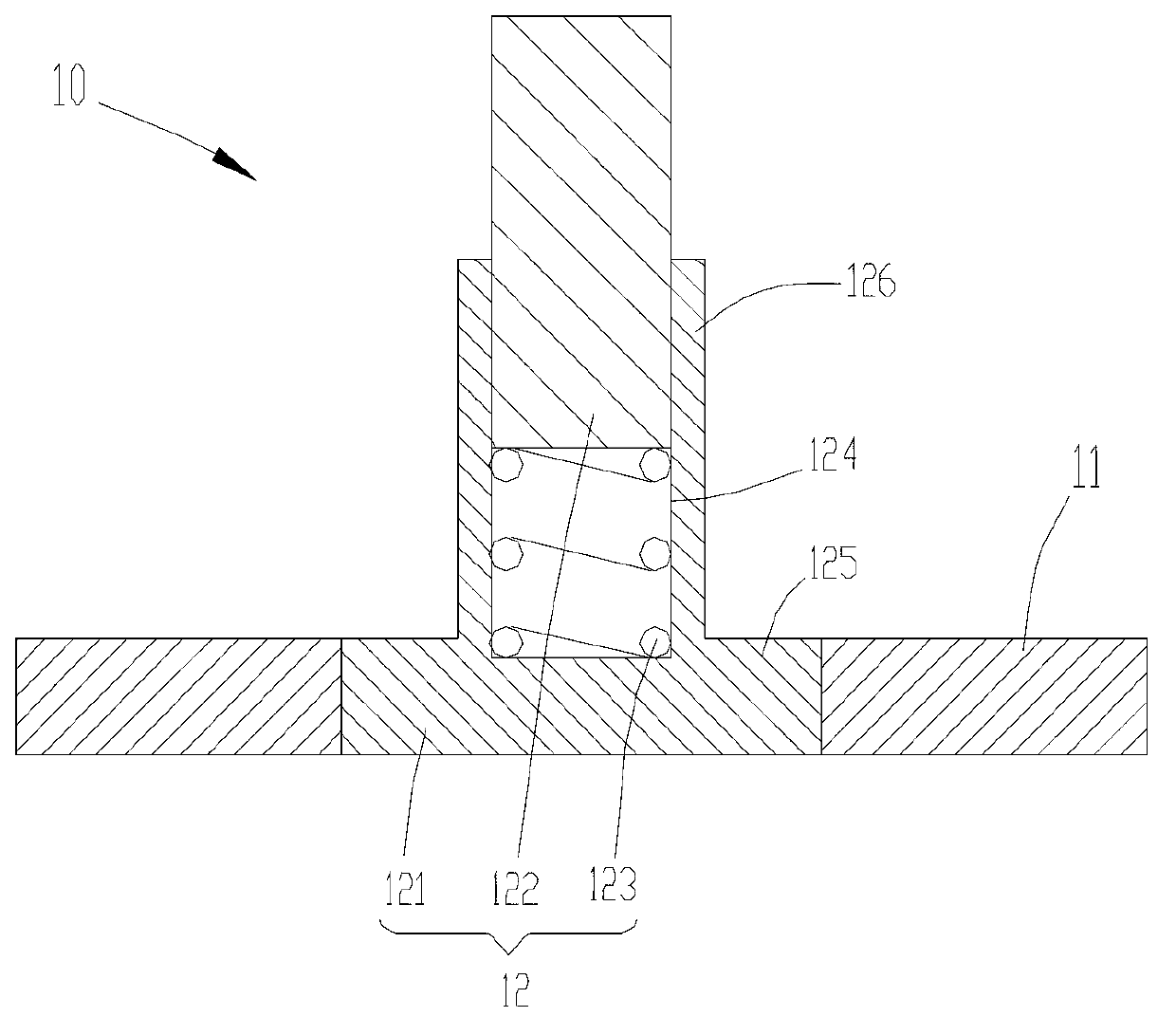

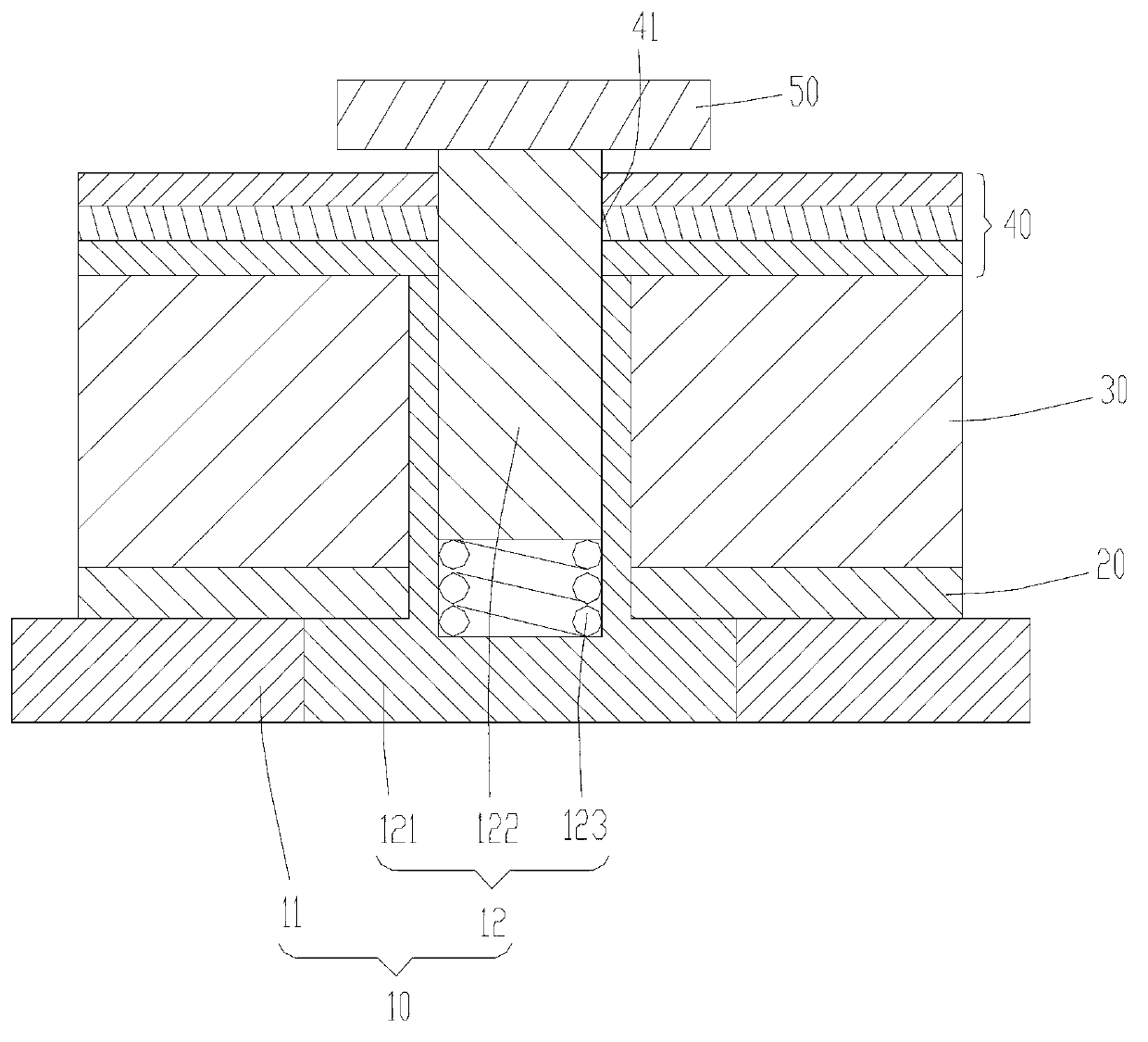

[0021] Such as Figure 1 to Figure 3 What is shown is a preferred embodiment of the backlight module of the present invention.

[0022] The backlight module includes a diaphragm positioning structure 10, a reflective sheet 20, a light guide plate 30 and a diaphragm 40.

[0023] The diaphragm positioning structure 10 includes a back plate 11 and a positioning member 12. The positioning member 12 includes a base 121, a positioning column 122 and an elastic body 123. The base 121 is fixedly connected with the back plate 11, the base 121 is provided with a guide hole 124, the elastic body 123 and the positioning post 122 are sequentially arranged in the guide hole 124, and the elastic body 123 is sandwiched between the bottom surface of the guide hole 124 and the positioning post 122 . The elastic body 123 is an element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com