A kind of manufacturing method of nylon functional air-cleaning negative ion air-covered yarn

An air-coated yarn and air-cleaning technology is applied in the spinning field to improve production efficiency, odor and smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

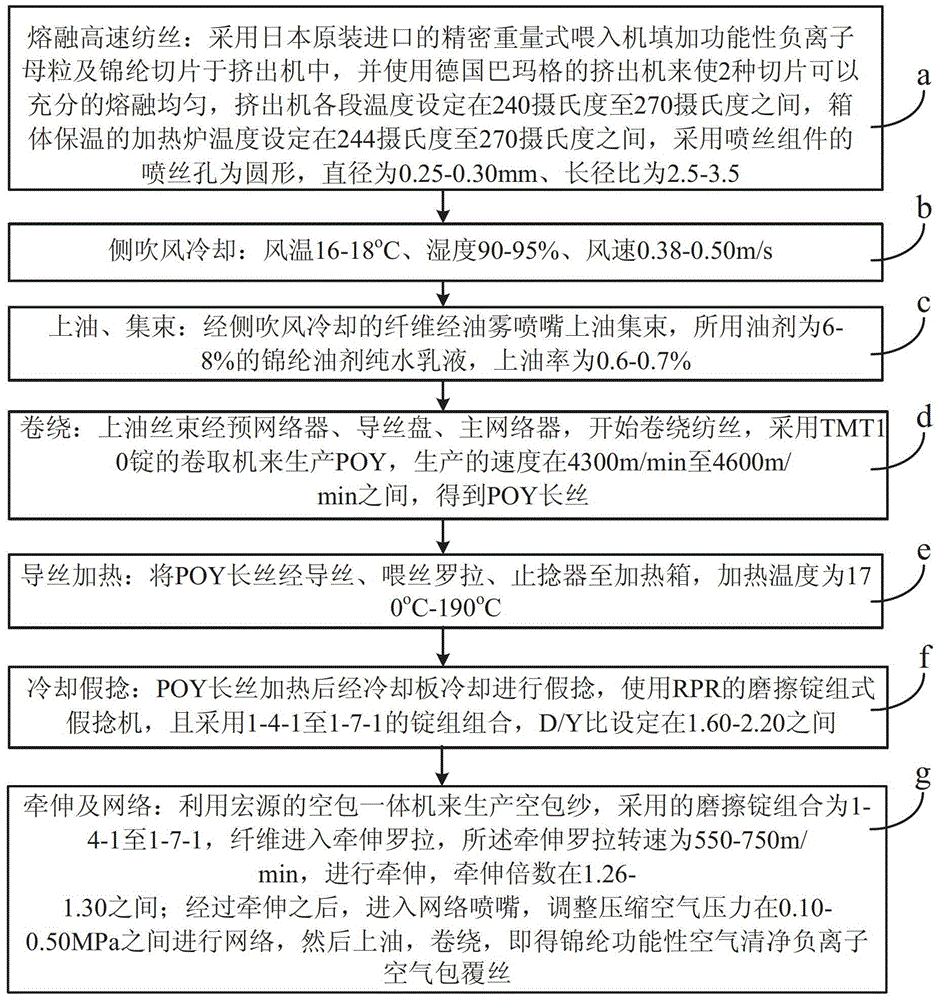

[0038] A kind of manufacture method of nylon functional air clean negative ion air covering silk, comprises the following steps:

[0039] a) Melt high-speed spinning: The precision weight feeding machine imported from Japan is used to add functional anion masterbatch and nylon chips into the extruder. The content of functional anion masterbatch is 6%, and the German Bama The standard extruder is used to make the two kinds of slices fully melt and evenly. The temperature of each section of the extruder is set at 240°C, 250°C, 253°C, 255°C, and 256°C. The temperature of the heating furnace for box insulation is set at 262°C, the spinneret hole of the spinneret assembly is circular, with a diameter of 0.25mm, an aspect ratio of 2.5, and the number of spinneret holes is 34;

[0040] b) Cooling by side blowing: wind temperature 16°C, humidity 90%, wind speed 0.38m / s.

[0041] c) Oiling and clustering: the fibers cooled by side blowing are oiled and clustered through the oil mist n...

Embodiment 2

[0048] A kind of manufacture method of nylon functional air clean negative ion air covering silk, comprises the following steps:

[0049] a) Melt high-speed spinning: The precision weight feeding machine imported from Japan is used to add functional anion masterbatch and nylon chips into the extruder. The content of functional anion masterbatch is 7%, and the German Bama The standard extruder is used to make the two kinds of slices fully melt and uniform. The temperature of each section of the extruder is set at 240°C, 250°C, 253°C, 255°C, and 270°C. The temperature of the heating furnace for box insulation is set at 244°C, the spinneret hole of the spinneret assembly is circular, with a diameter of 0.24mm, an aspect ratio of 2.5, and the number of spinneret holes is 48;

[0050] b) Cooling by side blowing: wind temperature 18°C, humidity 95%, wind speed 0.45m / s;

[0051] c) Oiling and clustering: the fibers cooled by side blowing are oiled and clustered through the oil mist ...

Embodiment 3

[0058] A kind of manufacture method of nylon functional air clean negative ion air covering silk, comprises the following steps:

[0059] a) Melt high-speed spinning: The precision gravimetric feeding machine imported from Japan is used to add functional anion masterbatch and nylon chips into the extruder. The content of functional anion masterbatch is 8%, and German Bama is used. The standard extruder is used to make the two kinds of slices fully melt and evenly. The temperature of each section of the extruder is set at 240°C, 251°C, 252°C, 260°C, and 268°C. The temperature of the heating furnace for box insulation is set at 268°C, the spinneret hole of the spinneret assembly is circular, with a diameter of 0.22mm, an aspect ratio of 2.5, and the number of spinneret holes is 68;

[0060] b) Side blowing cooling: wind temperature 17°C, humidity 92%, wind speed 0.50m / s;

[0061] c) Oiling and clustering: the fibers cooled by side blowing are oiled and clustered through the oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com