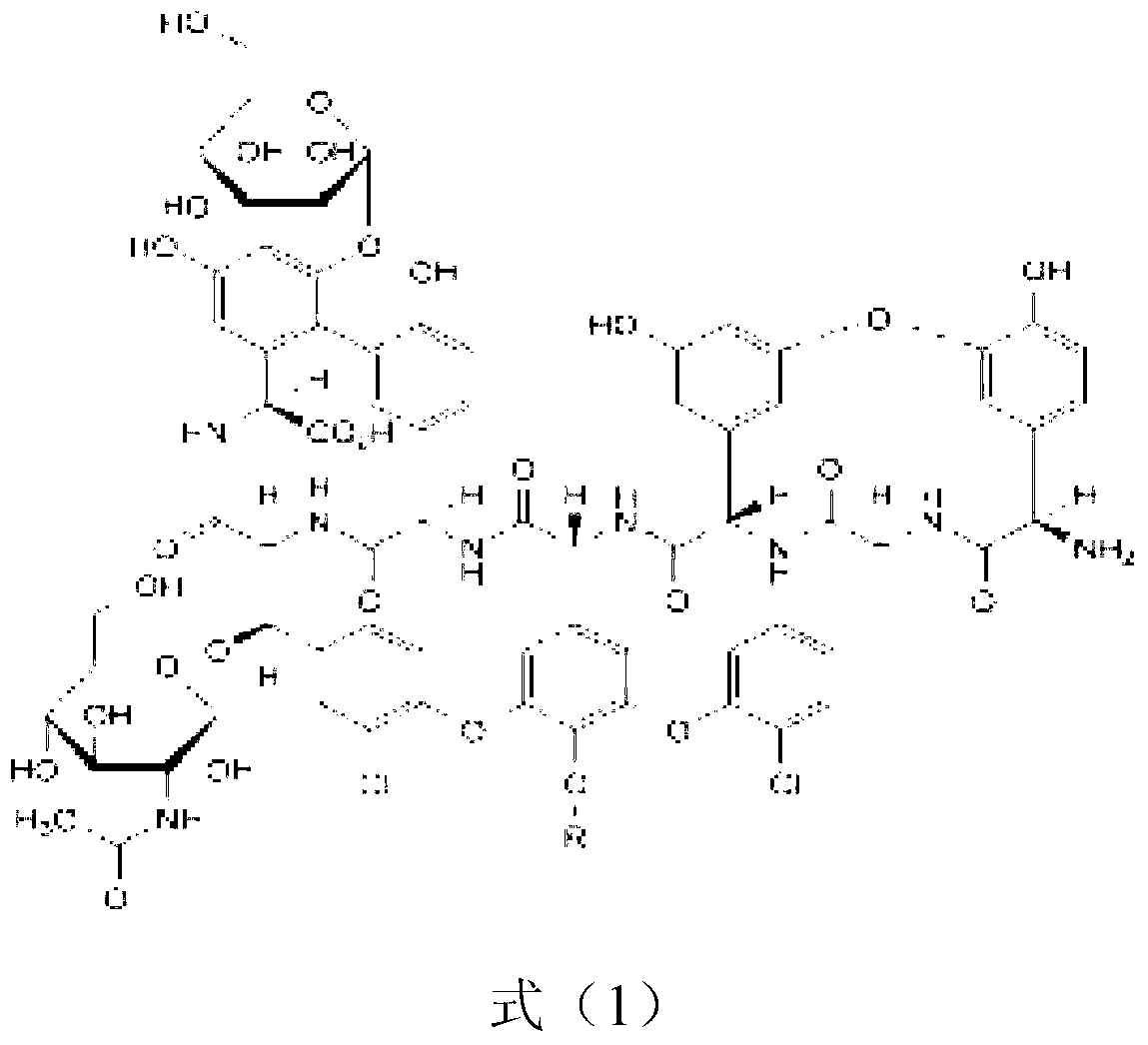

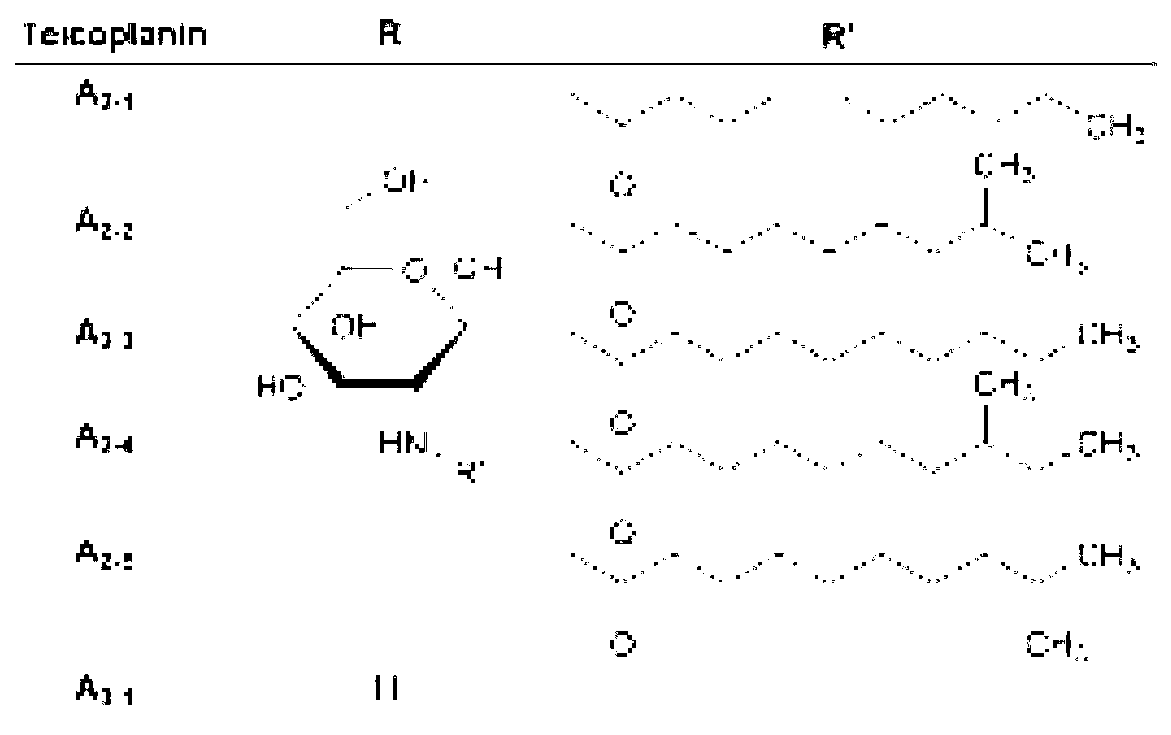

Separation and purification method of high-purity teicoplanin

A technology for separation and purification of teicoplanin, which is applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of difficult large-scale promotion, high production cost of nano-polymer microspheres, and unsuitability for industrial production, etc. problem, to achieve the effect of simple and easy method, stable yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of High Purity Teicoplanin

[0025] a, take 60 grams of teicoplanin crude product, the mass percentage is 75.6%, dissolve with purified water until the concentration of teicoplanin is 5000ug / ml, adjust the pH to 7, and pass into the chromatogram filled with 3L aluminum oxide The column is used for sample loading adsorption, wherein the particle size of aluminum oxide is 200-300 mesh, and the flow rate of sample loading is 0.3BV / h, until the concentration of teicoplanin in the effluent is greater than 100u / ml; then use 1BV / h Wash with water until the effluent is colorless, then wash with methanol at a volume ratio concentration of 5%, and wash with alcohol at a flow rate of 1BV / h until the effluent reaches 3BV; then wash with water at a rate of 1BV / h until the effluent It is colorless, and then eluted with a methanol aqueous solution with a volume ratio concentration of 40%, and the elution flow rate is 0.3BV / h, and the A in the elution effluent is determined...

Embodiment 2

[0032] a, take 60 grams of teicoplanin crude product, the mass percentage is 75.6%, dissolve with purified water until the concentration of teicoplanin is 20000ug / ml, adjust the pH to 9, pass into the chromatogram filled with 3L aluminum oxide The column is used for sample loading adsorption, wherein the particle size of aluminum oxide is 200-300 mesh, and the sample loading flow rate is 0.6BV / h, until the concentration of teicoplanin in the effluent is greater than 100u / ml; Wash with water until the effluent is colorless, then use an ethanol solution with a concentration of 30% by volume for alcohol washing, the flow rate of alcohol washing is 2BV / h, until the effluent reaches 4BV; then wash with water at a rate of 2BV / h until the effluent It is colorless, and then eluted with an ethanol aqueous solution with a volume ratio concentration of 90%, and the elution flow rate is 0.6BV / h, and the A in the elution effluent is determined. 2 Group components and impurity concentration...

Embodiment 3

[0039] a, take 60 grams of crude product of teicoplanin, the mass percentage is 75.6%, dissolve it with purified water until the concentration of teicoplanin is 10000ug / ml, adjust the pH to 7.5, and pass it into the chromatogram filled with 3L aluminum oxide The column is used for sample loading adsorption, wherein the particle size of aluminum oxide is 200-300 mesh, and the sample loading flow rate is 0.5BV / h, until the concentration of teicoplanin in the effluent is greater than 100u / ml; Wash with water at the rate until the effluent is colorless, then use isopropanol aqueous solution with a volume ratio concentration of 15% for alcohol washing, the flow rate of alcohol washing is 1.5BV / h, until the effluent reaches 3.5BV; then use 1.5BV / h Wash with water at a rate of 0.5BV / h until the effluent is colorless, then elute with isopropanol aqueous solution with a concentration of 70% by volume, and measure A in the eluted effluent. 2 Group components and impurity concentrations,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com