Method for producing active carbon by pyrolysing pepper branches

A technology for the production of activated carbon and activated carbon, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems that have not been reported, achieve good control effect, large output, and realize the effect of harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

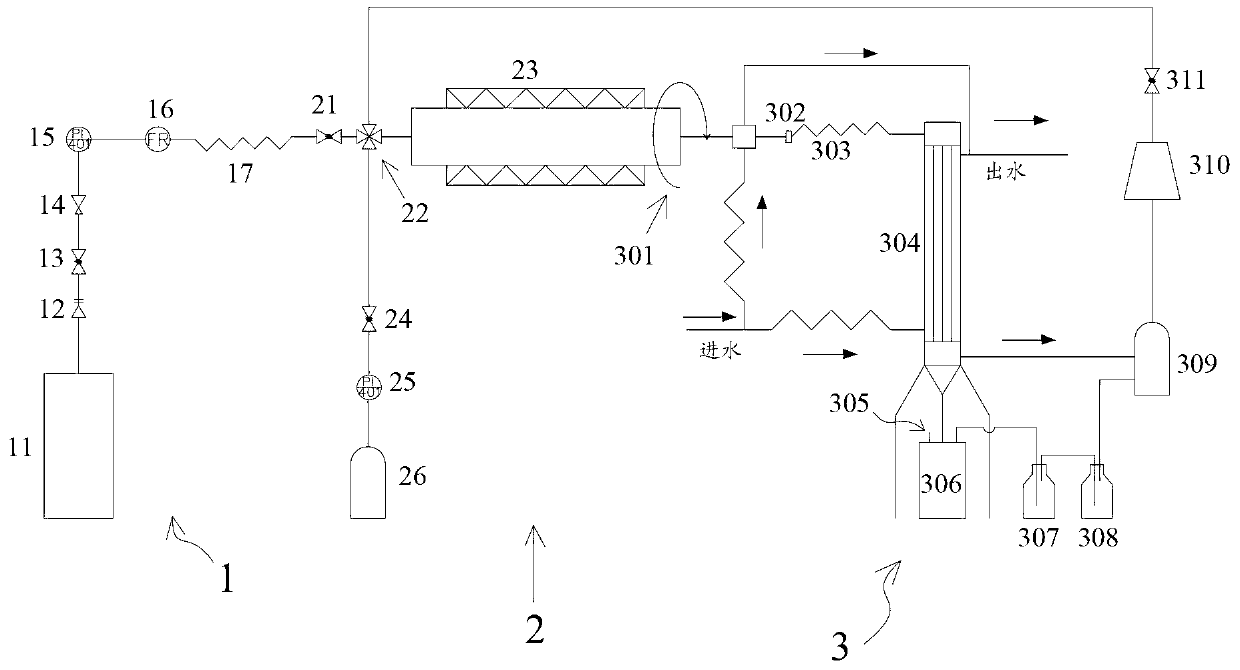

Image

Examples

Embodiment 1

[0036] Drying: Remove impurities from pruned Zanthoxylum bungeanum, then air-dry or dry at 105±5°C.

[0037] Crushing: Break the dried Zanthoxylum bungeanum branches into craft wooden strips with a length of 5-10cm.

[0038] Charcoal activation reaction: put the obtained craft sticks into the rotary kiln, set the temperature rise rate of the rotary kiln to 1°C / min, the charcoal activation temperature to 400°C, the charcoal activation time to 4h, the rotary kiln speed to 0.5rpm, start After heating up, feed water vapor and keep the flow rate of water vapor at 1kg / h, so that the pore structure of the raw material will gradually develop, and finally become activated carbon.

[0039] Pulverization: After the activated material is cooled, the tilting angle of the rotary furnace is adjusted to 14°, and the activated carbon is taken out from the rotary furnace tube and pulverized to ensure that the particle size of the product activated carbon meets the specified requirements.

[00...

Embodiment 2

[0044] Drying: Remove impurities from pruned Zanthoxylum bungeanum, then air-dry or dry at 105±5°C.

[0045] Crushing: Break the dried Zanthoxylum bungeanum branches into craft wooden strips with a length of 5-10cm.

[0046] Charcoal activation reaction: put the obtained craft sticks into the rotary kiln, set the temperature rise rate of the rotary kiln to 10°C / min, the charcoal activation temperature to 700°C, the charcoal activation time to 3h, and the rotary kiln speed to 1.5rpm, start After the temperature rises, water vapor is introduced to keep the flow of water vapor at 10kg / h, so that the pore structure of the raw material is gradually developed, and finally becomes activated carbon.

[0047] Pulverization: After the activated material is cooled, the tilting angle of the rotary furnace is adjusted to 14°, and the activated carbon is taken out from the rotary furnace tube and pulverized to ensure that the particle size of the product activated carbon meets the specified...

Embodiment 3

[0052] Drying: Remove impurities from pruned Zanthoxylum bungeanum, then air-dry or dry at 105±5°C.

[0053] Crushing: Break the dried Zanthoxylum bungeanum branches into craft wooden strips with a length of 5-10cm.

[0054] Charcoal activation reaction: put the obtained craft sticks into the rotary kiln, set the temperature rise rate of the rotary kiln to 10°C / min, the charcoal activation temperature to 800°C, the charcoal activation time to 2.5h, and the rotary kiln speed to 1.5rpm, After starting to heat up, feed water vapor and keep the flow rate of water vapor at 20kg / h, so that the pore structure of the raw material will gradually develop, and finally become activated carbon.

[0055] Pulverization: After the activated material is cooled, the tilting angle of the rotary furnace is adjusted to 14°, and the activated carbon is taken out from the rotary furnace tube and pulverized to ensure that the particle size of the product activated carbon meets the specified requireme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com