Bismuth-free stainless steel flux cored wire gas shielded welding technology for connecting pipes

A technology of gas shielded welding and flux-cored welding wire, which is used in manufacturing tools, welding equipment, arc welding equipment, etc. Influence and shorten the effect of product duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

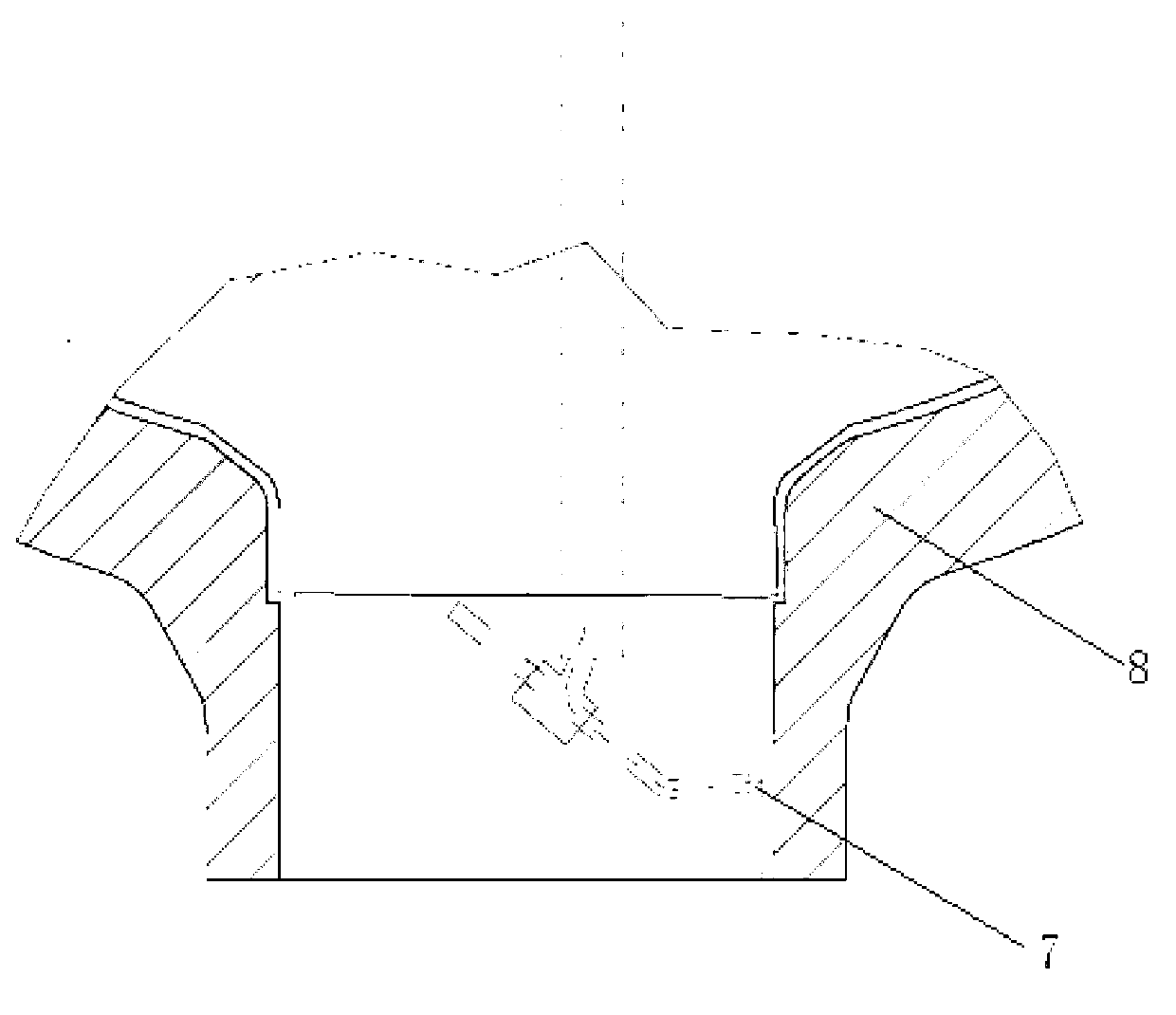

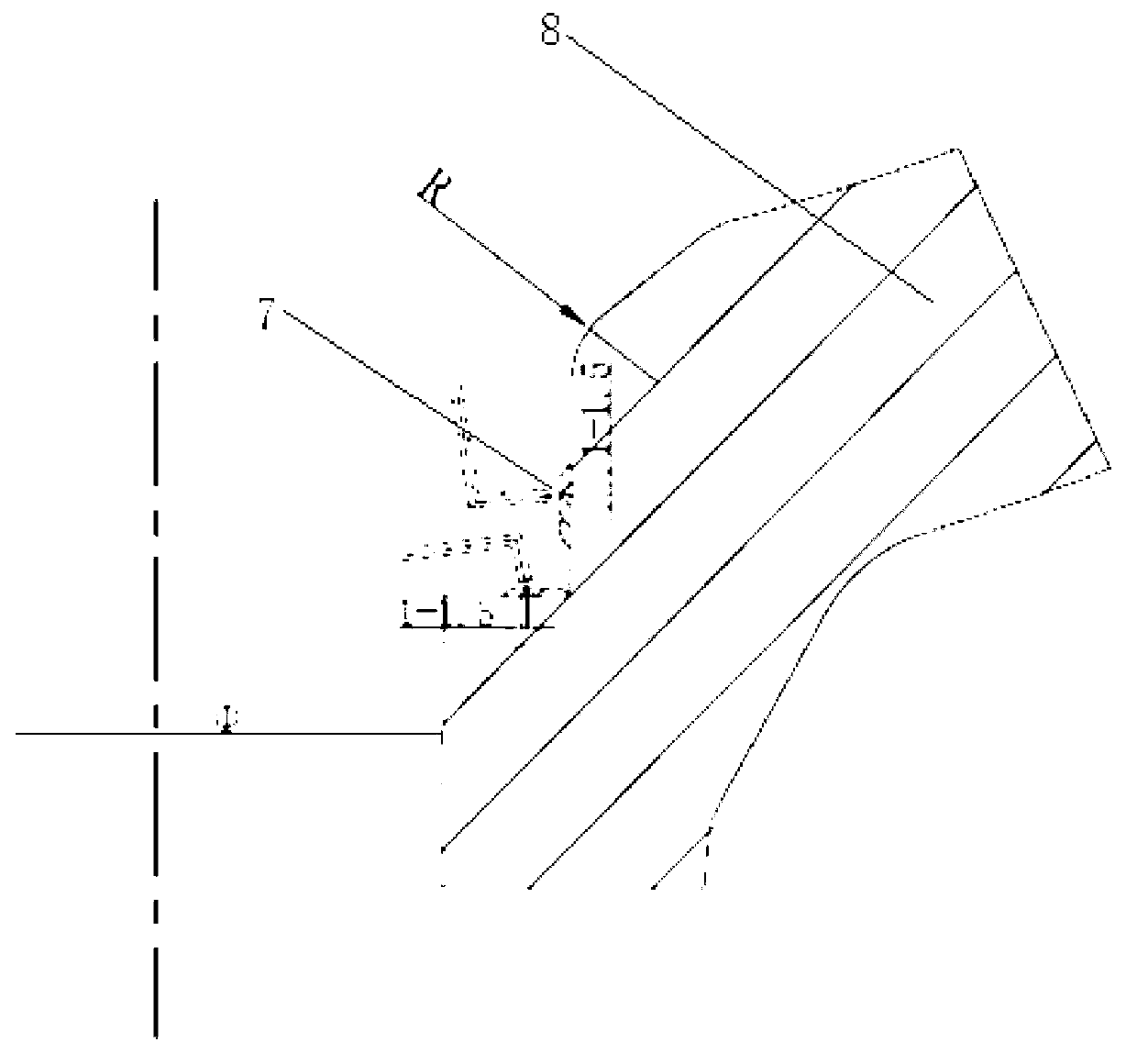

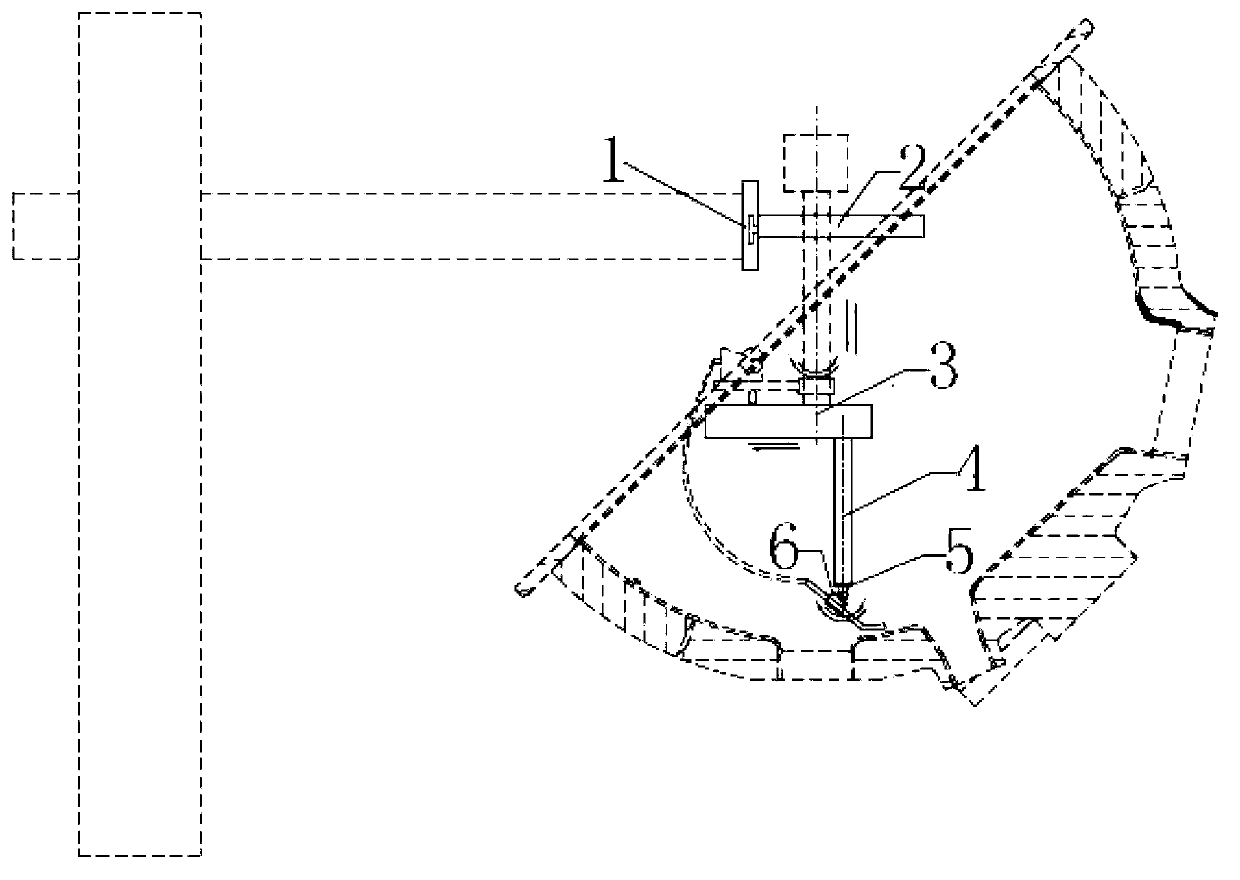

[0091] (1) use Figure 3-10 The welding device shown, such as figure 1 As shown, adjust the axis of the connecting pipe to be perpendicular to the horizontal plane; place the welding torch inside the connecting pipe or find the center on the end face, and ensure that the concentricity between the welding torch and the connecting pipe is 0-1mm;

[0092] (2) Store the information such as the welding torch rotation radius, lane change lifting amount and welding speed in the control cabinet, among which, the welding torch rotation radius is 200mm, the lane changing lifting amount is 3.5-4mm, and the welding speed is 400mm / min;

[0093] (3) Store the welding current and welding voltage into the welding power supply through the control box, wherein the welding current is 170-220A, and the welding voltage is 27-33V;

[0094] (4) Check the welding torch idling to ensure that the rotation of the welding torch and the lifting of the automatic lane change are smooth;

[0095] (5) Set t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com