Process method of continuously producing ultra-fine nickel powder

A process method and technology of nickel powder, which is applied in the field of continuous production of ultra-fine nickel powder by tubular reaction, can solve the problems of unstable production line, difficulty in reducing production cost, and high equipment requirements, so as to ensure uniformity, improve oxidation, The effect of reducing exposure time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

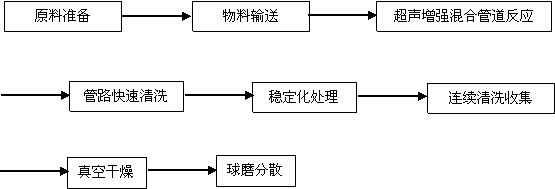

[0030] like figure 1 As shown, this method includes the following processes:

[0031] 1) Raw material preparation: 13Kg NiSO 4 . 6H 2 Dissolve O in 100L of deionized water, then add 225g of PVP, stir to dissolve and heat to 60°C to obtain solution A, which is stored in the first storage tank and the third storage tank; dissolve 5.2KgNaOH in 96L of deionized water , stir well and then heat, when the water temperature is 60°C, add 4L of 50% hydrazine hydrate and 1.85Kg NaBH 4 , fully stirred and dissolved and then heated to 60° C. to obtain a mixed solution B which was stored in the second storage tank and the fourth storage tank.

[0032] 2) Material transportation: Pump the two solutions A and B into the reaction pipeline through the metering pump, and control the flow rate of the two solutions at 0.5L / min respectively.

[0033] 3) Ultrasonic enhanced pipeline mixing reaction: Before the reaction, raise the ambient temperature of the reaction pipeline to 60°C and keep it ...

Embodiment 2

[0040] 1) Raw material preparation: 13Kg NiSO 4 . 6H 2 O was dissolved in 100L deionized water, then 225g of PVP was added, fully stirred and dissolved, and heated to 80°C to obtain solution A, which was stored in the first storage tank and the third storage tank; 5.2Kg NaOH was dissolved in 77.5L In deionized water, stir thoroughly and then heat. When the water temperature is approaching 80°C, add 22.5 L of hydrazine hydrate with a concentration of 50%, stir well and dissolve, then heat to 80°C to obtain mixed solution B, which is stored in the second storage tank and the fourth storage tank. in the storage tank.

[0041] 2) Material transportation: Pump the two solutions A and B into the reaction pipeline through the metering pump, and control the flow rate of the two solutions at 1.5L / min respectively.

[0042] 3) Ultrasonic enhanced pipeline mixing reaction: Before the reaction, raise the ambient temperature of the reaction pipeline to 80°C and keep it at a constant tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com