Preparation method for pazufloxacin mesilate for injection

A technology for pazufloxacin mesylate and injection, which is applied in the field of preparation of pazufloxacin mesylate for injection, can solve the problems of long sublimation time and cost waste in the freeze-drying process, and achieve the time limit of the freeze-drying process The effect of shortening, excellent product quality, and production cost reduction

Active Publication Date: 2013-09-04

SICHUAN BAILI PHARM CO LTD

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, in the production process of pazufloxacin mesylate for injection, the sublimation time of the freeze-drying process is too long and the cost is wasted too much

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

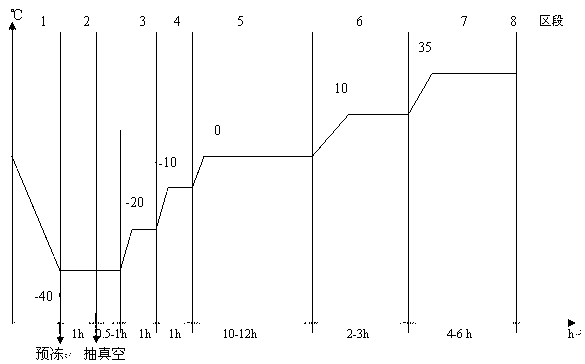

Login to View More Abstract

The invention provides a preparation method for pazufloxacin mesilate for injection. The preparation method comprises the following steps of: preparing the pazufloxacin mesilate and mannitol according to a prescription, and regulating pH values to be 3.0-4.0; adding a proper amount of needle active carbon, heating the mixture to be 70-80 DEG C, and carrying out decoloring after stirring for 15-20 minutes; putting an encapsulated semi-finished product into a freezing vacuum drier, controlling the temperature to be below -30 DEG C and carrying out prefreezing for 1-1.5 hours; when the temperature of a cold trap of the drier is lower than -40 DEG C, vacuumizing until the pressure is 20 Pa, and carrying out constant-temperature drying for 0.5-1 hour; raising the temperature of a separation board of the drier to be -10 DEG C, carrying out the constant-temperature drying for 0.5-1 hour; and raising the temperature of the separation board to be 0 DEG C, carrying out the constant-temperature drying until the waterline of the product reaches the bottom, raising the temperature to be 10 DEG C in a temperature manner, after carrying out the constant-temperature drying until the temperature of the product approximates to 0 DEG C, raising the temperature of the separation board to be 35 DEG C, and judging that the product is qualified after carrying out the constant-temperature drying until reaching the end point. The preparation method has the advantages that the production cost is lowered and the product quality is improved and is more suitable for industrial production.

Description

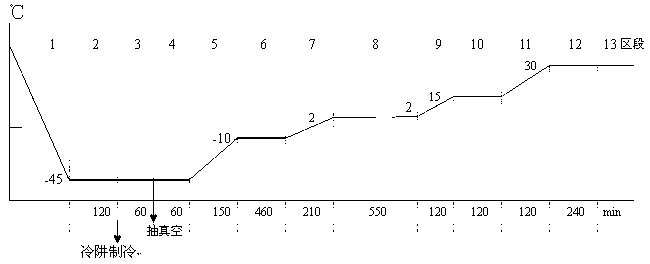

technical field The invention belongs to the technical field of chemical pharmacy and relates to a preparation method of pazufloxacin mesylate for injection. Background technique Pazufloxacin mesylate is the fourth-generation quinolone antibacterial drug, widely used in respiratory tract infection, genitourinary system infection, surgical infection, etc. Clinical studies of pazufloxacin mesylate have shown that its curative effect is superior to that of levofloxacin, ofloxacin and ciprofloxacin currently on the domestic market. Compared with the quinolone antibacterial drugs commonly used in domestic clinical practice, the drug resistance and safety are improved, and the clinical application prospect is very broad. The chemical structure of Pazufloxacin Mesilate for Injection is as follows: . The sterile freeze-dried powder of pazufloxacin mesylate for injection is not easily oxidized and is good for long-term storage, and has been widely used in practice. At present...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A61K9/19A61K31/5383A61P31/04

Inventor 朱义王一茜梁臻

Owner SICHUAN BAILI PHARM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com