Measuring device and method for vibration of flexible cantilever on basis of machine vision

A flexible cantilever and machine vision technology, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of high cost, slow measurement speed, phase lag, etc., and achieve high real-time performance and accuracy without changing Vibration characteristics and low measurement noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

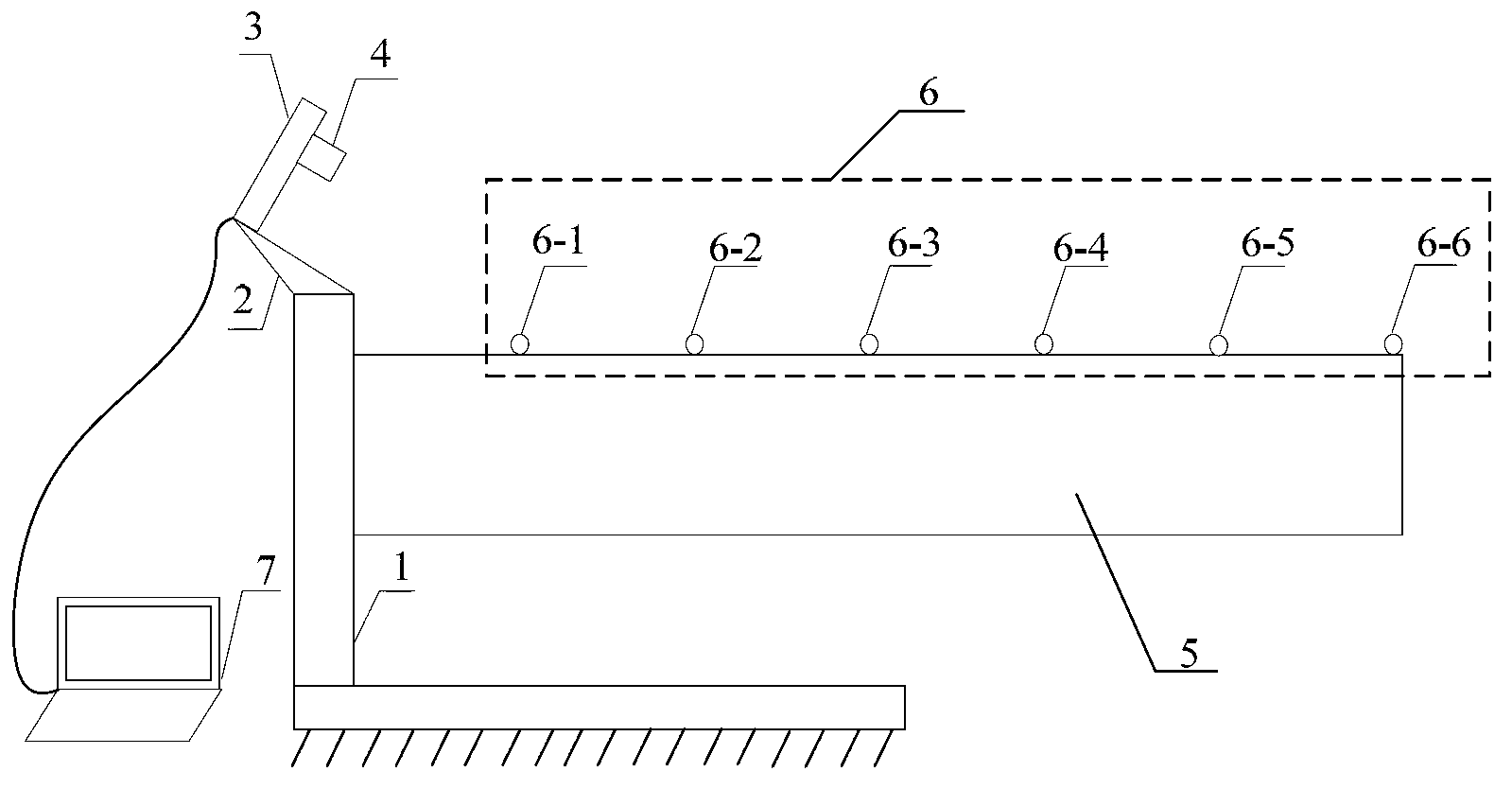

[0066] Taking the flexible cantilever beam structure for simulating solar panels as an example, the device and method for measuring the vibration of the flexible cantilever beam based on machine vision in the present invention are as follows.

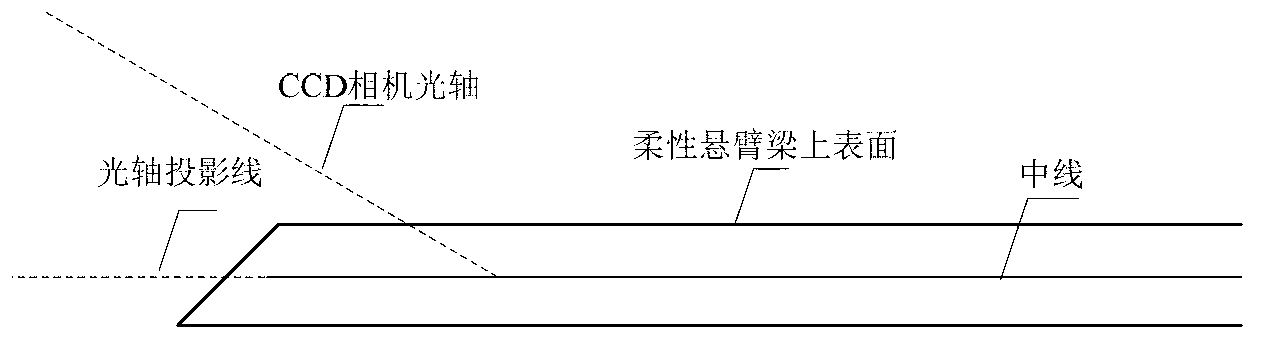

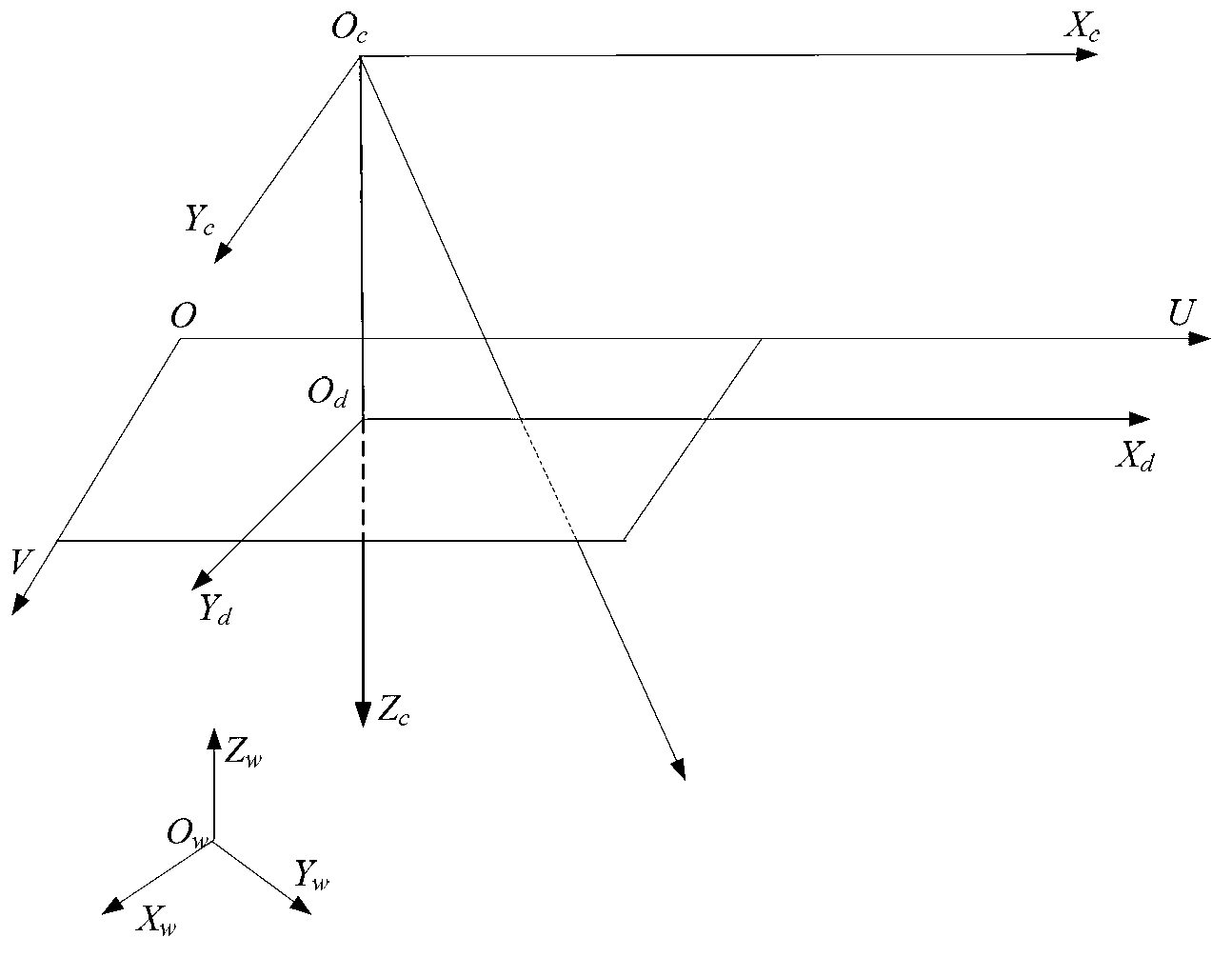

[0067] combine figure 1 , the present invention is based on the measuring device of the flexible cantilever beam vibration of machine vision, comprises fixed support 1, flexible cantilever beam 5, camera support 2, CCD camera 3, lens 4, 6 LED light-emitting tubes 6 and PC 7; One end of the cantilever beam 5 is fixed on the fixed bracket 1, and the other end is a free end. The geometric dimensions of the flexible cantilever beam 5 are 1200mm x 80mm x 2mm in length x width x height; Respectively, the first LED light-emitting tube 6-1, the second LED light-emitting tube 6-2, the third LED light-emitting tube 6-3, the fourth LED light-emitting tube 6-4, the fifth LED light-emitting tube 6-5 and the sixth LED light-emitting tube The luminou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com