Method for preparing enhanced belt for nano SiO2/PET enhanced RTP

A technology of enhancement tape and nanometer, which is applied in the field of preparation of enhancement tape for nano-SiO2/PET enhanced RTP, and can solve the problems that have not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

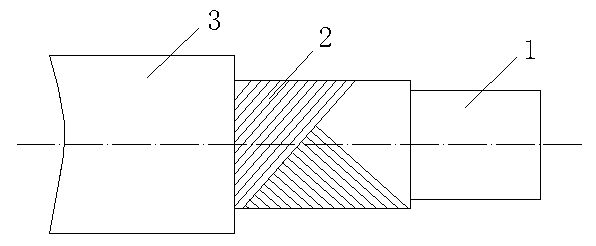

Image

Examples

specific Embodiment approach

[0025] A typical specific implementation is:

[0026] A kind of nano-SiO2 / PET strengthens the preparation method of RTP with strengthening tape, and its steps are:

[0027] 1. Put 8.0kg of nano-SiO2 uniformly dispersed in ethylene glycol, 390kg of ethylene glycol into the slurry mixing tank, stir for 30 minutes, then put in 860kg of terephthalic acid, 300g of antimony trioxide, stir for 2 hours, and then put in ester During the esterification process, the temperature of the reactor should be controlled at 250~260°C, the pressure at 1.5~2.0bar, and the reaction time about 3.5~4.0h. The chemical solution is transferred into the polycondensation kettle, and at this time, 5.0kg of KH-560 silane coupling agent and 400g of trimethyl phosphate are added. The conditions of polycondensation reaction are: the temperature in the kettle is 270~290℃, the vacuum degree is ≤80bar, and the reaction time is about 2.5~3.0 h, when the intrinsic viscosity is about 0.7dl / g, the reaction is over, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com