A kind of preparation method of silicon dioxide coated microcapsule of essential oil

A technology of silica and microcapsules, which is applied in the direction of microcapsule preparation and microsphere preparation, can solve the problems of lack of mutual adhesion and failure of Pickering emulsification effect, etc., achieve effective encapsulation, fast and convenient preparation process, small size small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

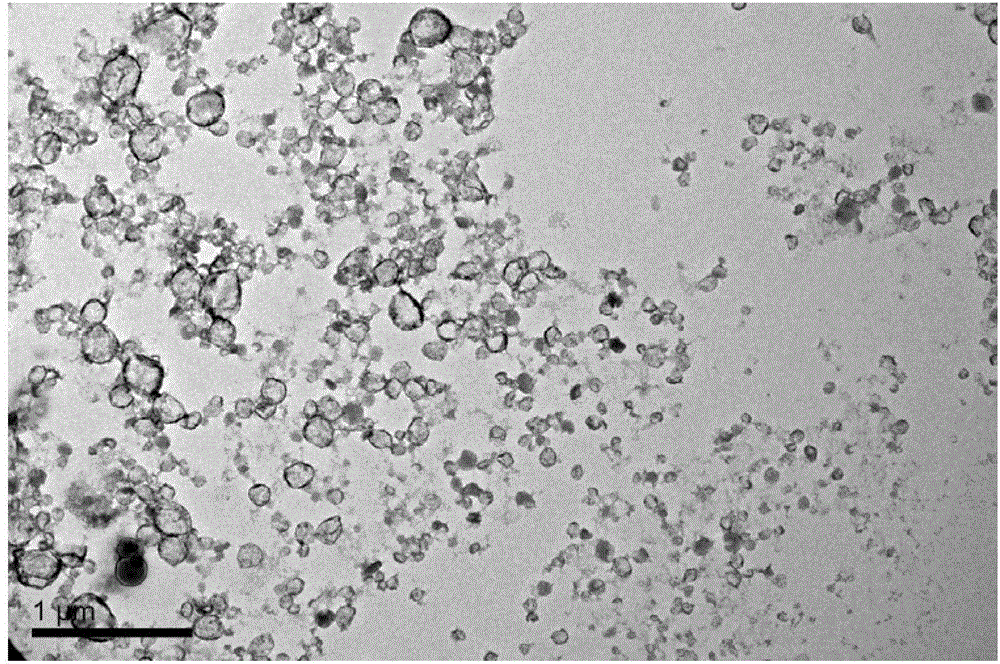

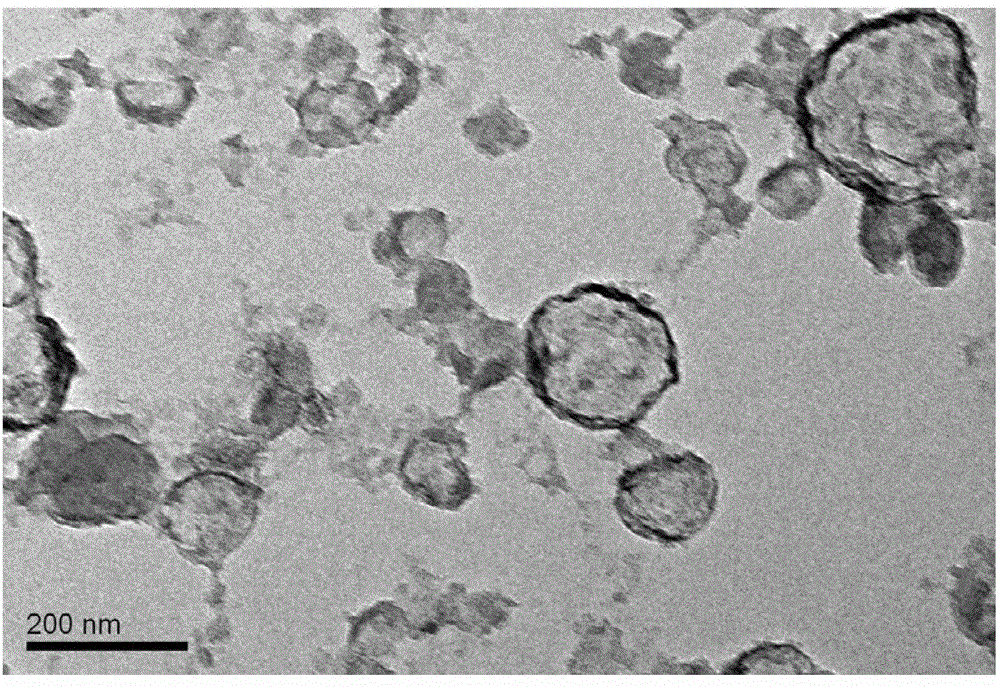

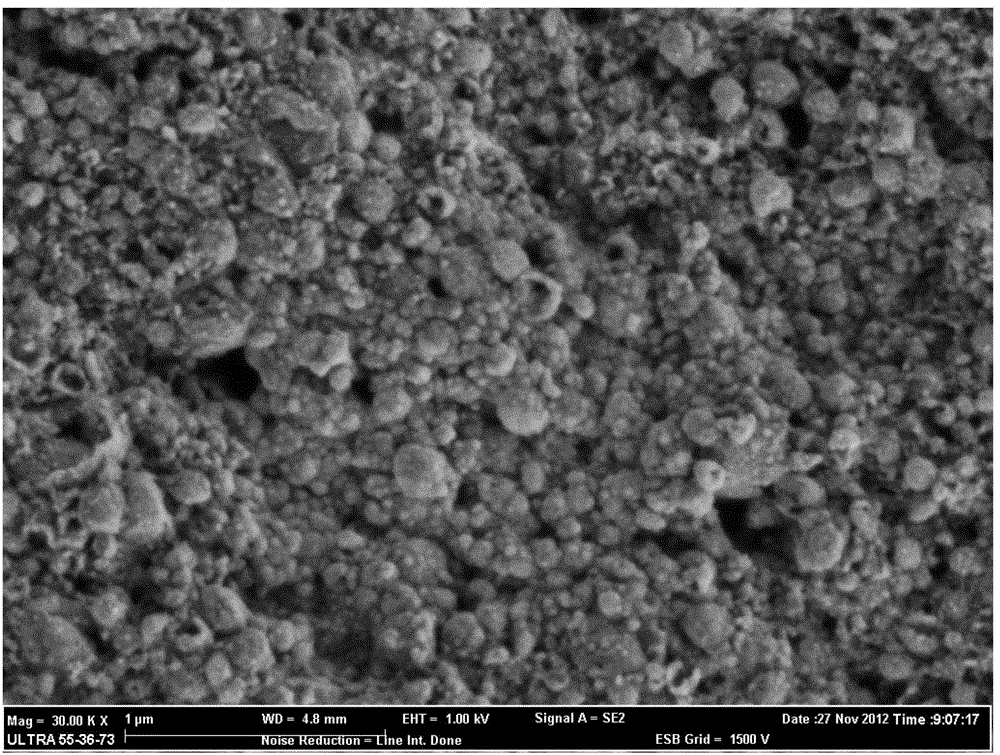

Image

Examples

Embodiment 1~15

[0040] (1) Mix essential oil, silica precursor TEOS and 0.5g co-emulsifier (isohexadecane, HD) to obtain an oil phase mixture;

[0041] (2) Add acetic acid aqueous solution to the aqueous dispersion of silicon dioxide to adjust the pH to 4.5-5.7, Example 1 to adjust the pH to 4.5, Example 11 to adjust the pH to 5.7, and other examples to adjust the pH to 5, and then follow the steps (1) Mix the oil phase mixture, add an appropriate amount of water, so that the total amount after mixing is adjusted to 100g, and then put it in an ice-water bath, and disperse it by ultrasonic (ultrasonic 5s, interval 5s, effective ultrasonic time is 500s) to obtain fine Emulsion, add 0.15g of emulsifier cetyltrimethylammonium bromide (CTAB) to the microemulsion after ultrasonic dispersion;

[0042] (3) Add the fine emulsion after adding the emulsifier at a stirring rate of 200-300r·min -1 The reaction is blocked at 10° C. to 60° C. for 1 h to 6 h to obtain a highly dispersible colloidal emulsion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com