Method for improving performance of anode material LiFePO4 for lithium ion cell

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve problems such as high processing costs, complicated process steps, and increased battery production costs, and achieve high electronic conductivity and good circulation Performance and Rate Capability, Effect of Excellent Li-ion Diffusion Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This experiment is realized through the following steps: 1. The Fe(CH 3 COO) 2 4H 2 O (analytical grade), LiCH 3 COO·2H 2 O (analytical pure) and NH 4 h 2 PO 4 (Analytical pure) in triethylene glycol (TEG for short) mixed evenly and boiled and refluxed for 16h to prepare pure phase LiFePO 4 Materials; 2. Pure phase LiFePO with deionized water 4 Mix evenly with graphene oxide and carbon nanotubes (the mass fraction of graphene in the final electrode material is 2%, the mass fraction of carbon nanotubes is 3%, that is, the total carbon content is 5%), in the air at 60°C Drying for 24 hours; 3. Heat-treat the powder obtained in step 2 at a high temperature of 700° C. for 2 hours in argon.

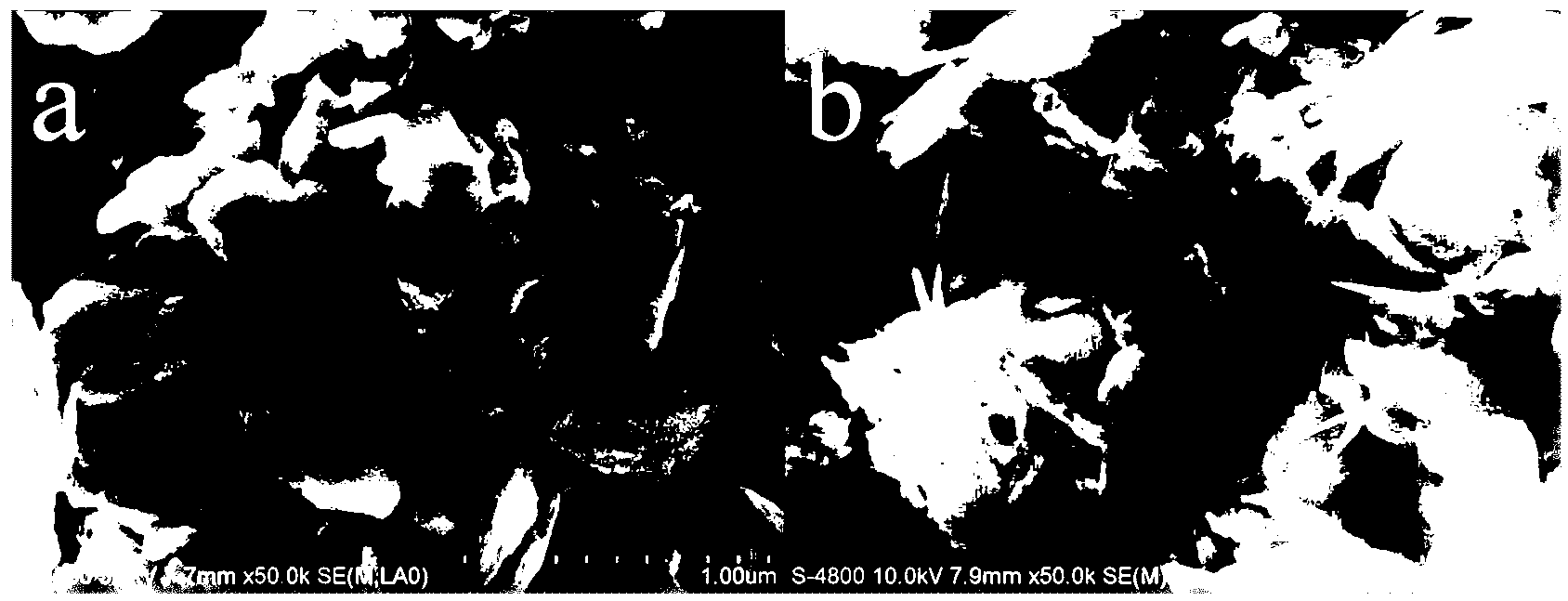

[0022] figure 1 is LiFePO before modification 4Cathode material (a) and LiFePO obtained after modification 4 Comparison of the microscopic morphology of the positive electrode material (b). It can be seen from the figure that the pure phase LiFePO without doped graphene and c...

Embodiment 2

[0027] This experiment is realized through the following steps: 1. The Fe(CH 3 COO) 2 4H 2 O (analytical grade), LiCH 3 COO·2H 2 O (analytical pure) and NH 4 h 2 PO 4 (Analytical pure) in triethylene glycol (TEG for short) mixed evenly and boiled and refluxed for 32h to prepare pure phase LiFePO 4 Materials; 2. Pure phase LiFePO with deionized water 4 Mix evenly with graphene oxide and glucose (the mass fraction of graphene in the final electrode material is 1%, the mass fraction of amorphous carbon is 2%, that is, the total carbon content is 3%), and dry at 80°C in the air for 16h 3. Heat the powder obtained in step 2 at 600°C for 3 hours in argon.

[0028] Modified LiFePO 4 The electrode, electronic conductivity and ion diffusion rate are significantly improved, the charge transfer ability is greatly increased, and the cycle performance and rate performance are significantly improved. Figure 5 It is the LiFePO obtained after modification treatment 4 The discharge...

Embodiment 3

[0031] This experiment is realized through the following steps: 1. The Fe(CH 3 COO) 2 4H 2 O (analytical grade), LiCH 3 COO·2H 2 O (analytical pure) and NH 4 h 2 PO 4 (Analytical pure) Mix well in tetraethylene glycol and boil and reflux for 12h to prepare pure phase LiFePO 4 Materials; 2. Pure phase LiFePO with deionized water 4 Mix it with glucose evenly (the total carbon content in the final electrode material is 4%), and dry it in the air at 50°C for 24h; 3. Heat the powder obtained in step 2 at 800°C in nitrogen for 1h. The results showed that, compared with before modification, the modified LiFePO 4 The electronic conductivity of the electrode and the diffusion rate of lithium ions are significantly improved, and the discharge specific capacity is also greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com