Automatic positioning control method of belt pulley trolley for coal blending in coking plant

An automatic positioning and pulley technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of not very flexible limitations, troublesome sensor installation, limited automatic control functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

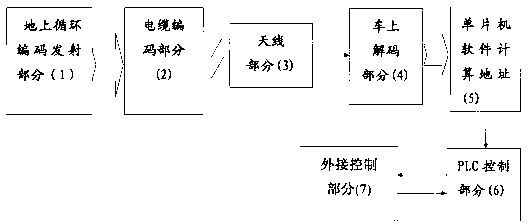

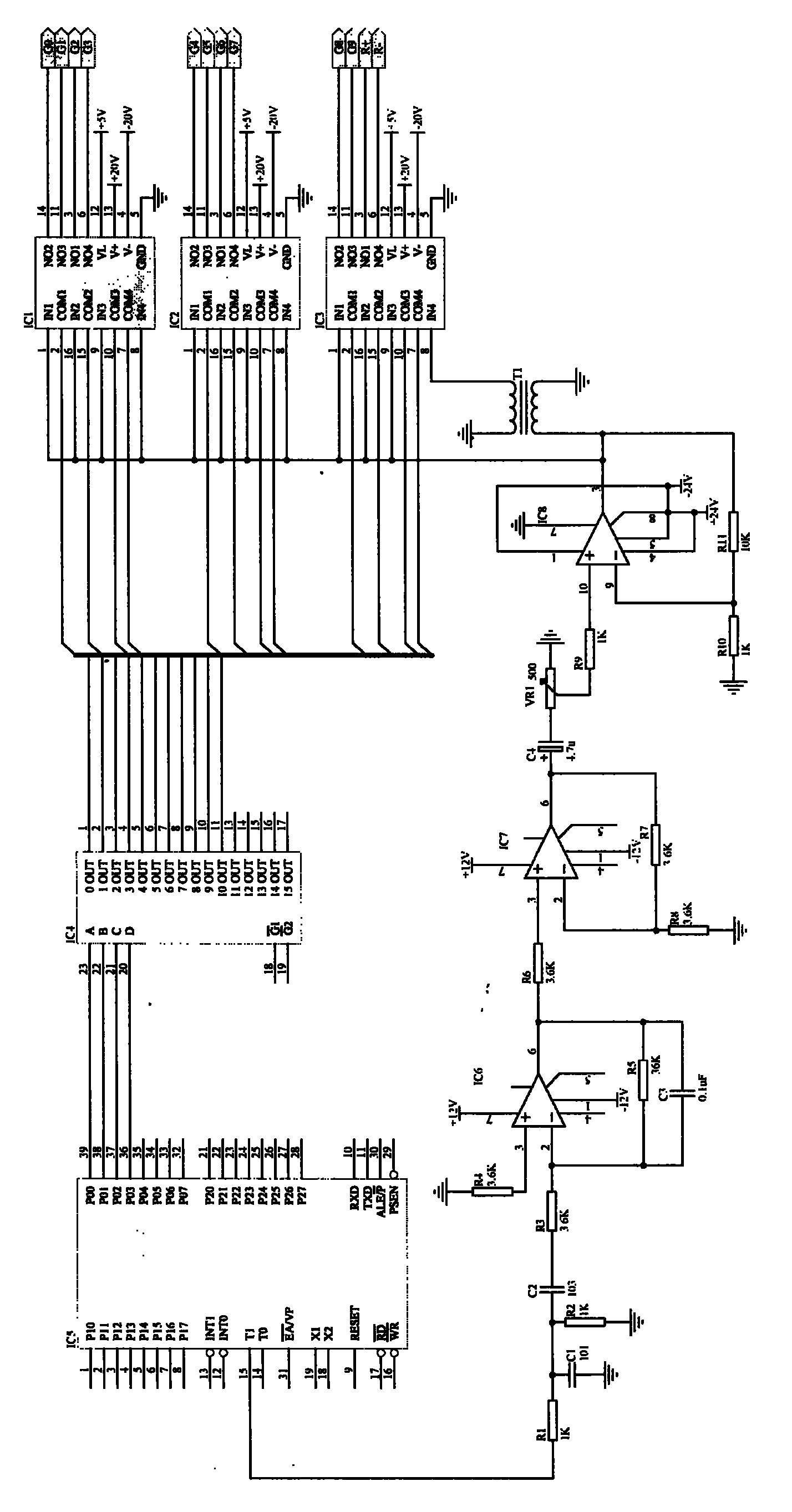

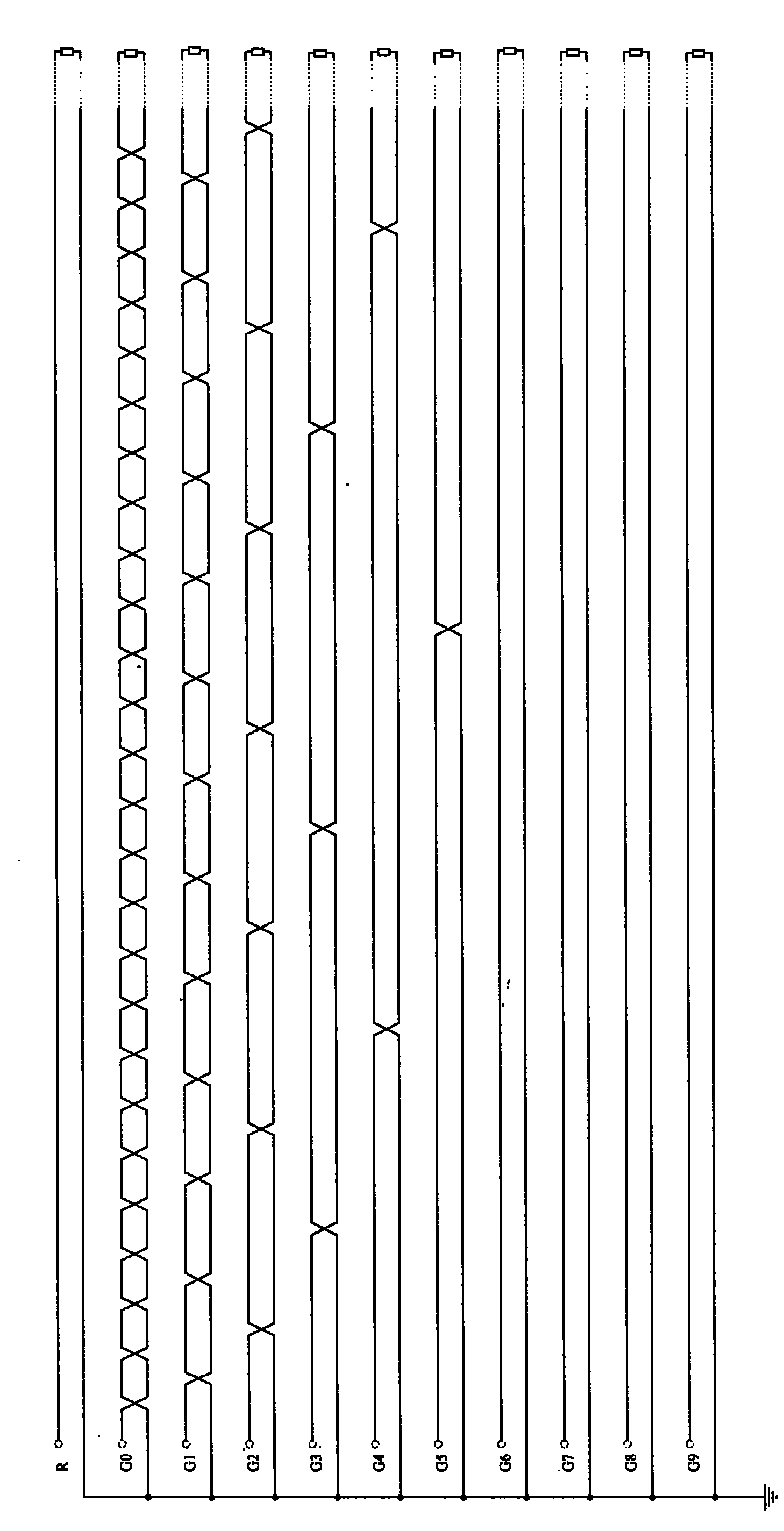

[0030] Depend on figure 1 It can be seen that the present invention consists of an above-ground cyclic coding transmission part (1), a cable coding part (2), an antenna part (3), an on-board decoding part (4), a single-chip computer software calculation address part (5), and a PLC control part (6) , the external control part (7), the ground cyclic coding transmission part (1) generates a 49KHz carrier signal, the output of the carrier signal is connected to the input of the cable coding part (2), and the cable coding part (2) generates an address by crossing the line Gray coded signal, the antenna part (3) senses the address Gray coded signal and transmits it to the space, and connects with the input of the decoding part (4) on the car, and the decoding part (4) on the car sends the address Gray coded by the antenna part (3) The encoded signal is converted into a digital symbol signal, and the digital symbol signal is transmitted to the input terminal of the single-chip comput...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com