Metal oil tank mould-proof conductive electrostatic anticorrosive coating

An anti-corrosion coating and electrostatic conductive technology, applied in conductive coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., can solve the problems of combustion and explosion, and can not inhibit the growth of microorganisms, etc., to achieve dense coating film and excellent shielding Excellent performance and mold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

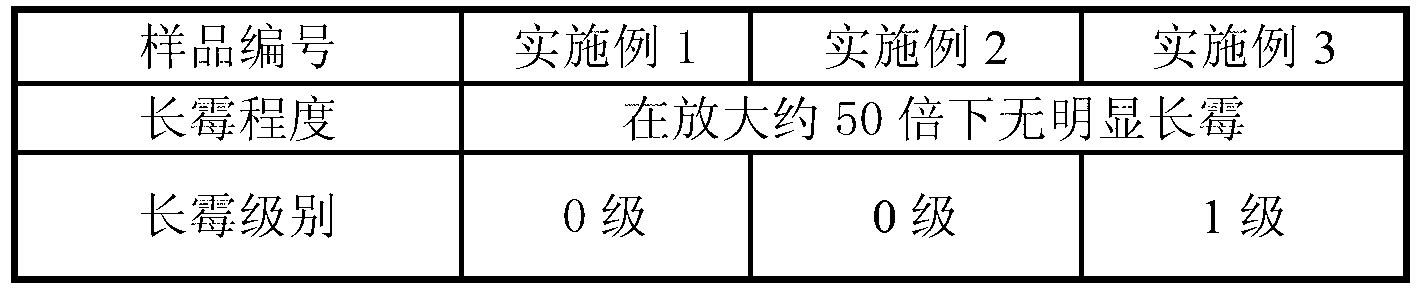

Embodiment 1

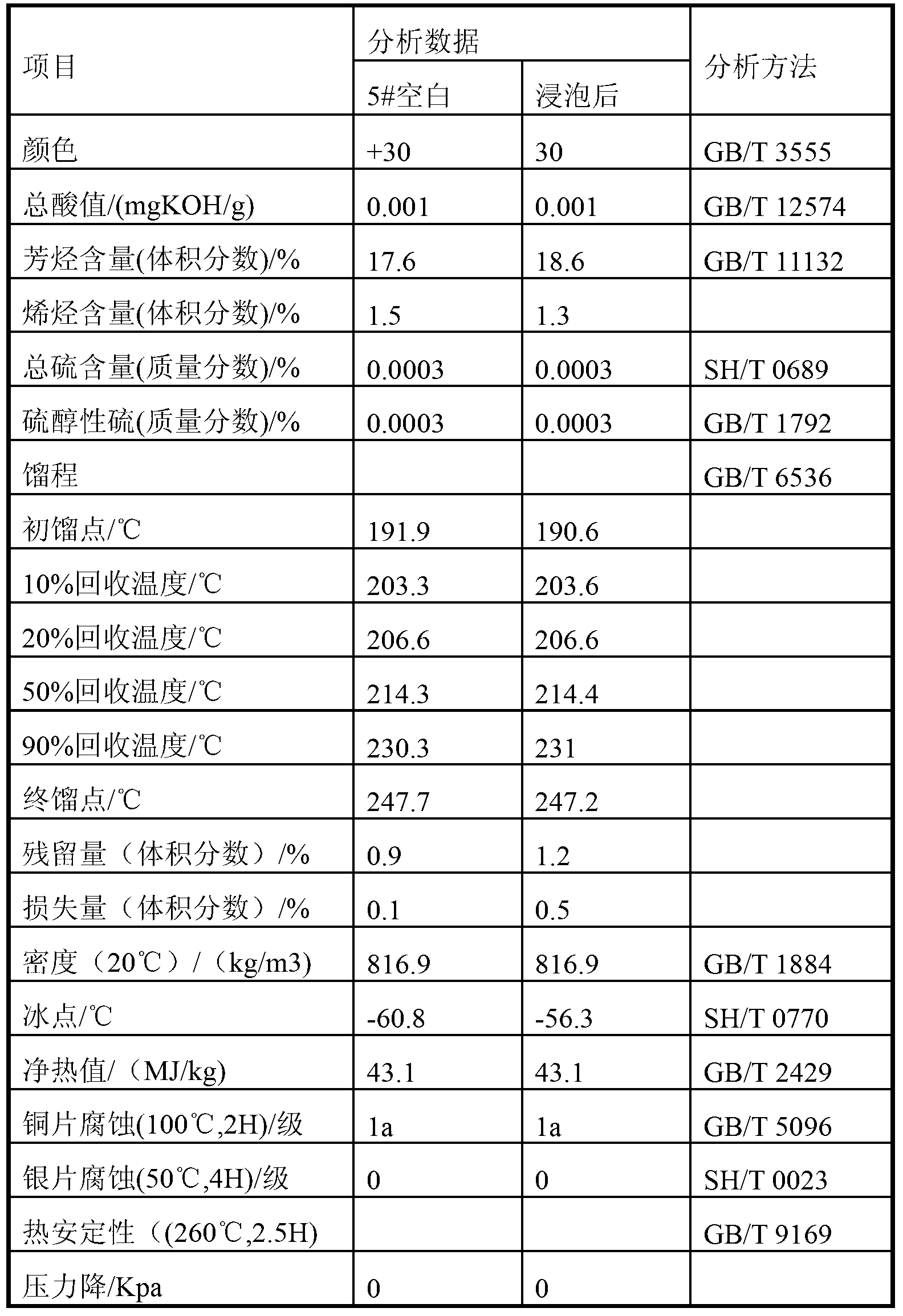

[0045] formula:

[0046] Component A: bisphenol A modified epoxy resin, 28.4kg, xylene 25kg, n-butanol 8.4kg, BYK-104s0.9kg, titanium dioxide 13kg, organic bentonite 0.3kg, antimony trioxide 1.0kg, precipitate Barium sulfate 2kg, Bioxad CI-SF 0.004kg, zinc oxide whiskers 1.9kg, conductive mica powder 20kg

[0047] Component B: low molecular weight polyamide resin T31, 40kg, aliphatic modified amine curing agent 651, 10kg, n-butanol 5kg. T31:651:n-butanol=40:10:5

[0048] Preparation:

[0049] Preparation of mixed sterilizing solution: Weigh 75kg of xylene solution and 25kg of n-butanol solution, mix under medium-speed stirring, add Bioxad CI-SF0.004kg to obtain mixed sterilizing solution, and let stand;

[0050] Component A configuration: Weigh 33kg of the mixed sterilizing solution and mix it with 28.4kg of bisphenol A modified epoxy resin. After the resin is dissolved, add 0.9kg of dispersant BYK-104s under stirring, and then add zinc oxide whiskers 1.9kg, fully stirred ...

Embodiment 2

[0059] Component A: 26.7kg of bisphenol A modified epoxy resin, 24.6kg of xylene, 7.0kg of n-butanol, 1.0kg of BYK-104s, 8.0kg of titanium dioxide, 0.3kg of organic bentonite, 1.1kg of antimony trioxide, Precipitated barium sulfate 2.8kg, Bioxad 0.008kg, zinc oxide whiskers 2.2kg, conductive mica powder 25kg

[0060] Component B: Composite epoxy curing agent: T31, 35kg; 651, 15kg; n-butanol 7kg. The weight ratio is T31:651:n-butanol=35:15:7

[0061] Preparation:

[0062] Preparation of mixed sterilizing solution: Weigh 77.8kg of xylene solution and 22.2kg of n-butanol solution, mix under medium-speed stirring, add CI-SF0.008kg to obtain mixed sterilizing solution, and let stand;

[0063] Component A configuration: Weigh 31.6kg of mixed sterilizing solution and mix it with 26.7kg of bisphenol A modified epoxy resin. After the resin is dissolved, add dispersant 104s1.0kg under stirring state, and then add zinc oxide whiskers 2.2 kg, fully stirred for 60 minutes, added the res...

Embodiment 3

[0076] Component A: Bisphenol A modified epoxy resin 25kg, xylene 30kg, n-butanol 7.4kg, BYK-104s0.7kg, titanium dioxide 9.0kg, organic bentonite 0.3kg, antimony trioxide 0.9kg, precipitated sulfuric acid Barium 3.0kg, Bioxad 0.0013kg, DCOIT-30, 0.4kg, zinc oxide whiskers 2.5kg, conductive mica powder 21.5kg

[0077] Component B: composite epoxy curing agent: T31, 38kg; 651, 8kg; n-butanol 8kg. T31:651:n-butanol=38:8:8

[0078] Preparation:

[0079] Preparation of mixed sterilizing solution: Weigh 80.2kg of xylene solution and 19.8kg of n-butanol solution, mix under medium-speed stirring, add 0.013kg of CI-SF to obtain mixed sterilizing solution, and let stand;

[0080] Component A configuration: Weigh 37.4kg of mixed sterilizing solution and mix it with 25kg of bisphenol A modified epoxy resin. After the resin is dissolved, add 0.7kg of dispersant 104s under stirring, and then add 2.5kg of zinc oxide whiskers , fully stirred for 60 minutes, added the rest of the functional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com