Vitreous building sanitary ceramic with low-expansion and high-infrared function prepared by waste gangue and preparation method of vitreous building sanitary ceramic

A technology of sanitary ceramics and functional porcelain, which is applied in the field of low-expansion high-infrared functional porcelain building sanitary ceramics and its preparation, can solve problems such as air, landscape, environmental adverse effects, occupation of high-quality land resources, water pollution, etc., and achieve improvement The effect of product added value and market competitiveness, improvement of quality of life, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

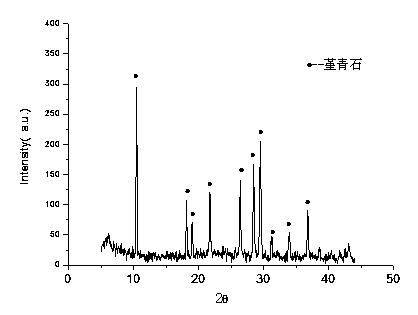

Image

Examples

Embodiment 1

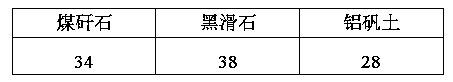

[0016] Step 1: The green body is composed according to the weight percentage in the table below, and it is prepared by batching, ball milling, sieving, aging, grouting, and drying for later use.

[0017]

[0018] Step 2: The glaze is composed according to the weight percentage of the glaze in the following table, and it is prepared by batching, ball milling and sieving.

[0019]

[0020] The third step: Apply the glaze obtained in the second step to the green body obtained in the first step, dry and fire to obtain the finished product. The sintering temperature is 1250°C and the holding time is 120 minutes.

Embodiment 2

[0022] Step 1: The green body is composed according to the weight percentage in the table below, and it is prepared by batching, ball milling, sieving, aging, grouting, and drying for later use.

[0023]

[0024] Step 2: The glaze is composed according to the weight percentage of the glaze in the following table, and it is prepared by batching, ball milling and sieving.

[0025]

[0026] The third step: Apply the glaze obtained in the second step to the green body obtained in the first step, dry and fire to obtain the finished product. The sintering temperature is 1270°C and the holding time is 60 minutes.

Embodiment 3

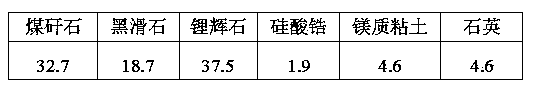

[0028] Step 1: The green body is composed according to the weight percentage in the table below, and it is prepared by batching, ball milling, sieving, aging, grouting, and drying for later use.

[0029]

[0030] Step 2: The glaze is composed according to the weight percentage of the glaze in the following table, and it is prepared by batching, ball milling and sieving.

[0031]

[0032] The third step: Apply the glaze obtained in the second step to the green body obtained in the first step, dry and fire to obtain the finished product. The sintering temperature is 1270°C and the holding time is 30 minutes.

[0033] The RPZ-01 thermal expansion coefficient tester produced by Changsha Instrument Factory, the IR-2 dual-band infrared emissivity measuring instrument produced by Shanghai Institute of Technical Physics, Chinese Academy of Sciences, and the WOW-10 microcomputer control produced by Xi'an Lichuang Metering Instrument Co., Ltd. Electronic universal testing machine,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com