Method for producing industrial potassium chloride through hot melting crystallization of underground embedded solid potassium salt mine

A potassium chloride and potassium salt mine technology, applied in the direction of alkali metal chloride and the like, can solve the problems of lack of large soluble solid potassium salt deposits, weak potassium chloride technology, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

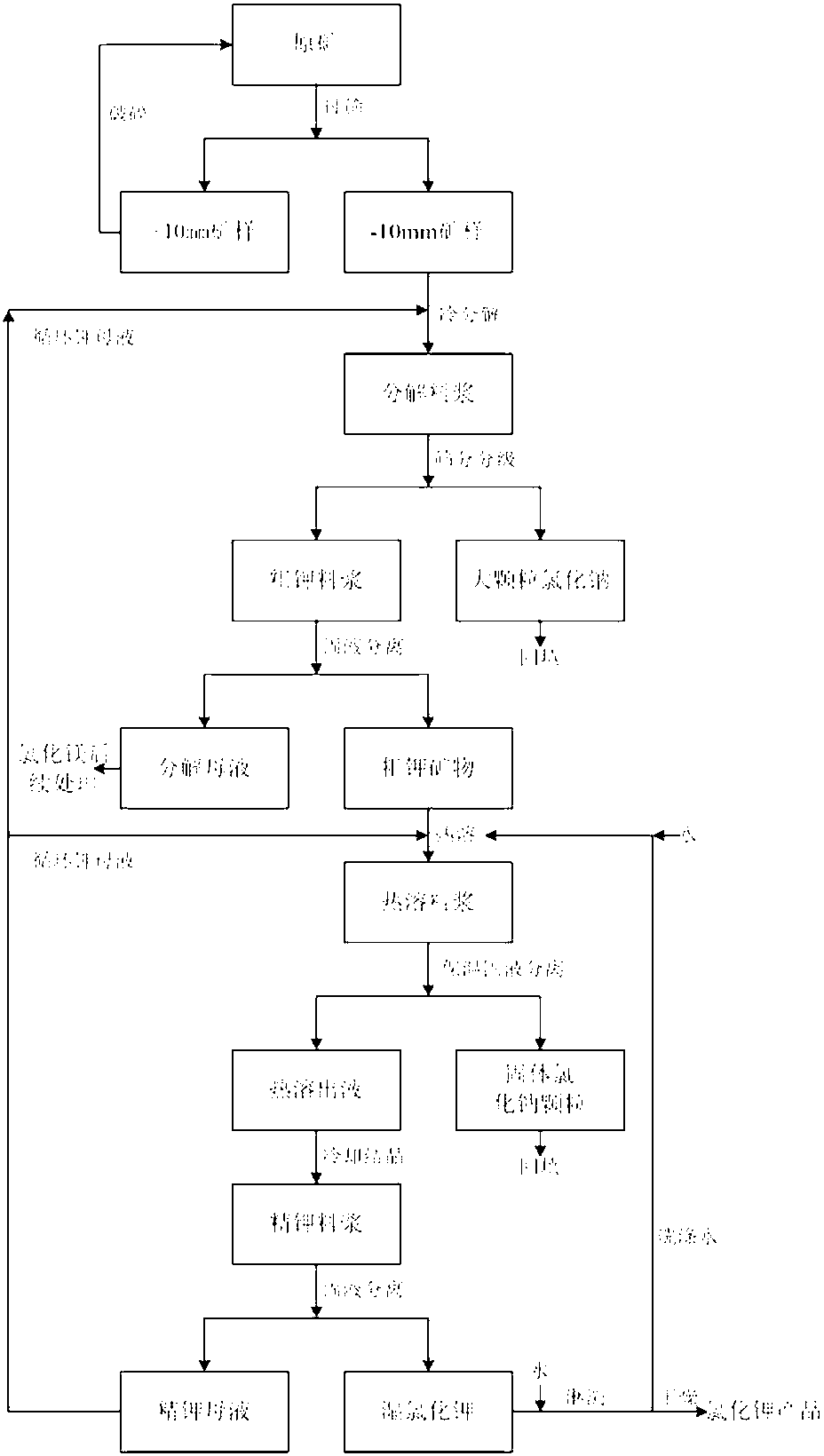

Method used

Image

Examples

Embodiment 1

[0023] (1) Raw ore (KCl: 13.89% NaCl: 49.23% MgCl 2 : 15.50%H 2 O: 21.38%) is crushed by a hammer crusher until the particle size is less than 10mm, 1000g of raw ore is taken, and 428.09g of circulating potassium mother liquor is added to decompose in the decomposition tank. The decomposition reaction time is 15 minutes at room temperature, and 1428.09g of slurry is obtained. ;

[0024] (2) Slurry is subjected to wet sieving, Taylor standard sieve mesh is 16 meshes, and 470.07g of large-particle solid phase sodium chloride oversize and mixed slurry undersize with solid phase potassium chloride are obtained. Sodium chloride was directly backfilled downhole, and the underscreen was separated from solid and liquid by suction filtration to obtain 337.06g of crude potassium mineral and 620.96g of decomposed mother liquor;

[0025] (3) Add 573.02g of circulating potassium mother liquor, 239.74g of water and 30.86g of washing water to the crude potassium mineral, heat-dissolve at 9...

Embodiment 2

[0028] (1) Raw ore (KCl: 13.73% NaCl: 49.50% MgCl 2 : 15.40%H 2 O: 21.37%) was crushed by a hammer crusher until the particle size was less than 10mm, 1000g of raw material ore was taken, and 434.78g of circulating potassium mother liquor was added to decompose in the decomposition tank. The decomposition reaction time at room temperature was 30 minutes, and 1434.78g of slurry was obtained;

[0029] (2) The slurry is wet screened, and the Taylor standard sieve mesh is 35 meshes, and 540.24g of large-particle solid phase sodium chloride oversize and mixed slurry undersize with solid phase potassium chloride are obtained. Sodium chloride was directly backfilled downhole, and the underscreen was separated from solid and liquid by suction filtration to obtain 280.78g of crude potassium mineral and 613.77g of decomposed mother liquor;

[0030] (3) Add 605.86g of circulating potassium mother liquor, 244.20g of water and 28.68g of washing water to the crude potassium mineral, heat-d...

Embodiment 3

[0033] (1) Raw ore (KCl: 17.94% NaCl: 36.26% MgCl 2 : 20.52%H 2 O: 25.28%) is crushed by a hammer crusher until the particle size is less than 10mm, 1000g of raw ore is taken, and 416.66g of circulating potassium mother liquor is added to decompose in the decomposition tank. The decomposition reaction time is 45 minutes at room temperature, and 1416.66g of slurry is obtained. ;

[0034] (2) The slurry is wet screened, and the Taylor standard sieve mesh is 20 meshes, and 371.81g of large-particle solid phase sodium chloride oversize and mixed slurry undersize with solid phase potassium chloride are obtained. Sodium chloride was directly backfilled downhole, and the underscreen was separated from solid and liquid by suction filtration to obtain 278.13g of crude potassium mineral and 766.72g of decomposed mother liquor;

[0035](3) Add 623.01g of circulating potassium mother liquor, 271.56g of water and 32.16g of washing water to the crude potassium mineral, heat-dissolve at 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com