Microcrystalline semiconductor thin film production process

A thin-film manufacturing method and technology for microcrystalline semiconductors, which are applied in the manufacturing of semiconductor/solid-state devices, semiconductor devices, gaseous chemical plating, etc., can solve the problems of internal oxidation, adverse effects of solar cell characteristics, surface oxidation, etc., and achieve uniform crystallization efficiency, high performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

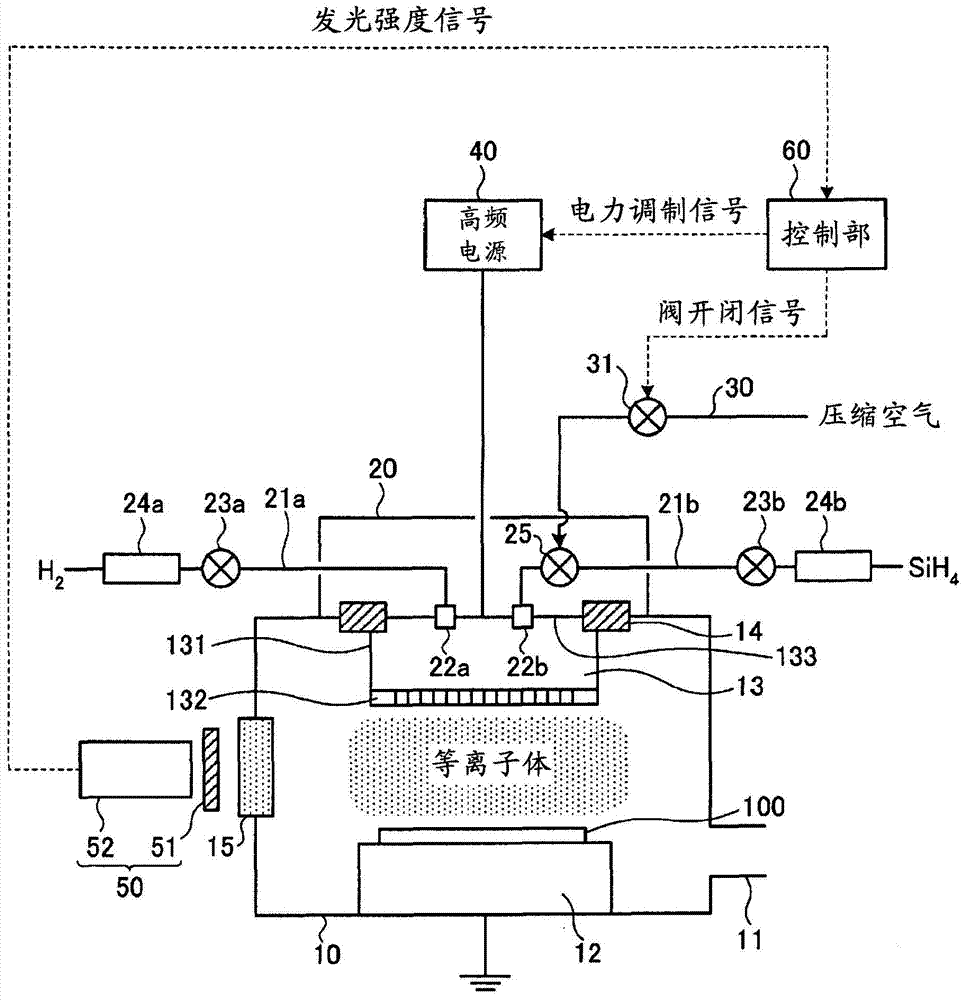

[0034] figure 1 It is a diagram schematically showing an example of the structure of the microcrystalline semiconductor thin film manufacturing apparatus according to Embodiment 1 of the present invention. This microcrystalline semiconductor thin film manufacturing apparatus is based on a conventional plasma CVD apparatus, and includes a substrate stage 12 and a plasma electrode 13 in a vacuum chamber 10 in which an atmosphere for forming a semiconductor thin film is formed, and is provided as the plasma electrode 13. The surfaces facing the substrate stage 12 are parallel to each other. In the vacuum container 10, a gas exhaust pipe 11 is provided, and the gas in the vacuum container 10 is exhausted by an unillustrated vacuum pump connected to the gas exhaust pipe 11, and the inside of the vacuum container 10 is set to a predetermined value. Vacuum.

[0035] The substrate stage 12 is electrically grounded, and has a structure on which the substrate 100 to be subjected to th...

Embodiment approach 2

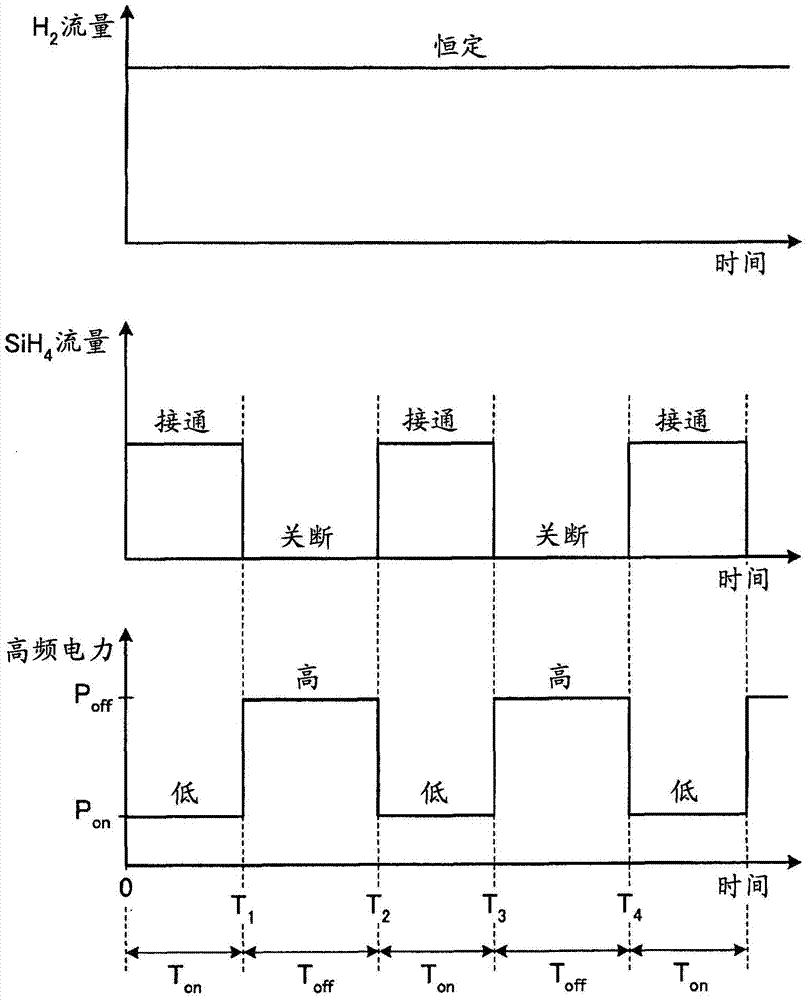

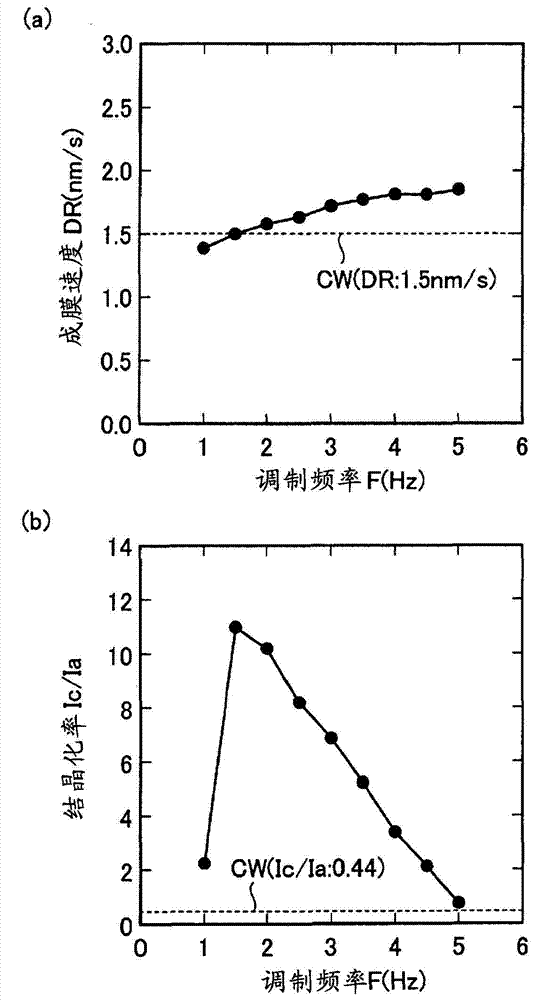

[0091] In the above-mentioned Example 1, it was explained that the SiH 4 The duty cycle R of the on / off modulation of the gas supply becomes constant so that the SiH 4 The frequency F of the ON / OFF modulation of the gas supply is changed over time to form a film, but on the contrary even if the SiH 4 The frequency F of the on / off modulation of the gas supply becomes constant such that the SiH 4 Varying the duty ratio R of the on / off modulation of the gas supply over time can also improve the uniformity of crystallinity. In Embodiment 2, it is specified that the figure 1 An example in which the duty ratio R is changed in the initial stage of film formation of the microcrystalline silicon thin film in the microcrystalline semiconductor thin film manufacturing apparatus shown.

[0092] Using the microcrystalline semiconductor thin film manufacturing method (SiH 4 In the microcrystalline silicon thin film of the gas pulse method), for example, the high-frequency power is turne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com