Processing Technology of High Strength and High Conductivity Pure Copper Wire

A processing technology and high-conductivity technology, applied in the field of material forming and processing, can solve the problems of difficult structure materials to meet various application requirements, low electrical conductivity and tensile strength, loose pure copper structure, etc., to achieve uniform pure copper strength and elongation performance, improved electrical conductivity, and the effect of low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

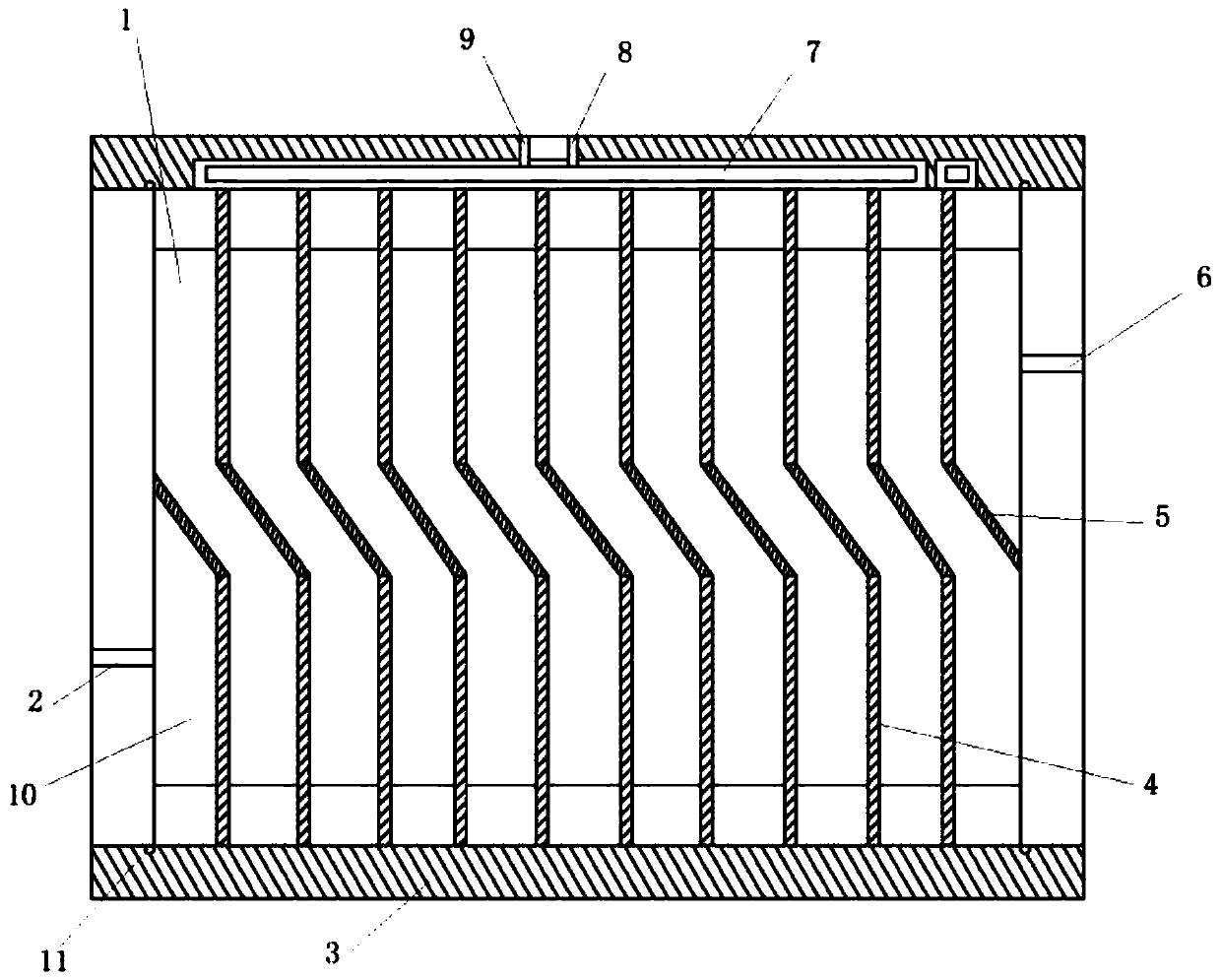

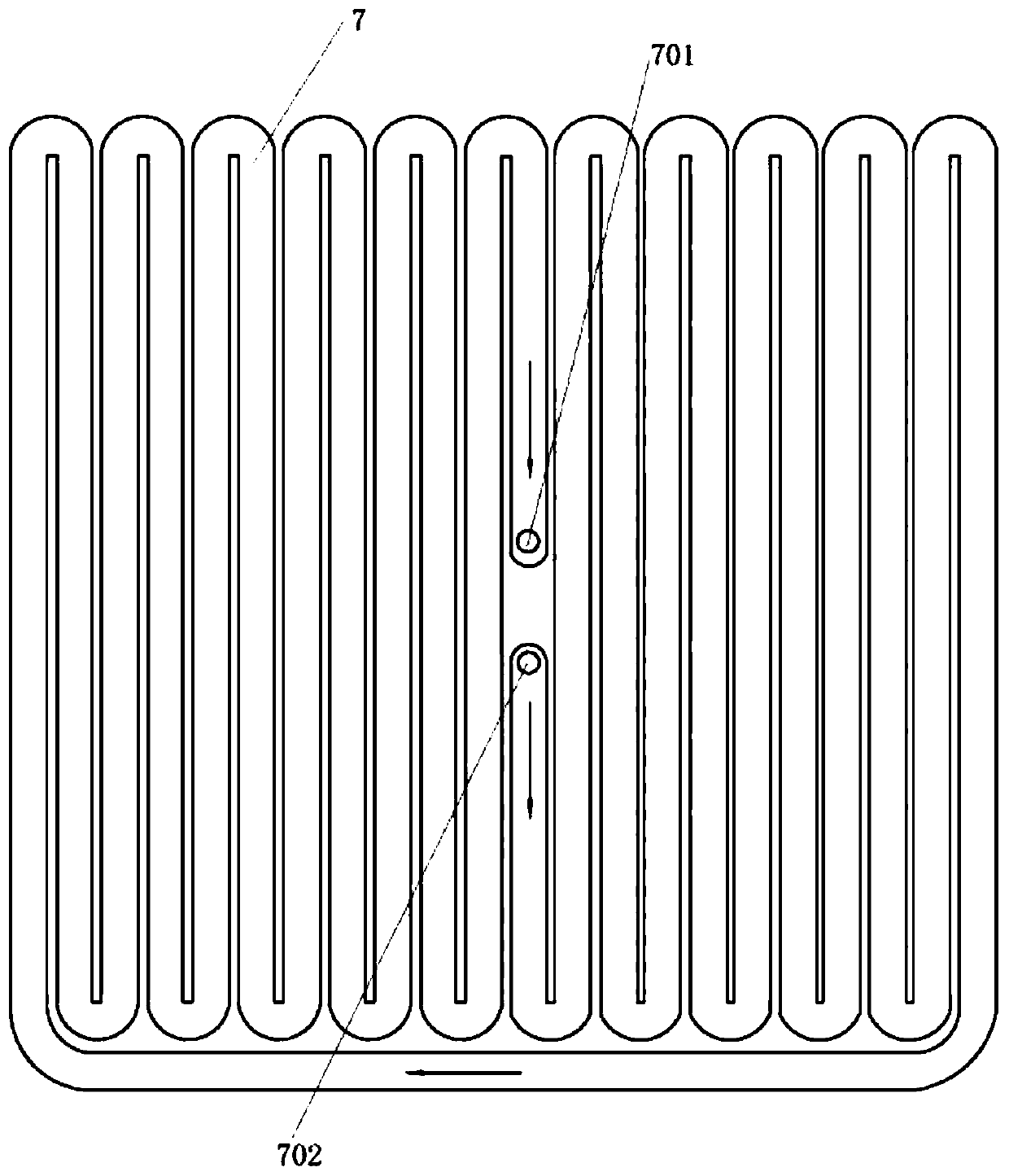

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

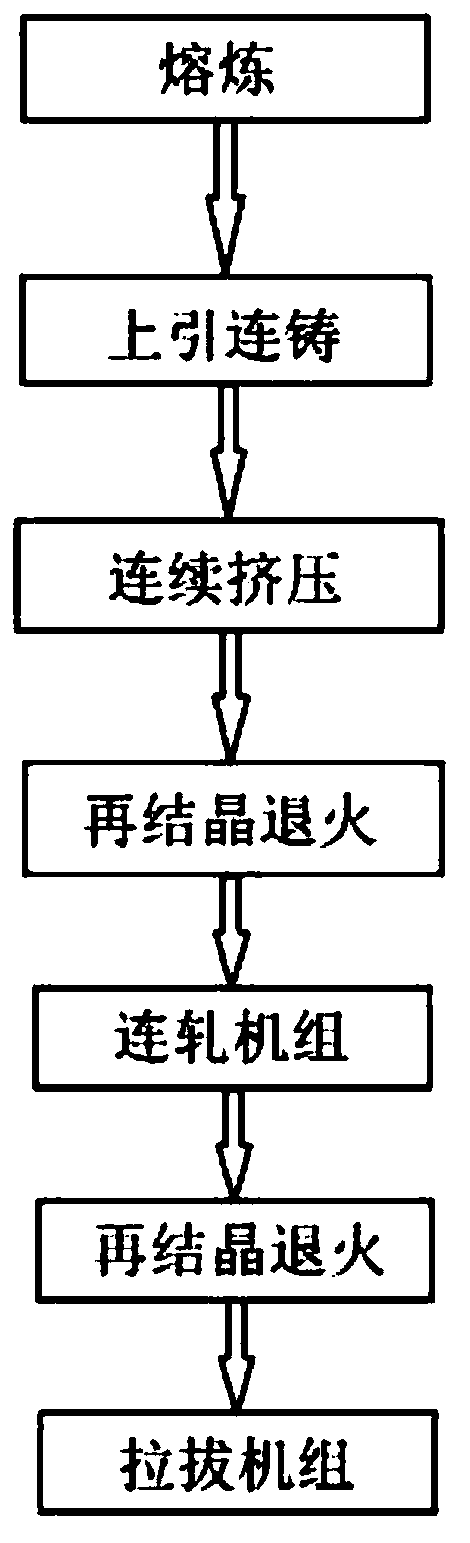

[0025] Such as figure 1 Shown, the processing technique of high-strength high-conductivity pure copper wire of the present invention comprises the following steps:

[0026] (1) Electrolytic copper is used as raw material, and it is melted in a smelting device after drying. The melting temperature is 900°C-1200°C. Charcoal and graphite flakes are used to cover the surface of the copper liquid to ensure the vacuum state during melting, and the online degassing, Deoxygenation, stirring, the online degassing, deoxidation, stirring process refers to filling the copper liquid with 99.999% argon or nitrogen through the online degassing device, and through the controlled rotating graphite shaft and rotor, the metering The argon or nitrogen gas is pressed into the copper liquid and broken up into tiny bubbles, so that it can be evenly dispersed in the copper liquid, so as to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com