TCR soft start and SVC dynamic reactive power compensation device and soft start and dynamic reactive power compensation method

A compensation device and soft start technology, applied in electric power, oil field high voltage motor soft start and power grid reactive power compensation, metallurgy, mining fields, can solve the problems of large area of liquid resistance, high noise, large maintenance, etc. And the effect of low operating cost, easy operation and maintenance, and reduced input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

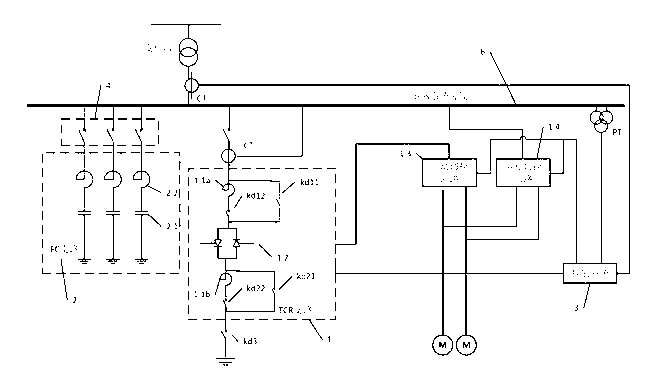

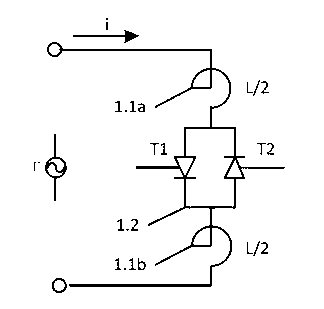

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, a TCR soft start and SVC dynamic reactive power compensation device includes: a TCR branch 1, an FC branch 2, a start switching circuit 1.3, a running switching circuit 1.4 and a control system 3; TCR branch 1 includes The first phase-controlled reactor unit, the thyristor valve group unit 1.2, the second phase-controlled reactor unit, the first switch kd11 and the second switch kd21; the first phase-controlled reactor unit, the thyristor valve group unit 1.2 and the second phase-controlled The reactor units are connected in series in sequence, the first switch kd11 is connected in parallel with the first phase-controlled reactor unit, the second switch kd21 is connected in parallel with the second phase-controlled reactor unit, and the first phase-controlled reactor unit is controlled by the first phase-controlled reactor unit The reactor 1.1a is connected in series with the first isolating sw...

Embodiment 2

[0038] The difference with embodiment 1 is: as image 3 combined with figure 1 , there are three motors M. The start-up switching circuit 1.3 is composed of a switch group, which starts three motors M1, M2 and M3 respectively, wherein: the switch K2.1 corresponds to the motor M1, the switch K2.2 corresponds to the motor M2, and the switch K2.2 corresponds to the motor M3 is switch K2.3; the switches of the operation switching circuit 1.4 of motor M1, motor M2 and motor M3 are respectively switch K3.1, switch K3.2, and switch K3.3; the present embodiment starts switch K2 and operation switch K3 It is a high voltage switch that accepts control system 3 digital control switches and closures.

[0039] When the motor M1 is started: the high-voltage circuit breaker receives the closing signal of the control system, the switch K2.1 is closed, and the thyristor valve group unit 1.2 receives the control system 3 to adjust the firing angle signals of the thyristor T1 and thyristor T2 ...

Embodiment 3

[0042] Carry out the method for soft start and dynamic reactive power compensation with TCR soft start of the present invention and SVC dynamic reactive power compensation device, its steps are:

[0043] A. In the starting state of the motor M: the control system 3 controls the start switching circuit 1.3 to close the corresponding start switch K2, and the thyristor valve group unit 1.2 in the TCR branch 1 becomes the soft start device of the motor M, realizing the power grid under the bus 6 Soft start of one or several motors M;

[0044] B. When the start-up state of the motor M ends, when the motor M enters operation: the control system 3 controls the operation switch circuit 1.4 to close the corresponding operation switch K3, and then the control system 3 controls the start switch circuit 1.3 to separate the start switch K2, and the motor M is officially enter the running state;

[0045] C. When the motor M is idle or when the motor M officially enters the running state: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com