A ZN-SB-TE phase transformer-changing film material and preparation method for phase-changing memory

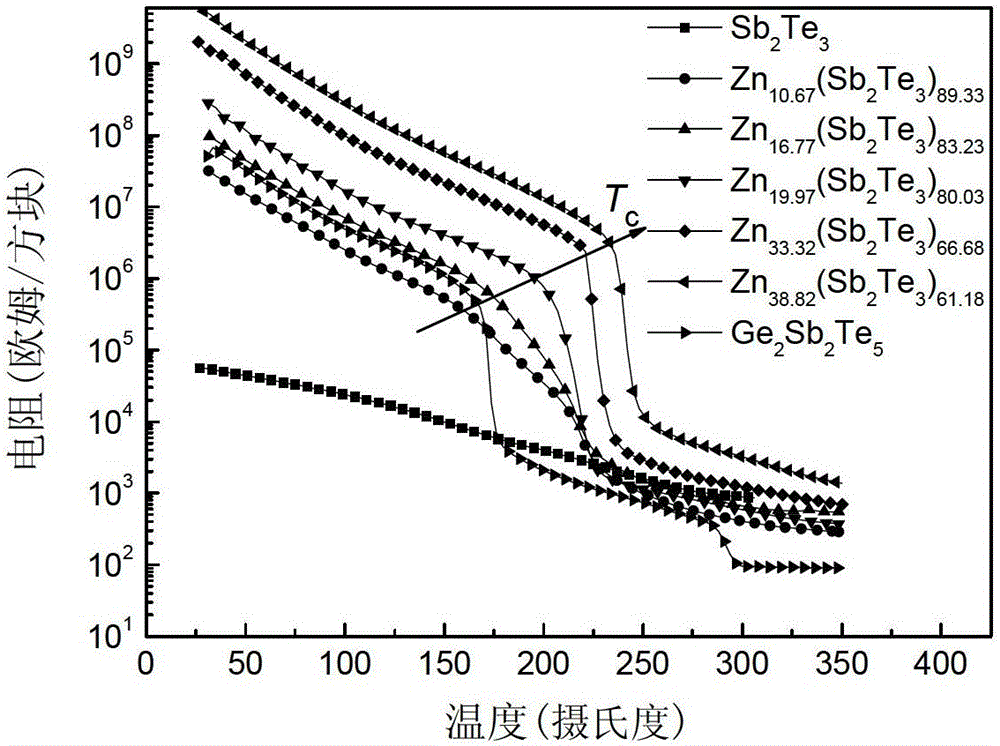

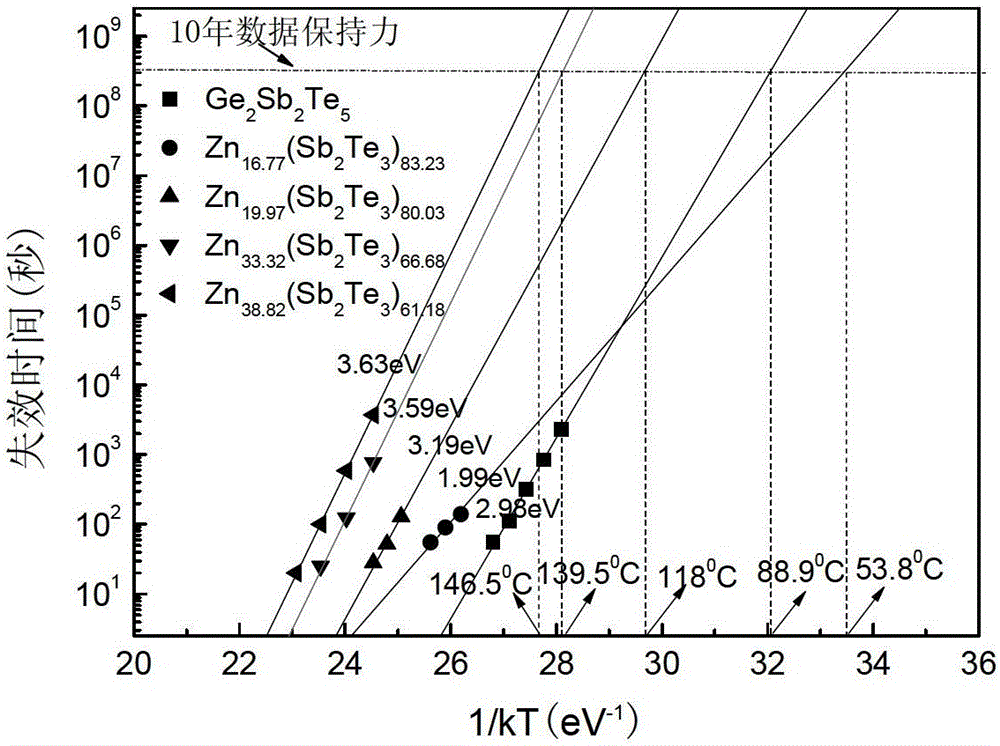

A phase change memory, zn-sb-te technology, applied in electrical components and other directions, can solve problems such as affecting the PRAM data access speed and reliability, poor stability of N-Sb-Te, and insignificant phase change mutation points. , to achieve the effect of improving crystallization temperature and data retention ability, fast crystallization speed, and easy industrialized large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

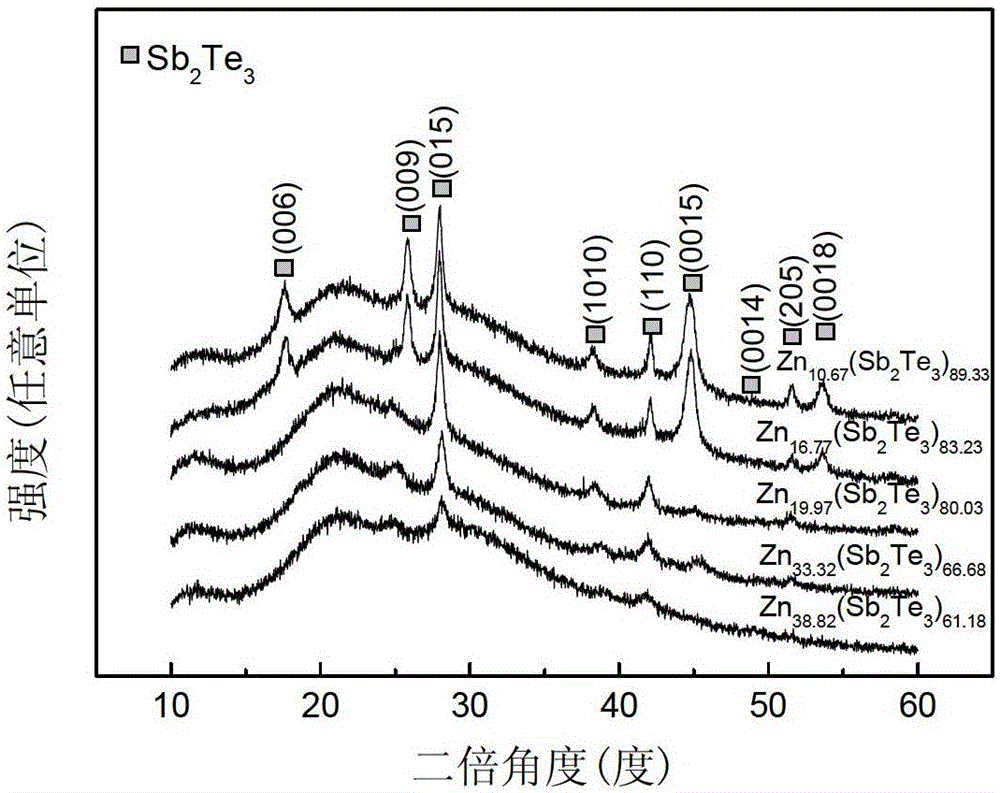

[0028] A Zn-Sb-Te phase-change memory film material for phase-change memory according to the present invention is composed of three elements Zn, Sb and Te, and the three elements of zinc, antimony and tellurium in the phase-change material are two by two bonds to form a ternary system.

Embodiment 2

[0030] A kind of Zn-Sb-Te phase-change memory film material used for phase-change memory of the present invention, its general chemical structure formula is Zn X (Sb 2 Te 3 ) 100-X , where 0<x<40, the specific preparation method is as follows:

[0031] In the magnetron sputtering coating system (JGP-450 type), the zinc single target is installed in the magnetron direct current (DC) sputtering target, and the Sb 2 Te 3 The target is installed in the magnetron radio frequency (RF) sputtering target, and the quartz sheet or silicon oxide sheet is used as the substrate. The sputtering chamber of the magnetron sputtering coating system is vacuumed until the vacuum degree of the chamber reaches 1.6×10 -4 Pa, and then pass high-purity argon gas with a volume flow rate of 47.6ml / min (SCCM standard milliliter per minute) into the sputtering chamber until the air pressure in the sputtering chamber reaches the required ignition pressure of 0.3Pa for sputtering, and then control the a...

Embodiment 3

[0033] With above-mentioned embodiment 2, its difference is: in the preparation process alloy Sb 2 Te 3 The sputtering power of the target is controlled to 80W, and the sputtering power of the Zn single target is controlled to 0W, and the Sb 2 Te 3 Phase change memory thin film material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com