Niobium microalloyed steel for low-temperature reinforcing steel bar and rolling process of steel

A technology of micro-alloying and low-temperature steel bars, which is applied in the direction of temperature control, etc., to achieve the effect of low nickel content and good low-temperature resistance of steel types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

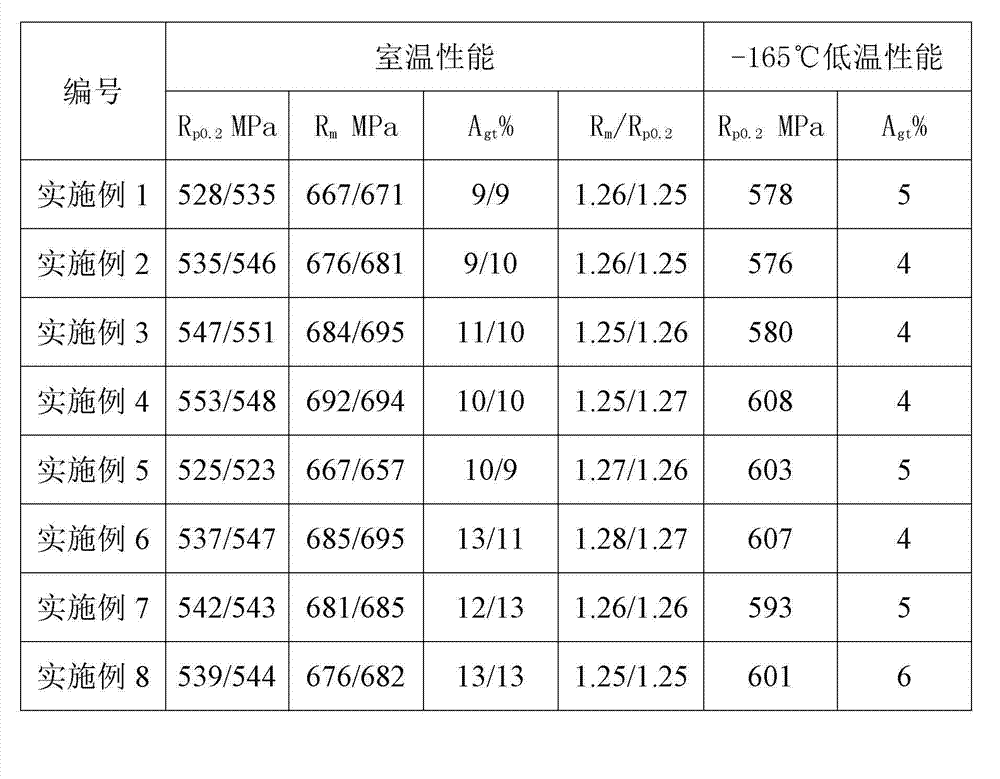

Examples

Embodiment 1

[0031] The chemical composition ratio of the niobium microalloyed steel for low-temperature reinforcement is: C: 0.10%, Si: 0.35%, Mn: 1.58%, P: 0.007%, S: 0.006%, Ni: 0.55% , Cu: 0.75%, Nb: 0.027%, and the rest are Fe and impurity elements.

[0032] Taking a steel billet with a diameter of φ12mm as an example, the rolling process of the low-temperature steel bar with a diameter of φ12mm is based on the above composition range, smelted in an electric arc furnace, refined outside the furnace, continuously cast, and then rolled on a continuous bar rolling mill forming.

[0033] The rolling process parameters of the niobium microalloyed low-temperature steel bars are: billet heating temperature 1181-1205°C, starting rolling temperature 980-1002°C, finishing rolling temperature 956-972°C, water cooling after rolling, upper cooling bed temperature 610-620°C ℃, steel bars are bundled and stacked after natural cooling on the cooling bed.

Embodiment 2

[0035] The chemical composition ratio of the niobium microalloyed steel for low temperature steel bars is: C: 0.11%, Si: 0.33%, Mn: 1.48%, P: 0.008%, S: 0.005%, Ni: 0.88% , Cu: 0.16%, Nb: 0.028%, and the rest are Fe and impurity elements.

[0036] Taking a steel billet with a diameter of φ16mm as an example, the rolling process of the low-temperature steel bar with a diameter of φ16mm is based on the above composition range, smelting in a converter and refining outside the furnace, continuous casting, and rolling on a continuous bar rolling mill. .

[0037] The rolling process parameters of the niobium microalloyed low-temperature steel bars are: billet heating temperature 1210-1230°C, starting rolling temperature 1023-1033°C, finishing rolling temperature 1010-1027°C, water cooling after rolling, upper cooling bed temperature 550-575°C ℃, steel bars are bundled and stacked after natural cooling on the cooling bed.

Embodiment 3

[0039] The chemical composition ratio of the niobium microalloyed steel for low temperature steel bars is: C: 0.12%, Si: 0.18%, Mn: 1.51%, P: 0.009%, S: 0.007%, Ni: 0.90% , Cu: 0.12%, Nb: 0.033%, and the rest are Fe and impurity elements.

[0040] Taking a steel billet with a diameter of φ20mm as an example, the rolling process of the low-temperature steel bar with a diameter of φ20mm is based on the above composition range, smelted in an electric arc furnace, refined outside the furnace, continuously cast, and then rolled on a continuous bar rolling mill forming.

[0041]The rolling process parameters of the niobium microalloyed low-temperature steel bar are: billet heating temperature 1220-1240°C, starting rolling temperature 1020-1040°C, final rolling temperature 1026-1036°C, water cooling after rolling, upper cooling bed temperature 597-618 ℃, steel bars are bundled and stacked after natural cooling on the cooling bed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com