Distiller condenser for brewing white spirits

A technology of condenser and liquor, applied in the preparation of alcoholic beverages, etc., can solve the problems of easy occurrence of safety accidents, waste of water resources, unsealed cold water barrels, etc., and achieve the improvement of production environment, automatic control of wine temperature, and water saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

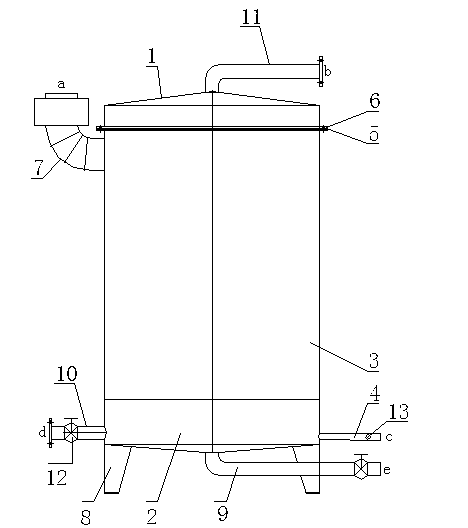

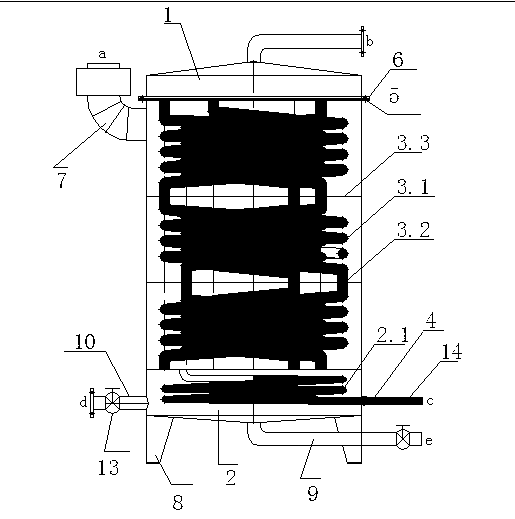

[0010] The distillation condenser for brewing liquor according to the present invention, the specific implementation mode is described as follows with reference to the accompanying drawings:

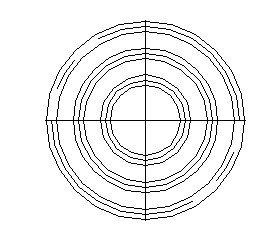

[0011] The structure of the distillation condenser for brewing liquor mainly includes: hot water layer 1, cold water layer 2, wine outlet spiral tube 2.1, shell 3, spiral tube 3.1, flow partition a3.2, flow partition b3.3, outlet Wine pipe 4, sealing gasket 5, flange 6, steam inlet pipe 7, corner column 8, sewage pipe 9, water inlet pipe 10, water outlet pipe 11, solenoid valve 12, temperature sensor 13, the shell 3 is barrel-shaped, divided into upper , middle and lower areas, the top is the hot water layer 1, which is connected and sealed by the gasket 5 and the top of the flange 6 and the shell 3, the top of the hot water layer 1 is provided with a hot water outlet pipe 11, the bottom is the cold water layer 2, and the cold water There is a wine outlet spiral tube 2.1 in the cavity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com