Processing method for fresh bone with combination of heavy pressure extraction and biological enzymolysis

A processing method and bio-enzyme technology, applied in the field of food processing, can solve the problems of low resource utilization, easy pollution, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

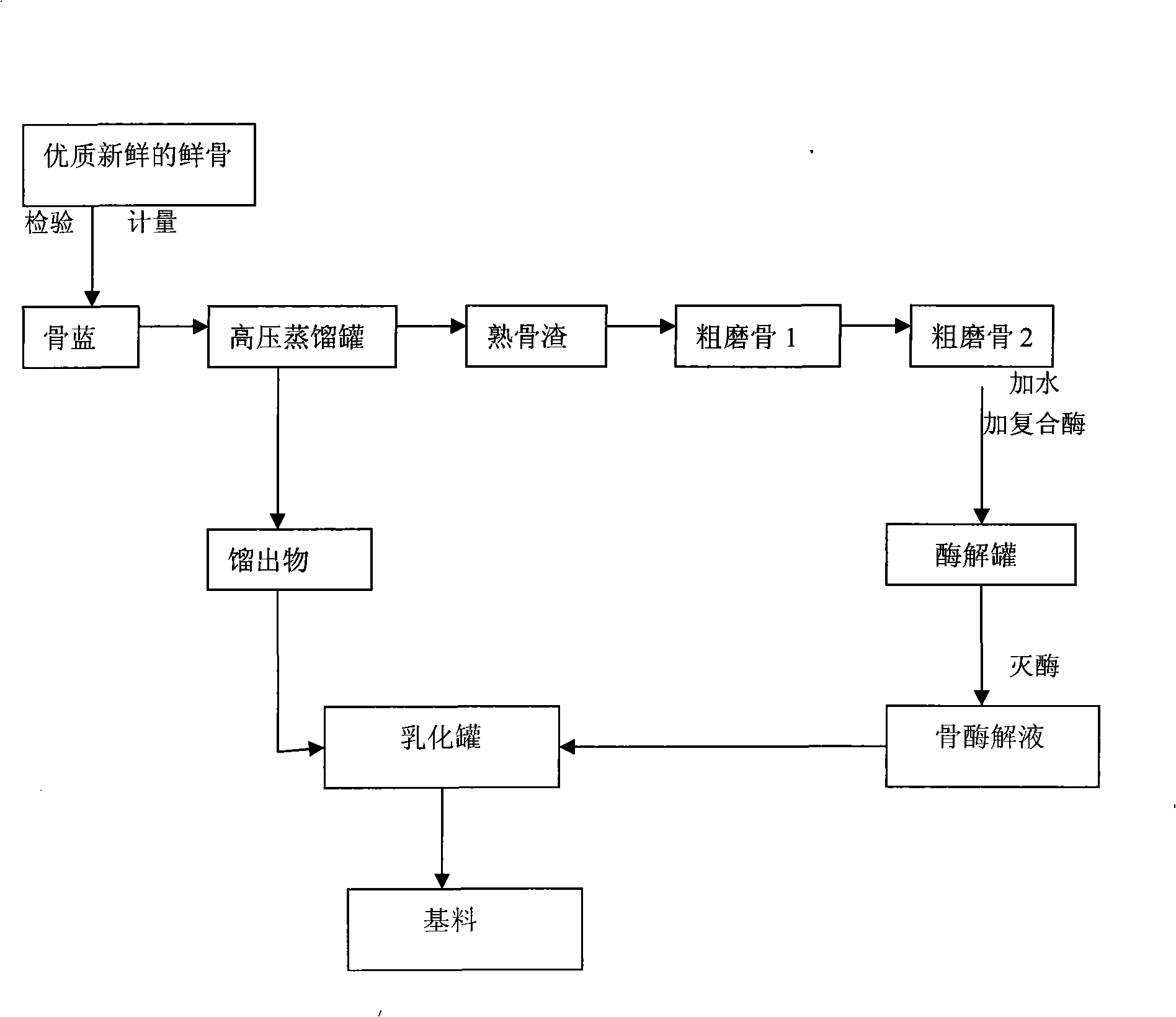

[0012] The specific embodiment of the present invention will be described in detail below in conjunction with the process flow diagram.

[0013] As shown in the accompanying drawings, the present invention uses steam heating (dry steaming without adding water), extraction and enzymatic hydrolysis to process, and the bones are graded and ground and combined with enzymatic hydrolysis, thermal reaction, emulsification, enzyme elimination, and sterilization. Obtain fresh bone extract, its specific method is realized by the following steps:

[0014] (1) Distillation of material selection: select the fresh bones of livestock and poultry shortly after slaughter, such as chicken bones, pork bones or beef bones, etc., without any rot and deterioration, put them into the bone basket, and put the fresh bones directly through the guide rail and the bone basket Put it into a high-pressure distillation tank, use steam at a pressure of 0.15Mpa-0.30Mpa, and steam the bones for 612 hours under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com