Method for preparing fuel gas by burning biomass

A biomass and gas technology, which is applied in the manufacture of combustible gas, combustible gas purification, combustible gas purification/transformation, etc., can solve problems such as clogging of reaction tubes, and achieve the effect of increasing gas production rate and reducing tar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

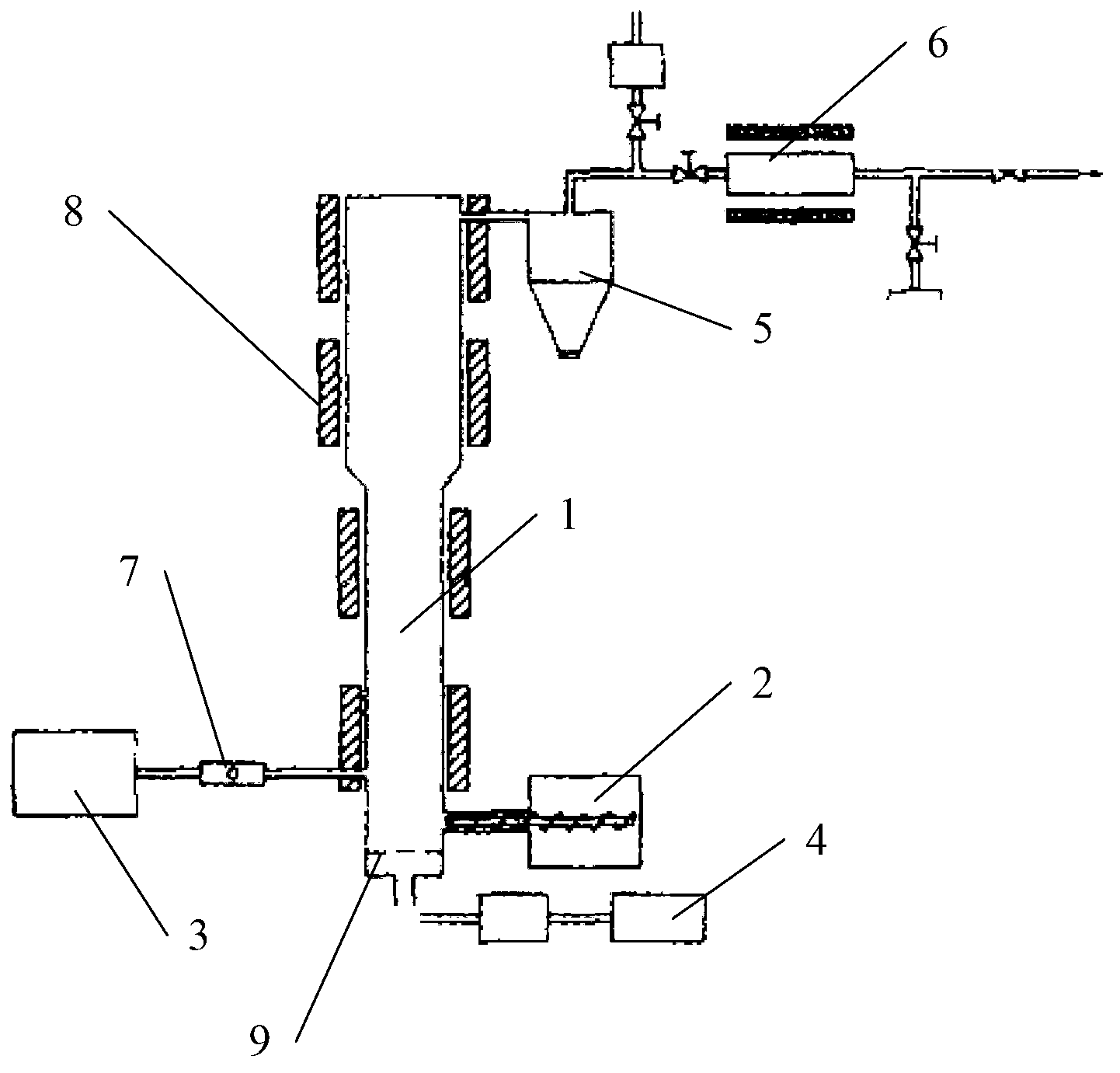

Method used

Image

Examples

preparation example Construction

[0051] The preparation of the calcined dolomite catalyst is as follows: crush the dolomite, screen out particles with a particle size of 0.3-0.45 mm, and calcinate at a temperature of 900° C. for 4 hours.

[0052] The carbon nanotube (CNT) grafted Fe-NiO / TiO 2 The concrete preparation method of catalyst is as follows:

[0053] The first step, Fe-NiO / TiO 2 Preparation of catalyst, weigh 68g tetrabutyl titanate solution, add 377mL absolute ethanol and 26.75g nitric acid, stir to obtain solution A; 0.404gFe(NO 3 ) 3 9H 2 O,2.619g Ni(NO 3 )2·6H 2 O was dissolved in 215mL deionized water to obtain solution B. Add solution B dropwise to solution A, stir for 2h, let stand for 20h, and dry at 120°C. Raise the temperature to 500°C at a rate of 3°C / min, and roast for 3h. Preparation Fe-NiO / TiO 2 ;

[0054] In the second step, take the prepared Fe-NiO / TiO 2 10g is placed in a fluidized bed reactor, and the nitrogen flow rate is adjusted to 5L / min to fluidize the catalyst. The te...

Embodiment 1

[0063] The preparation of embodiment 1 calcined dolomite

[0064] Crush the dolomite, screen out particles with a particle size of 0.3-0.45mm, and calcinate at 900°C for 4 hours to obtain the product.

Embodiment 2

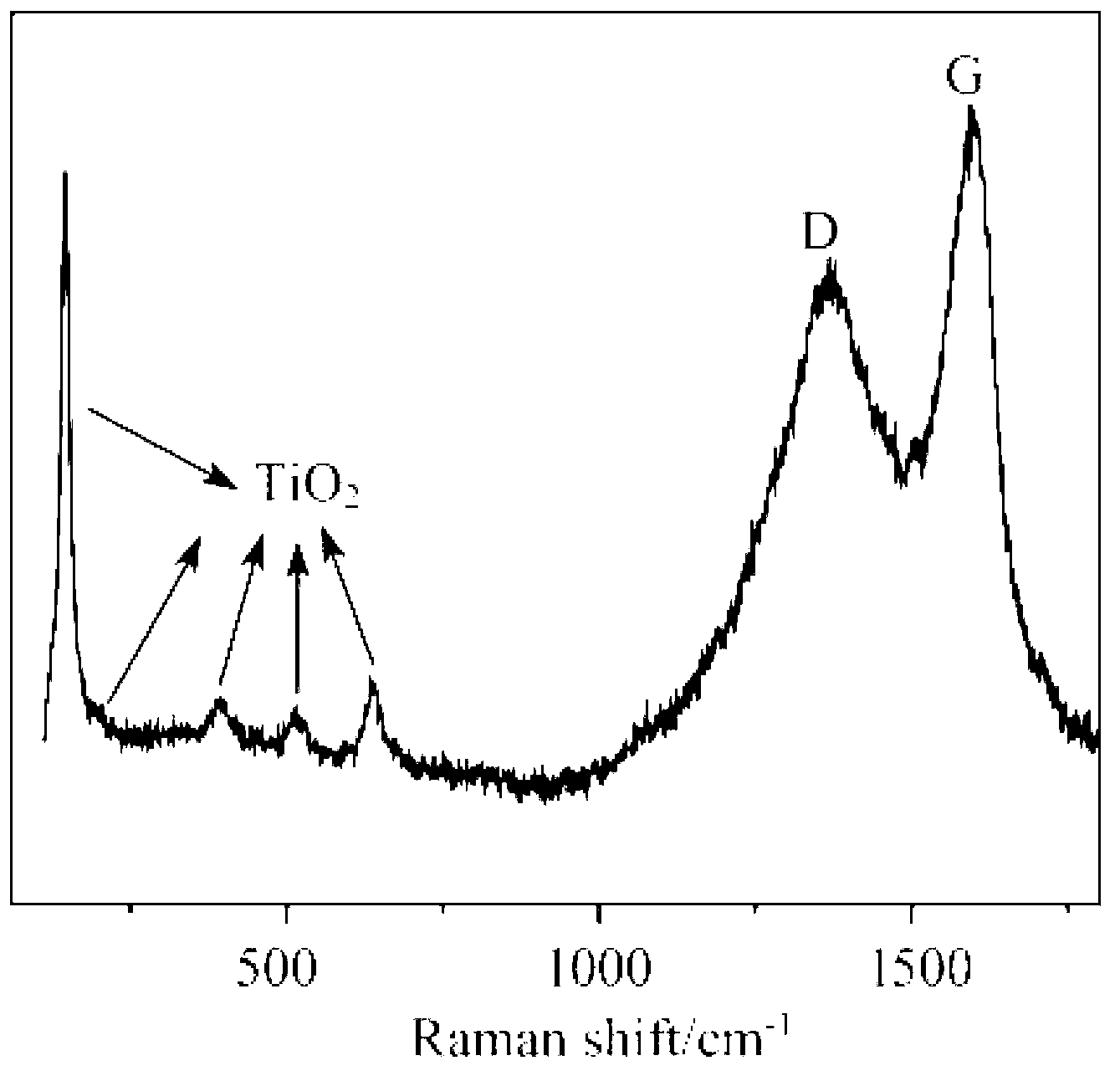

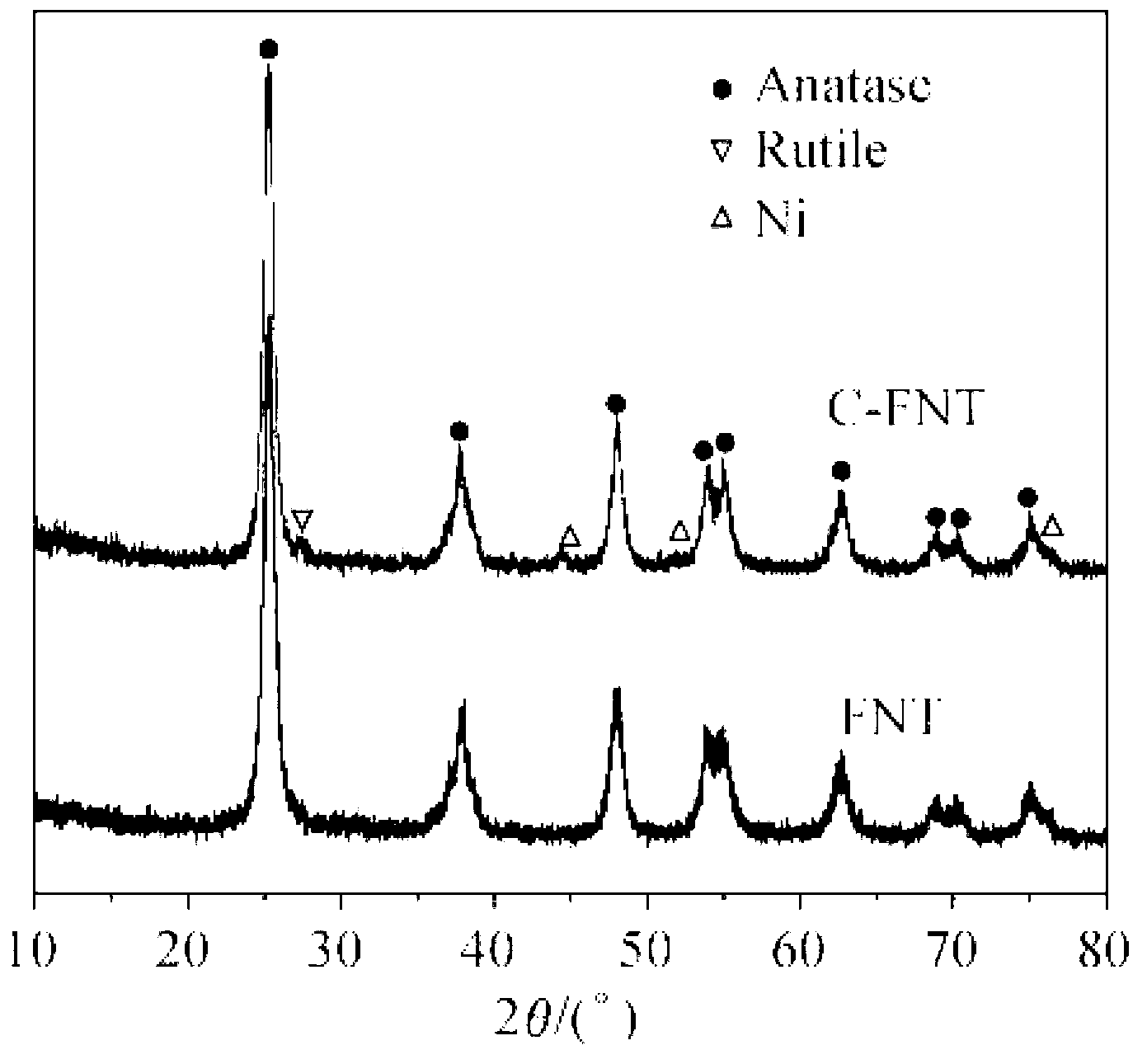

[0065] Example 2 Fe-NiO / TiO grafted with carbon nanotubes (CNT) 2 Catalyst preparation

[0066] The surface characteristics of the catalyst were analyzed by ASAP2010 specific surface and pore size analyzer (Micrometrics).

[0067]Weigh 68g tetrabutyl titanate solution, add 377mL absolute ethanol and 26.75g nitric acid, stir to obtain solution A; 0.404gFe(NO 3 ) 3 9H 2 O,2.619g Ni(NO 3 ) 2 ·6H 2 O was dissolved in 215mL deionized water to obtain solution B. Add solution B dropwise to solution A, stir for 2h, let stand for 20h, and dry at 120°C. Raise the temperature to 500°C at a rate of 3°C / min, and roast for 3h. Preparation Fe-NiO / TiO 2 , the prepared Fe-Ni / TiO 2 The comparative area is 63.0m 2 / g, take the prepared Fe-NiO / TiO 2 Put 10g of catalyst in a fluidized bed reactor, adjust the flow rate of nitrogen gas to 5L / min to fluidize the catalyst. Raise the temperature to 500°C, and after the temperature in the reactor is stabilized, feed acetylene gas into the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com