Method for preparing polypeptide-polylactic acid-polyethyleneglycol dual-graft copolymer

A technology of graft copolymer and polyethylene glycol, which is applied in the field of preparation of biodegradable polymer materials, achieves the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

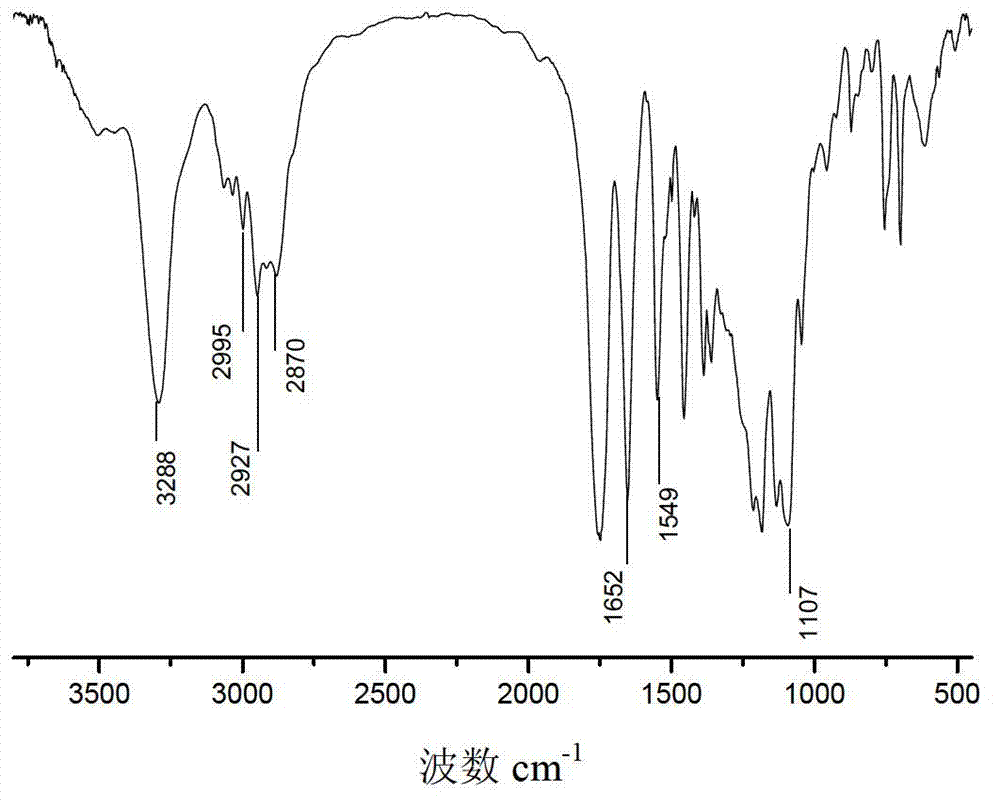

Image

Examples

Embodiment 1

[0017] Embodiment 1, adopt the following steps:

[0018] 1) Synthesis of polypeptide-polylactic acid graft copolymer

[0019] Add 8 grams of poly(γ-benzyl-L-glutamate) with a molecular weight of 20000, 6.1 grams of poly(L-lactic acid) monolauryl ether with a molecular weight of 1000, and 1.75 grams of para Toluenesulfonic acid, then add 200 milliliters of 1,1,2-trichloroethane solvent, under inert atmosphere, stir and react at 55°C for 3 days, terminate the reaction, then obtain the target object by filtration, dialysis, and drying. The molecular weight is 25235.

[0020] 2) Synthesis of polypeptide-polylactic acid-polyethylene glycol double graft copolymer:

[0021] Add 7 grams of polypeptide-polylactic acid graft copolymer, 2.8 grams of polyethylene glycol monomethyl ether with a molecular weight of 500 and 1.21 grams of p-toluenesulfonic acid into the drying reactor, and then add 140 milliliters of 1,1,2-tris Ethyl chloride solvent, under an inert atmosphere, stirred and...

Embodiment 2

[0025] 1) Synthesis of polypeptide-polylactic acid graft copolymer

[0026] Add 7 grams of poly(γ-ethyl-L-glutamate) with a molecular weight of 30,000, 7 grams of poly(L-lactic acid) monolauryl ether with a molecular weight of 1500, and 1.21 grams of p-toluene into the dry reactor. Sulphonic acid and 180 milliliters of dimethyl sulfoxide solvent, under inert atmosphere, stirred and reacted at 56 ° C for 4 days, terminated the reaction, and then obtained the target object by filtration, dialysis, and drying. The molecular weight of the target object was 35644.

[0027] 2) Synthesis of polypeptide-polylactic acid-polyethylene glycol double graft copolymer:

[0028] Add 6 grams of polypeptide-polylactic acid graft copolymer, 2.6 grams of polyethylene glycol monomethyl ether and 0.91 grams of p-toluenesulfonic acid with a molecular weight of 600 in the drying reactor, and then add 130 milliliters of dimethyl sulfoxide solvent, Under an inert atmosphere, stirred and reacted at 57°...

Embodiment 3

[0031] 1) Synthesis of polypeptide-polylactic acid graft copolymer

[0032] Add 9 grams of poly(γ-methyl-L-glutamate) with a molecular weight of 50,000, 8.8 grams of poly(L-lactic acid) monolauryl ether with a molecular weight of 2000, and 1.35 grams of p-toluene into the dry reactor. Sulphonic acid and 250 milliliters of 1,1,2-trichloroethane solvent, under an inert atmosphere, stirred and reacted at 58° C. for 3 days, terminated the reaction, and then obtained the target object by filtration, dialysis, and drying. The molecular weight of the target object was 56756.

[0033] 2) Synthesis of Polypeptide-Polylactic Acid-Polyethylene Glycol Double Graft Copolymer

[0034] Add 8 grams of polypeptide-polylactic acid graft copolymer, 2.8 grams of polyethylene glycol monomethyl ether with a molecular weight of 700 and 1.05 grams of p-toluenesulfonic acid into the drying reactor, and then add 150 milliliters of 1,1,2-tris Ethyl chloride solvent, under an inert atmosphere, stirred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com