Method for preparing oxygen fluorine chlorine tellurate glass with intermediate infrared fluorescence output at 4 mu m

A technology of oxyfluorochlorotellurite and its realization method, which is applied in the application field of mid-infrared rare earth doped luminescent glass, to achieve the effects of improving the forming ability, improving the fluorescence lifetime, and improving the pumping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

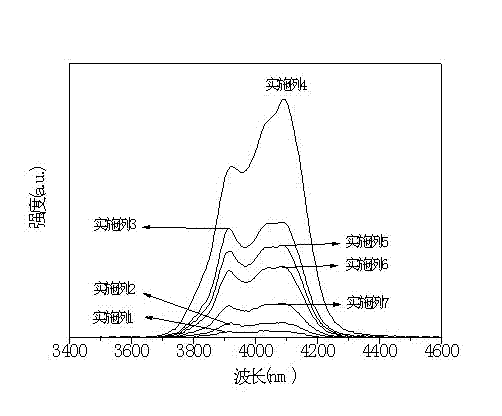

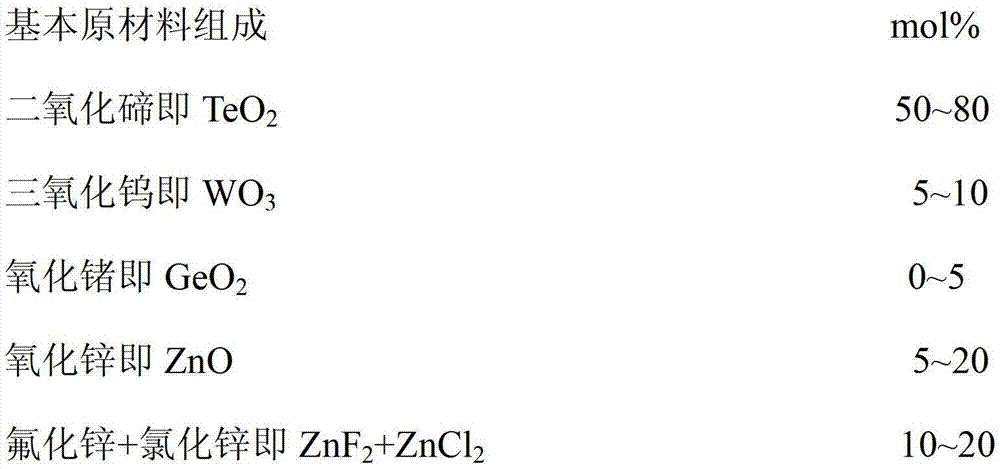

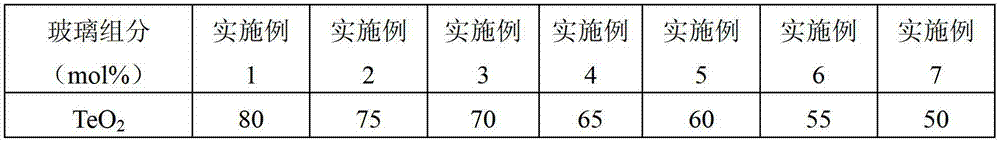

[0033] All components of the glass are: TeO 2 : 80mol%, WO 3 : 5mol%, ZnO: 5mol%, ZnCl 2 : 10mol%, Ho 2 O3: 0.02mol%, Yb 2 o 3 : 0.5mol%, of which rare earth Ho 2 o 3 , Yb 2 o 3 All are introduced in the form of external doping, accurately calculated, weighed and mixed according to the formula. Put the above mixture into a covered gold crucible, and put it in an electric furnace for melting, the atmosphere is air, the melting temperature is 760-900°C, and the melting time is 15-20min; Molded on a copper plate or a stainless steel mold, then annealed at 260 ° C for 2 hours to eliminate internal stress, and then cooled with the furnace. The thermal stability parameter ΔT (°C) of the sample prepared in Example 1 reaches 102°C, the glass has good glass-forming performance, and the fluorescence spectrum is shown in figure 1 .

Embodiment 2

[0035] All components of the glass are: TeO 2 : 75mol%, WO 3 : 5mol%, GeO 2 : 5mol%, ZnO: 5mol%, ZnF 2 : 10mol%, Ho 2 o 3 : 0.02mol%, HoF 3 : 0.02mol%, Yb 2 o 3 : 0.25mol%, YbF 3 : 0.25mol%, of which rare earth Ho 2 o 3 、HoF 3 , Yb 2 o 3 , YbF 3All are introduced in the form of external doping, accurately calculated, weighed and mixed according to the formula. Put the above mixture into a covered gold crucible, and put it in an electric furnace for melting, the atmosphere is air, the melting temperature is 760-900°C, and the melting time is 15-20min; Molded on a copper plate or a stainless steel mold, then annealed at 260 ° C for 2 hours to eliminate internal stress, and then cooled with the furnace. The thermal stability parameter ΔT (°C) of the sample prepared in Example 2 reaches 105°C, the glass has good glass-forming performance, and the fluorescence spectrum is shown in figure 1 .

Embodiment 3

[0037] All components of the glass are: TeO 2 : 70mol%, WO 3 : 10mol%, ZnO: 5mol%, ZnF 2 : 10mol%, ZnCl 2 : 5mol%, HoF 3 : 0.1mol%, YbF 3 : 1.5mol%, of which rare earth HoF 3 , YbF 3 All are introduced in the form of external doping, accurately calculated, weighed and mixed according to the formula. Put the above mixture into a covered gold crucible, and put it in an electric furnace for melting, the atmosphere is air, the melting temperature is 760-900°C, and the melting time is 15-20min; Molded on a copper plate or a stainless steel mold, then annealed at 260 ° C for 2 hours to eliminate internal stress, and then cooled with the furnace. The thermal stability parameter ΔT (°C) of the sample prepared in Example 3 reaches 110°C, the glass has good glass-forming performance, and the fluorescence spectrum is shown in figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com