Method and device for treating organic oil-containing wastewater

A treatment device and organic technology, which is applied in the field of organic oily wastewater treatment and organic oily wastewater treatment equipment, can solve problems such as oily wastewater is prone to clogging, reactor blockage, foul smell, and substrate conversion rate, etc., to achieve landscape Good effect, small footprint, strong pretreatment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

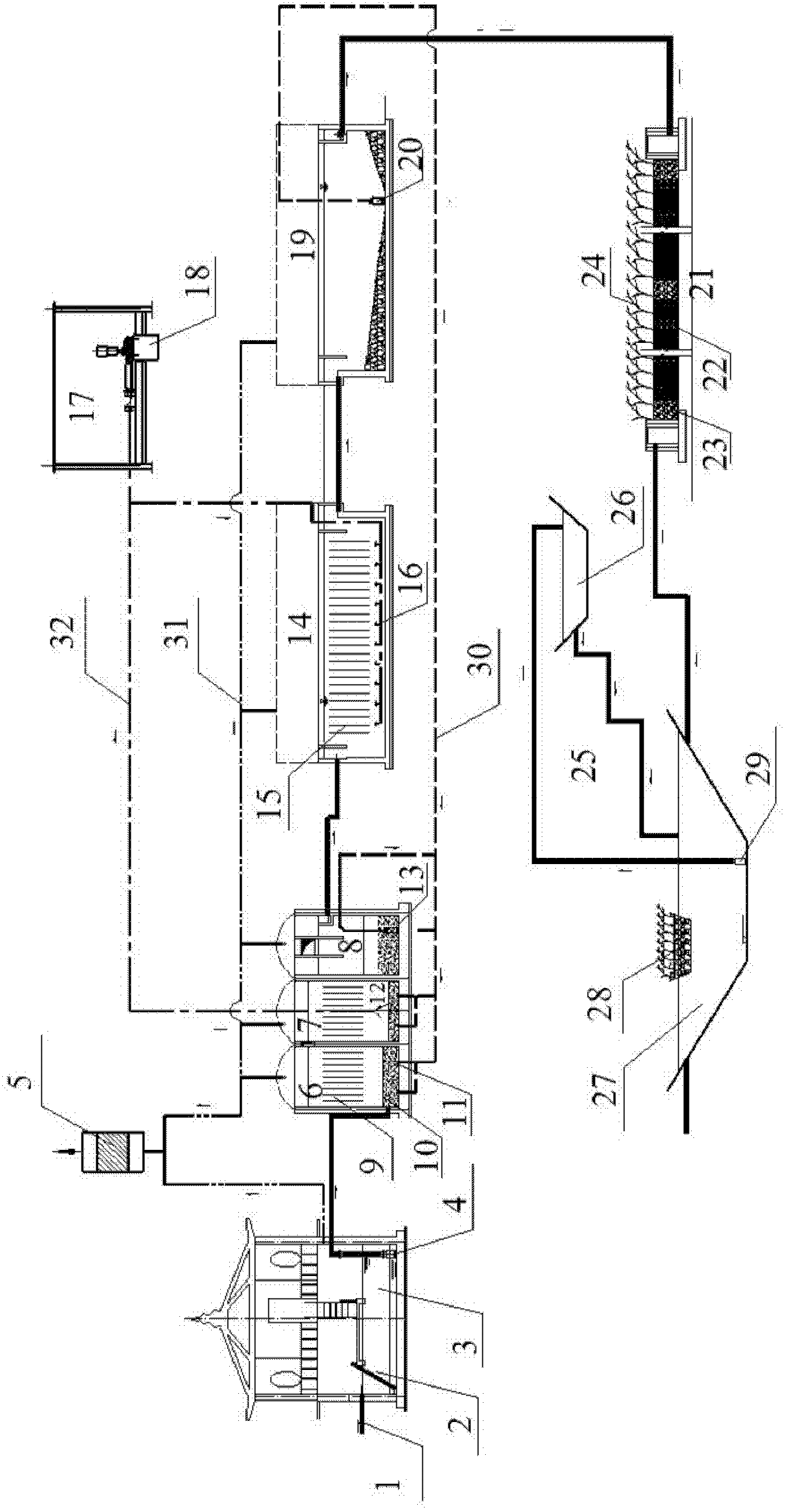

[0033] The treatment device provided by the invention mainly includes:

[0034] Multi-functional regulating pool, hydraulic retention time ≥ 4 hours, stainless steel plane grille is installed at the water inlet end of the regulating pool, and the grid gap is 30mm; a submersible sewage pump is installed behind the regulating pool, which is used to transport the anaerobic and anoxic biological iron-carbon reaction pool for inward electrolysis. Water, the internal electrolysis anoxic anoxic bio-iron-coke reaction pool of the present invention is divided into an internal electrolysis anaerobic bio-iron-coke reaction pool and an internal electrolysis anoxic bio-iron-coke reaction pool.

[0035] Both the internal electrolytic anaerobic biological iron-carbon reaction tank and the internal electrolytic anoxic biological iron-carbon reaction tank are hung with Φ120 and L1200 combined elastic fillers. The iron filler at the bottom of the pool is calculated at 20-30kg / kg COD, and the bio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com