Iron ferric oxide nanocomposite particles and its preparation method and application

A ferric oxide and nano-composite technology, applied in the direction of iron oxide/hydroxide, nanotechnology, ferrous oxide, etc., can solve problems such as liver and kidney damage, complicated process, calcium loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

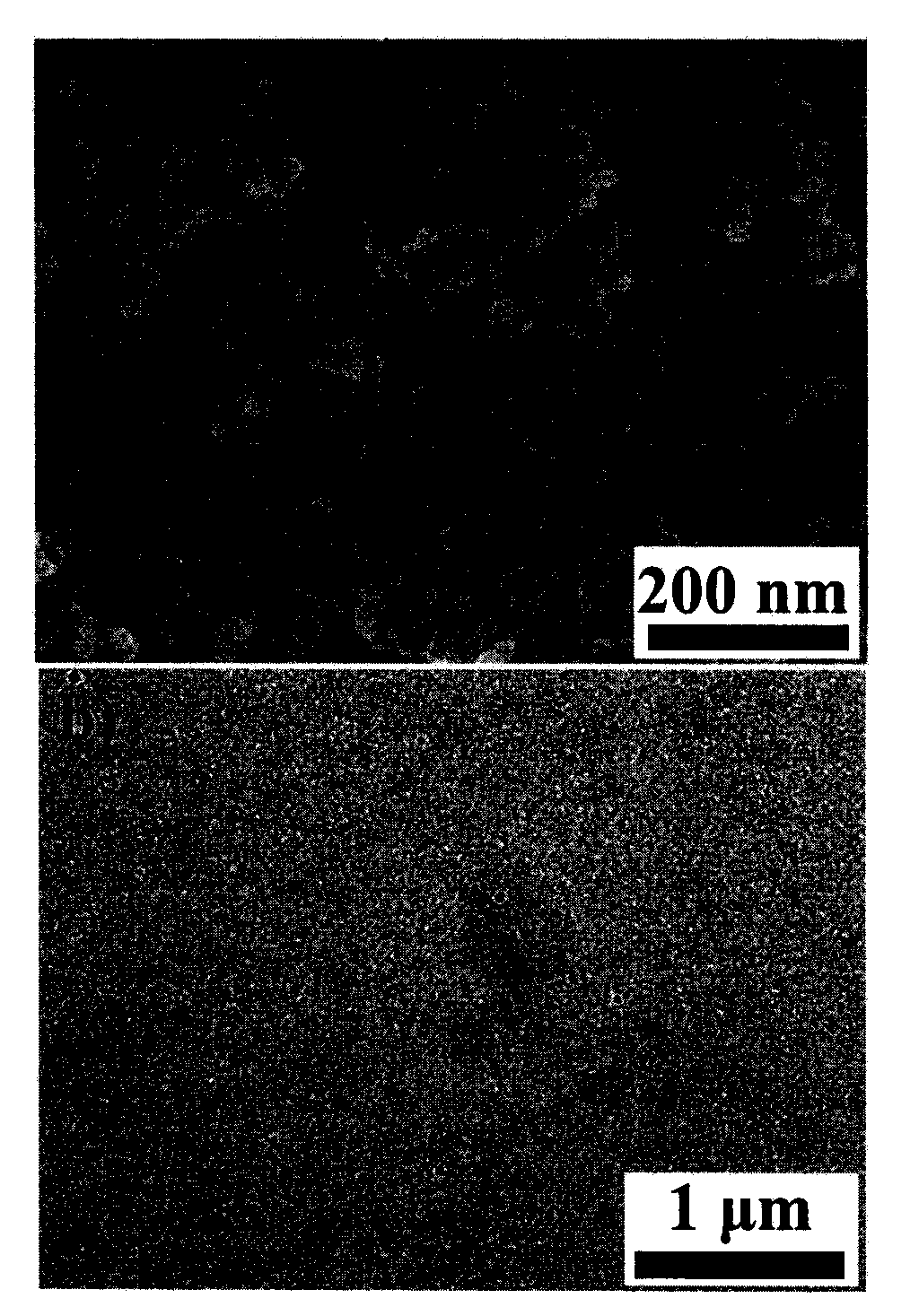

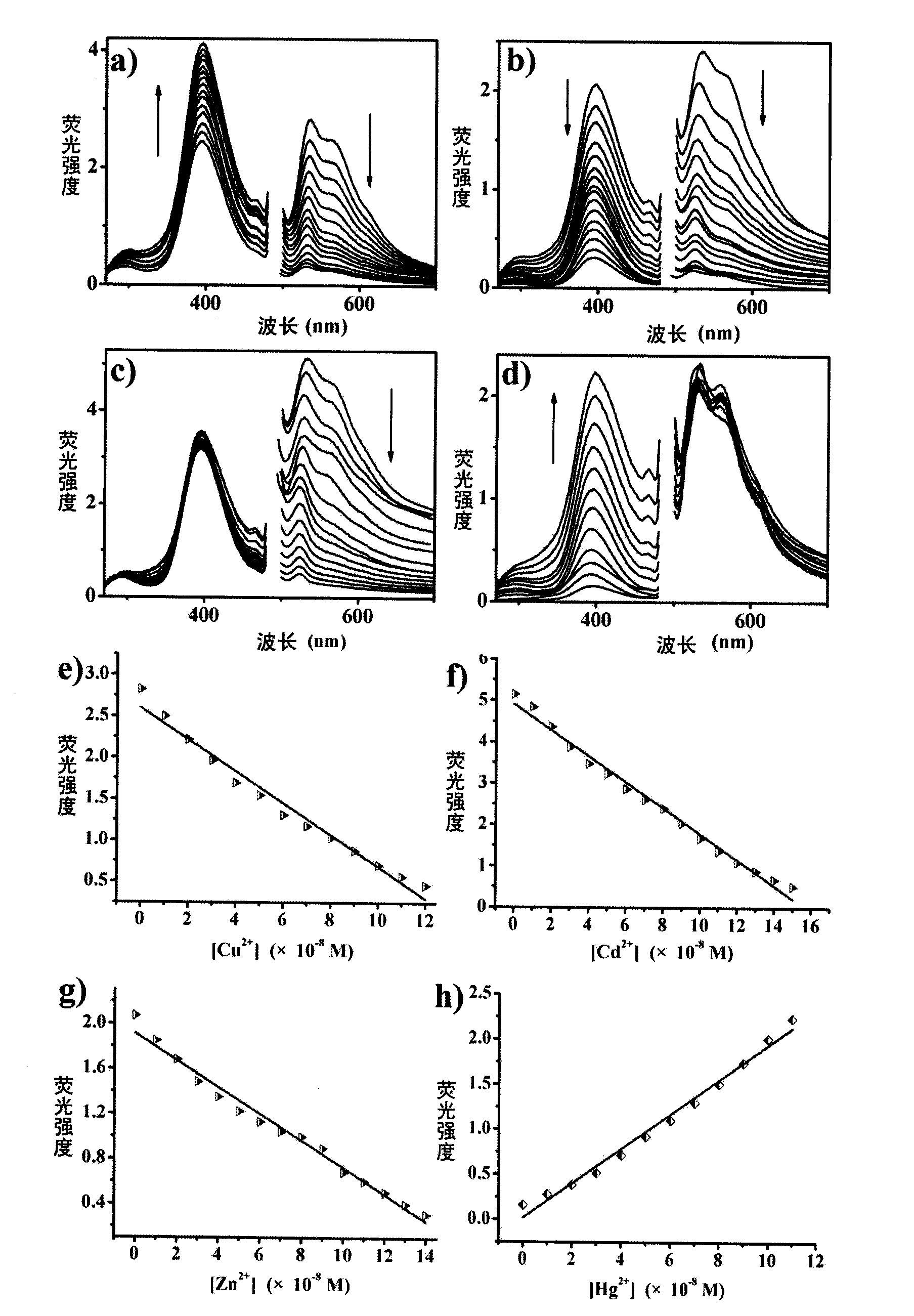

[0028] The concrete steps of preparation are:

[0029] Step 1, first according to the weight ratio of ferric chloride hexahydrate, sodium acetate, 1,6-hexanediamine and ethylene glycol is the ratio of 0.8:2.2:8:32, ferric chloride hexahydrate, sodium acetate and 1,6-hexanediamine were added to ethylene glycol and stirred until a clear solution was formed. Then put the transparent solution in a closed state, react at 180°C for 8 hours, and then perform solid-liquid separation, washing and drying; wherein, the solid-liquid separation treatment is magnetic separation, and the washing treatment is sequentially using ethanol and deionized Washed with water once, and dried at 20° C. to obtain ferric oxide nanoparticles.

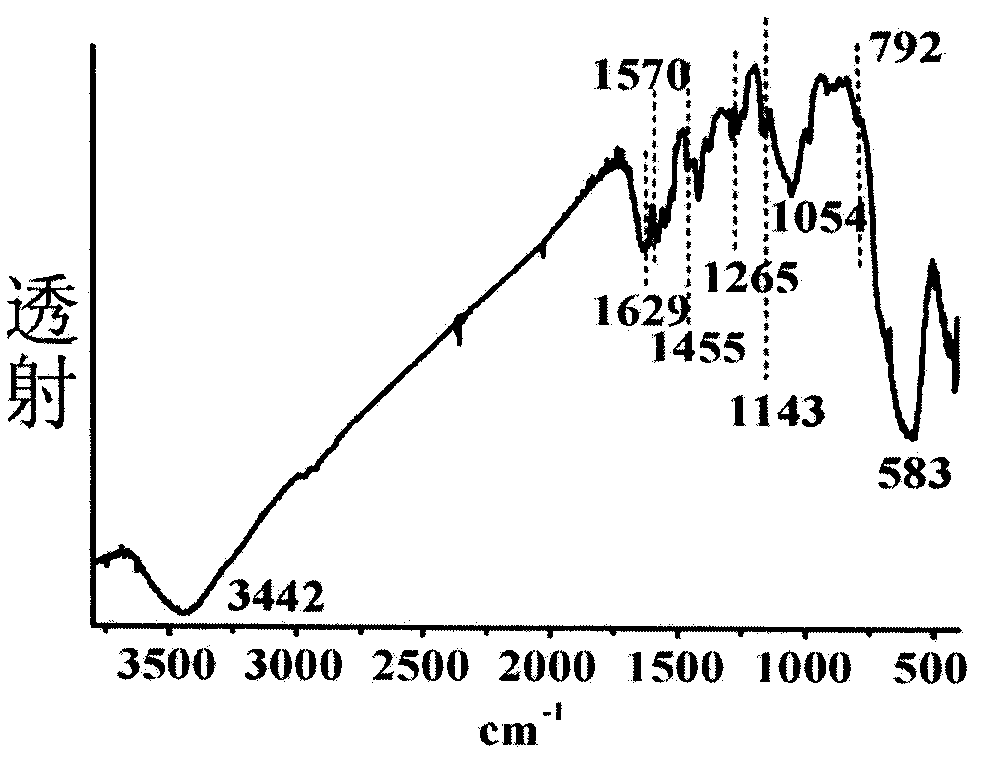

[0030] Step 2, first according to the weight ratio of 1,4-dihydroxyanthraquinone, chloroacetyl chloride and N,N-dimethylformamide is 0.22:0.6:38 ratio, 1,4-dihydroxyanthraquinone and chlorine Acetyl chloride was added to N,N-dimethylformamide and kept at 0°C for ...

Embodiment 2

[0033] The concrete steps of preparation are:

[0034] Step 1, first according to the weight ratio of ferric trichloride hexahydrate, sodium acetate, 1,6-hexanediamine and ethylene glycol is the ratio of 0.9:2.1:9:31, ferric trichloride hexahydrate, sodium acetate and 1,6-hexanediamine were added to ethylene glycol and stirred until a clear solution was formed. Then put the transparent solution in an airtight state, and after reacting at 190°C for 7.5 hours, it is subjected to solid-liquid separation, washing and drying; wherein, the solid-liquid separation treatment is magnetic separation, and the washing treatment is sequentially using ethanol and dehydration. The ion water was washed twice, and the drying treatment was to dry at 28° C. to obtain ferric oxide nanoparticles.

[0035] Step 2, first according to the weight ratio of 1,4-dihydroxyanthraquinone, chloroacetyl chloride and N,N-dimethylformamide is 0.23:0.5:39 ratio, 1,4-dihydroxyanthraquinone and chlorine Acetyl c...

Embodiment 3

[0038] The concrete steps of preparation are:

[0039] Step 1, first according to the weight ratio of ferric chloride hexahydrate, sodium acetate, 1,6-hexanediamine and ethylene glycol is the ratio of 1:2:10:30, ferric chloride hexahydrate, sodium acetate and 1,6-hexanediamine were added to ethylene glycol and stirred until a clear solution was formed. Then put the transparent solution in a closed state, react at 200°C for 7 hours, and then perform solid-liquid separation, washing and drying; wherein, the solid-liquid separation treatment is magnetic separation, and the washing treatment is sequentially using ethanol and deionized Washed with water for 3 times, and dried at 35° C. to obtain ferric oxide nanoparticles.

[0040]Step 2, first according to the weight ratio of 1,4-dihydroxyanthraquinone, chloroacetyl chloride and N,N-dimethylformamide is 0.24:0.4:40 ratio, 1,4-dihydroxyanthraquinone and chlorine Acetyl chloride was added to N,N-dimethylformamide and kept at 0°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com