Manufacturing method of energy product raw material and structure of energy product raw material

A technology of energy products and manufacturing methods, applied in printing, printing devices, etc., can solve problems such as difficult mixing, unstable quality, and high loss of raw materials, and achieve the effects of accelerating the aging process, accelerating blood flow, and maintaining natural balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

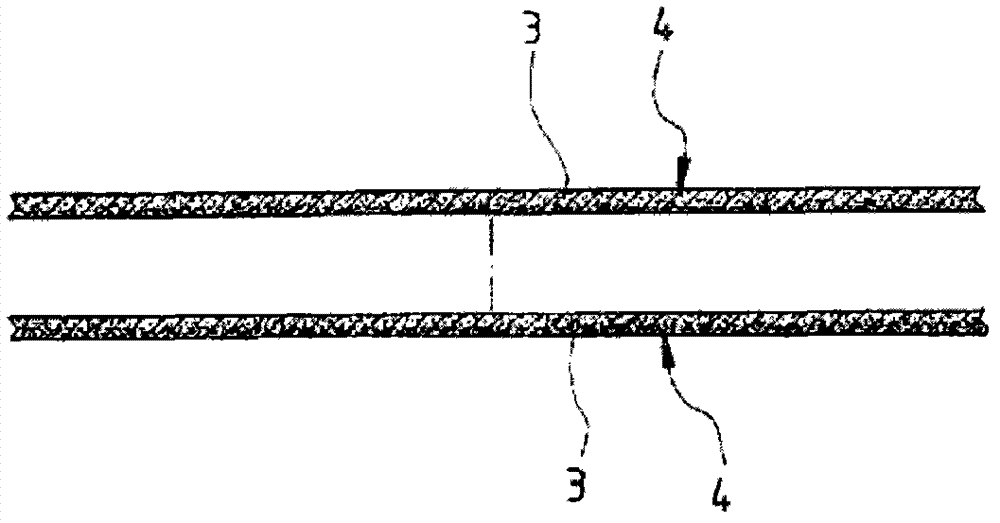

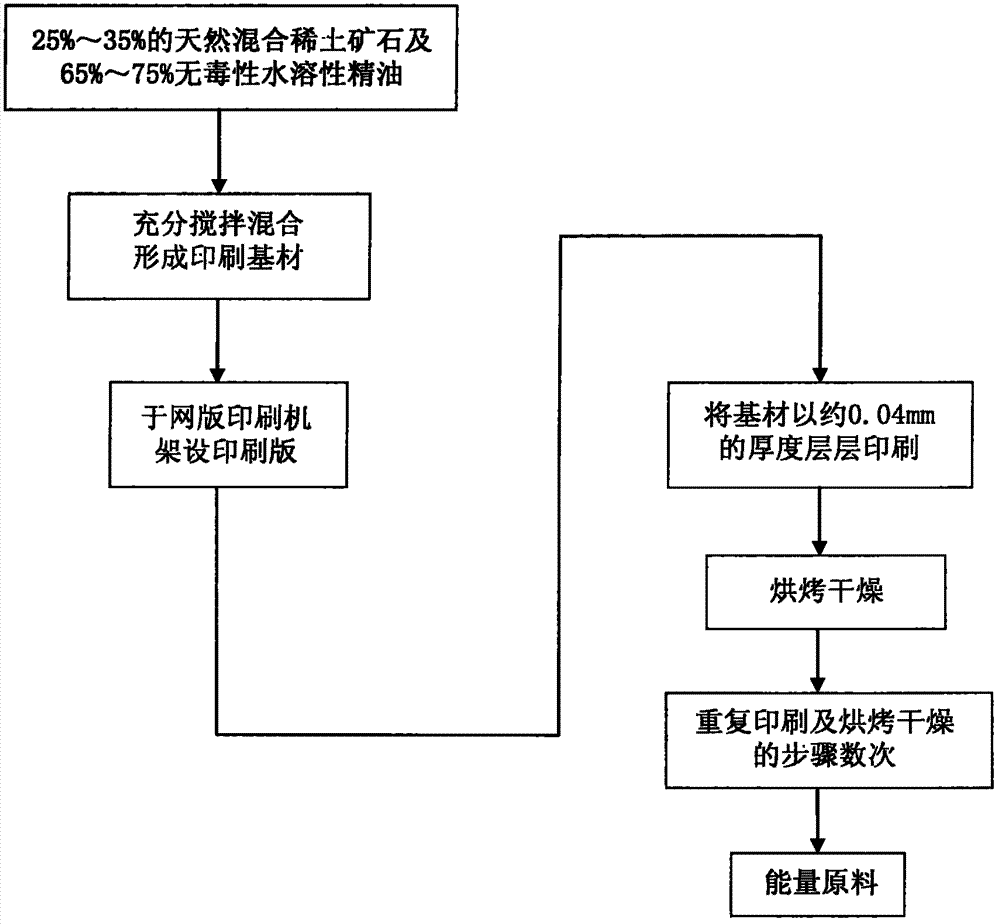

[0033] Please also see figure 2 and image 3 , is a manufacturing embodiment diagram and a manufacturing flow chart of the present invention. As shown in the figure, the manufacturing process of the present invention at least includes the following steps:

[0034] 1. Combine 25% to 35% of natural mixed rare earth ores (ore raw materials 3) and 65% to 75% of non-toxic water-soluble essential oils (also known as "water-based elastic penetrating" in the industry in mainland China, and water-based elastic penetrating is a kind of printing Paint, which is more commonly used in clothing printing) is fully stirred and mixed (to avoid ore precipitation) to form a substrate for printing 4.

[0035] 2. Set up the printing plate on the screen printing machine to ensure the graphics and size of the printing surface.

[0036] 3. Print the substrate 4 layer by layer on a screen printing machine with a thickness of about 0.04 mm, so that the thickness of each layer is controlled at 0.04 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com