Magnesium alloy honeycomb structure material and preparation method thereof

A honeycomb structure, magnesium alloy technology, applied in metal processing equipment, manufacturing tools, welding equipment and other directions, can solve problems such as being unsuitable for higher temperatures, and achieve the effects of low cost, simple equipment, and simplified procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

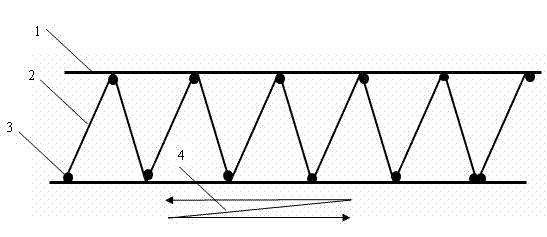

[0023] (1) Fabrication of the honeycomb core structure: the AZ31 board 2 with a thickness of 0.5mm is precisely bent and formed without damage to make the honeycomb core material.

[0024] (2) The surface of the panel and honeycomb core is soaked in NaOH solution with a volume fraction of 15% for 35 seconds, quickly taken out and soaked in HCL with a volume fraction of 15% for 40 seconds, taken out and dried to remove oil stains.

[0025] (3) Put the surface of the above connector into the liquid 3 solder Mg-0.15Zn container and heat it, the temperature rises to 350 degrees, and keep it warm for 3 minutes.

[0026] (4) Cooling: Put the wetted upper and lower plates 1 and the honeycomb in the semi-solid ultrasonic 4 for 45 seconds, and pressurize at 12 MPa. Cool to room temperature. The bonding strength is 25.2MPa. The honeycomb material can be used at a temperature below 250 degrees.

Embodiment approach 2

[0028] (1) Manufacture of honeycomb core structure: AZ31 with a thickness of 0.6mm is precisely bent and formed without damage to make a honeycomb core material.

[0029] (2) The surface of the panel and honeycomb core is soaked in NaOH solution with a volume fraction of 15% for 30 seconds, quickly taken out and soaked in HCL with a volume fraction of 15% for 40 seconds, taken out and dried to remove oil stains.

[0030] (3) Put the surface of the above-mentioned connecting piece into a container of liquid solder Mg-0.2Zn and heat it, the temperature rises to 400 degrees, and keep it warm for 4 minutes.

[0031] (4) Cooling: The upper and lower plates and the honeycomb that are wetted above are subjected to semi-solid ultrasonication for 50 seconds, and the pressure is 15 MPa. Cool to room temperature. The bonding strength is 27.4MPa. The honeycomb material can be used at a temperature below 300 degrees.

Embodiment approach 3

[0033] (1) Manufacture of honeycomb core structure: AZ31 with a thickness of 0.8mm is precisely bent and formed without damage to make a honeycomb core material.

[0034] (2) The surface of the panel and honeycomb core is soaked in NaOH solution with a volume fraction of 15% for 50 seconds, quickly taken out and soaked in HCL with a volume fraction of 15% for 60 seconds, taken out and dried to remove oil stains

[0035] (3) Put the surface of the above-mentioned connector into a container of liquid solder Mg-0.3Zn and heat it. The temperature rises to 500 degrees and keeps warm for 10 minutes.

[0036] (4) Cooling: The upper and lower plates and the honeycomb that are wetted above are subjected to semi-solid ultrasonication for 60 seconds and pressurized at 20 MPa. Cool to room temperature. The bonding strength is 32.3MPa. The honeycomb material can be used at a temperature below 300 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com